Plane sliding propelling device for shield tunneling machine

A technology of propulsion device and shield machine, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low reuse rate, damage to brackets, and high consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a planar sliding propulsion device for a shield machine, which can realize continuous propulsion and improve propulsion efficiency.

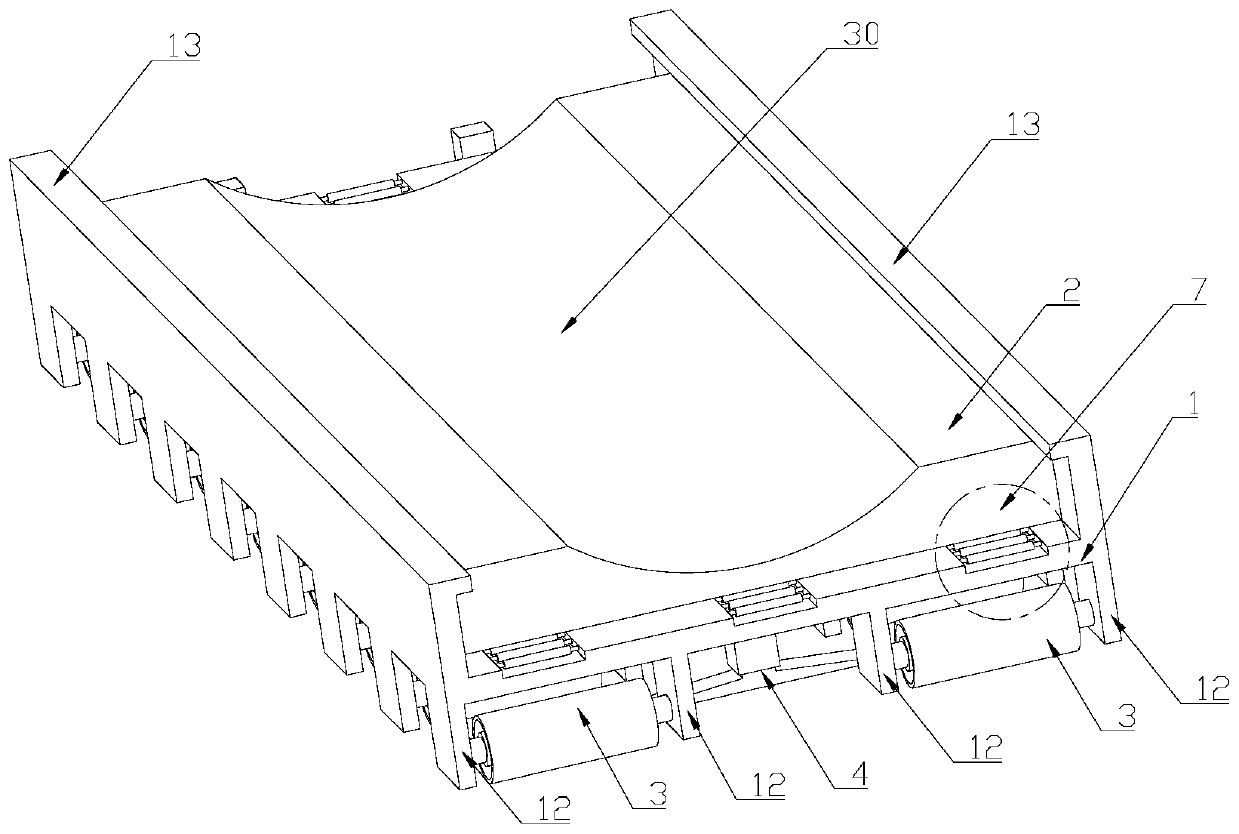

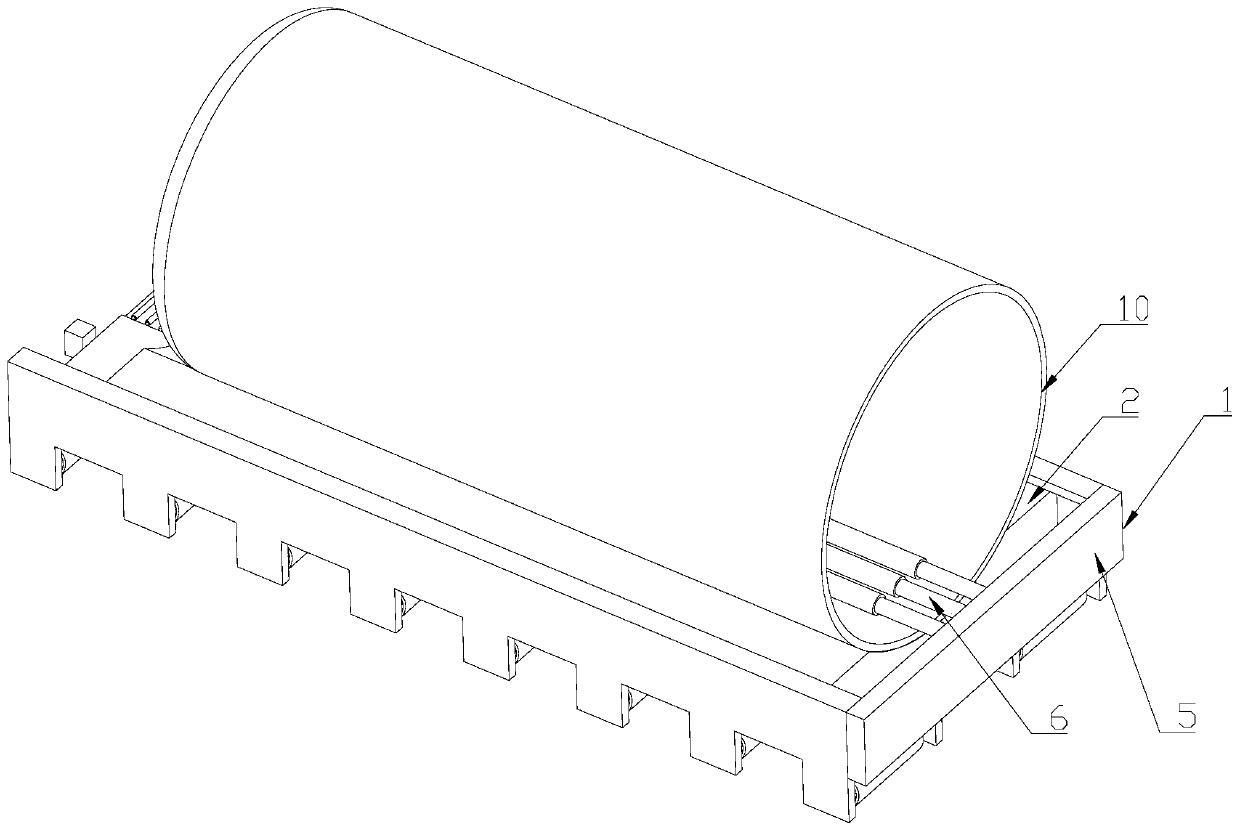

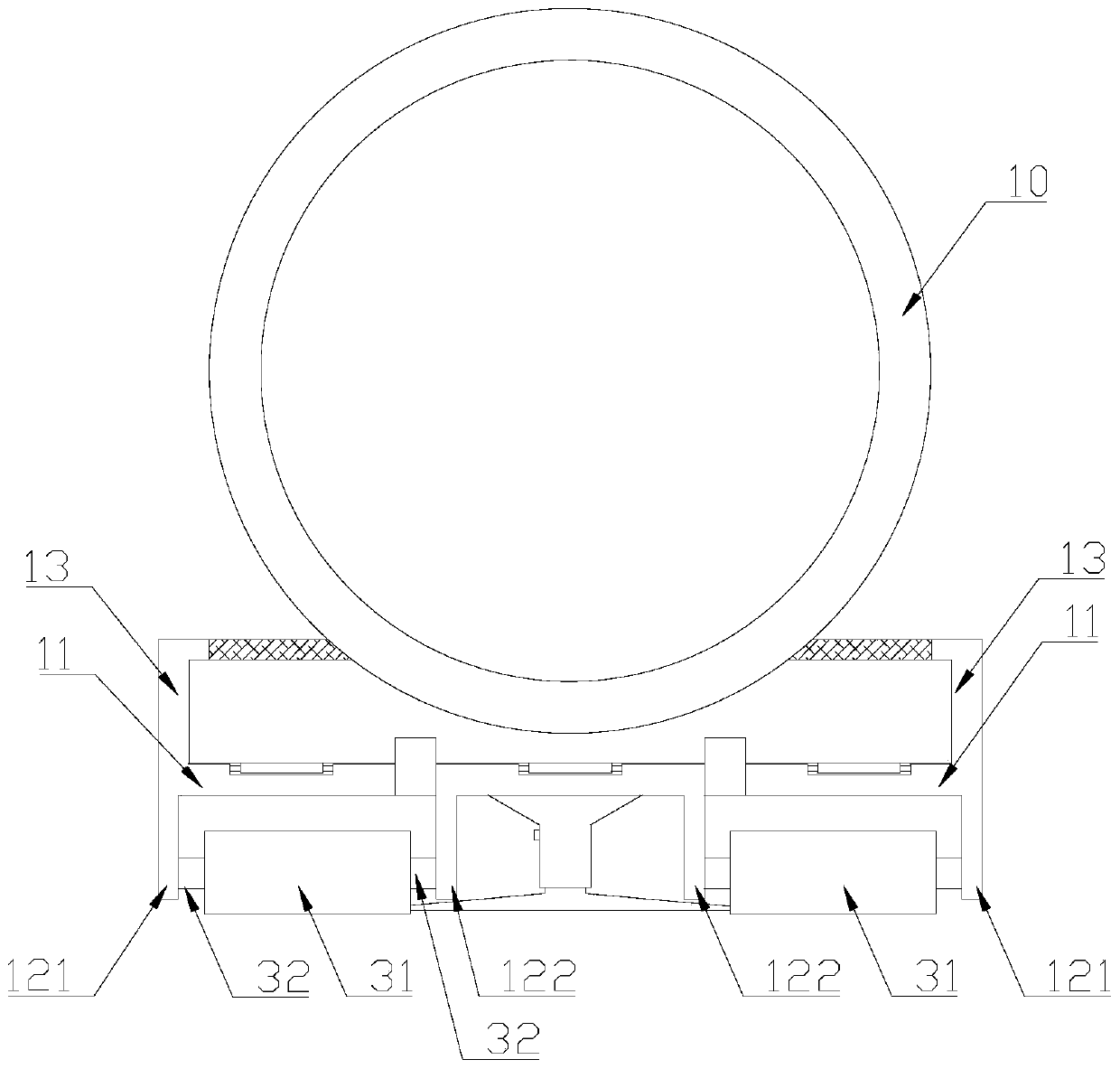

[0062] The technical solution adopted by the present invention is to combine Figure 1~2 As shown, a shield machine planar sliding propulsion device is provided, including a support frame 1, which is arranged on the upper side of the support frame 1, a seat plate 2 for supporting the shield machine 10, and a plurality of slides arranged on the lower side of the support frame 1. Shifting assembly 3 and a plurality of resistance increasing assemblies 4, and the reaction force device 5 that is arranged at the rear end of support frame 1, said shield machine 10 is provided with telescopic device 6 at one end, and said telescopic device (6) hydraulic push cylinder, said The hydraulic push cylinder provides thrust and pull for the shield machine. The hydraulic push cylinder 6 is supported by the reaction force device 5...

Embodiment 2

[0076] The present invention also provides a shield machine planar sliding propulsion method, using such as Figure 1-7 The propulsion device shown is realized; combined with Figure 8 As shown, the advancing method is:

[0077] When the telescopic device 6 is elongated and advanced, the resistance increasing assembly 4 is started to increase the resistance, so that the acceleration of the shield machine 10 relative to the seat plate 2 is greater than the acceleration of the support frame 1 relative to the ground;

[0078] When the telescopic device 6 shrinks, the resistance increasing assembly 4 is activated to reduce the resistance, so that the acceleration of the shield machine 10 relative to the seat plate 2 is smaller than the acceleration of the support frame 1 relative to the ground.

[0079] Specifically, the mass sum of the shield machine 10 and the expansion device 6 is M d , the mass of supporting frame 1 is M zc , the mass of seat plate 2 is M zb , the mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com