Inverted wedge type recoverable anchor rod

An inverted wedge and bolt technology, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of high requirements for surrounding rock conditions, limited scope of application, poor durability, etc., so as to improve the working life and pullout resistance Reasonable effect of bearing capacity and anchor stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

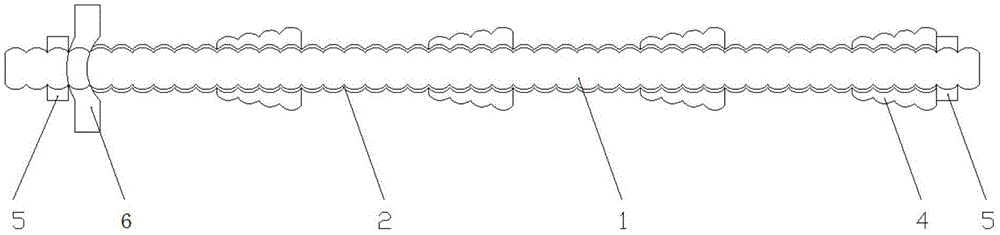

[0025] Such as figure 1 As shown, the inverted wedge type retrievable bolt is composed of a high-strength threaded rod body 1 and a threaded casing system 2. The threaded casing system 2 is welded as a whole by a seamless threaded steel pipe 3 and a frustum-shaped wedge 4. The high-strength threaded rod body 1 and the threaded sleeve system 2 are connected together through the threads between the two. Wherein the high-strength threaded rod body 1 is a whole-body threaded device processed from high-strength steel. One end of the high-strength threaded rod body 1 is used as an anchor section, and is fastened with a high-strength nut 5 , and the other end of the high-strength threaded rod body 1 is used as an anchor head, and is equipped with a tray 6 and a high-strength nut 5 .

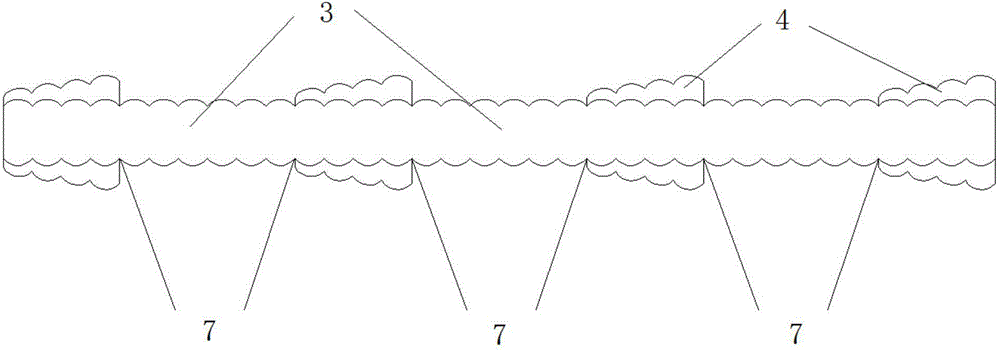

[0026] Such as figure 2 As shown, the threaded casing system 2 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com