Uplift bearing capacity testing device for miniature fiber bar uplift pile

A technology of pull-out bearing capacity and testing device, which is applied in the field of foundation foundation, and achieves the effects of low cost, large pull-out bearing capacity, and high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

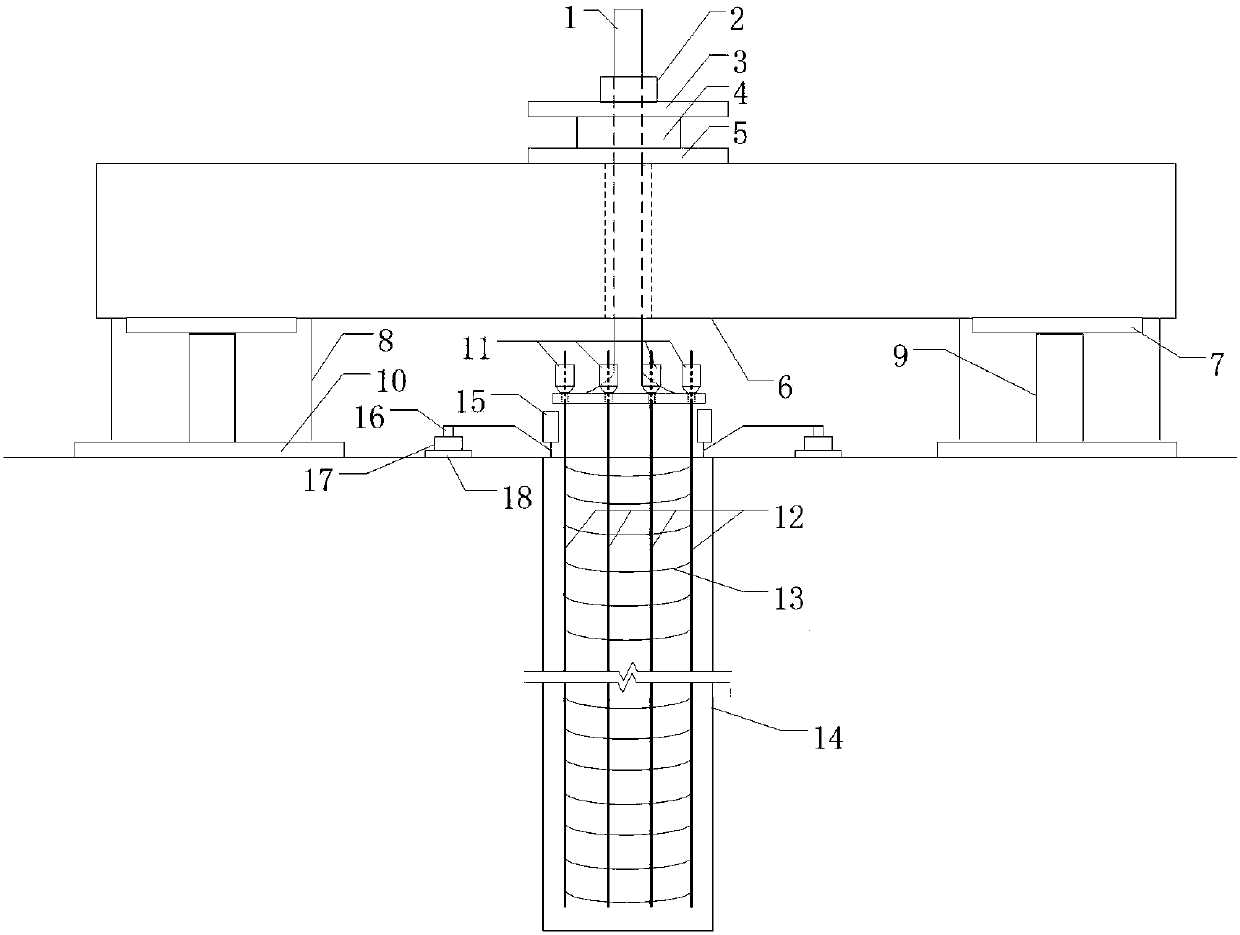

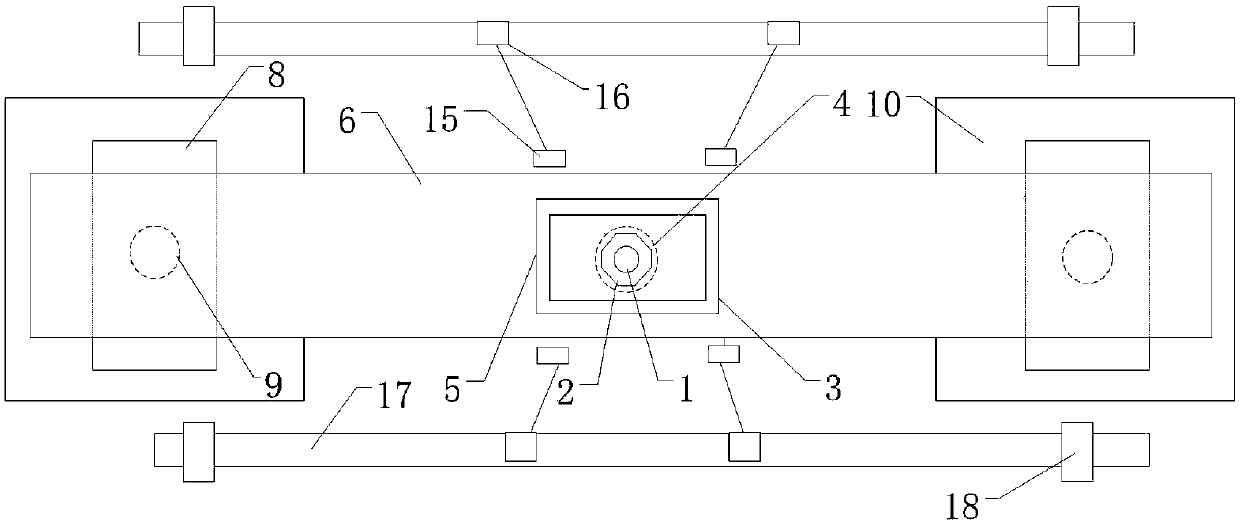

[0021] The main structure of the test device for the pull-out bearing capacity of fiber-reinforced miniature pull-out piles in this embodiment includes a high-strength drawing screw 1 with an enlarged head, a high-strength nut 2, a first steel backing plate 3, a load sensor 4, and a second steel backing plate 5 , Reaction beam 6, third steel backing plate 7, beam stool 8, jack 9, jack backing plate 10, fiber reinforcement lock head 11, fiber reinforcement 12, stirrup 13, pile hole 14, displacement sensor 15, magnetic table base 16. Datum beam 17 and buttress 18; high-strength drawing screw 1 with enlarged head is a rigid solid structure composed of a screw shaft and a bottom enlarged head. The diameter of the screw shaft is determined by the bearing capacity of the miniature uplift pile, about 60- 80mm, the expansion head is in the shape of a disk, with a thickness of 50mm, and a number of holes are made on the edge. The diameter of the hole is determined by the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com