A planar sliding propulsion method of a shield machine

A shield machine and plane technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of low construction efficiency, bracket damage, and low reuse rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

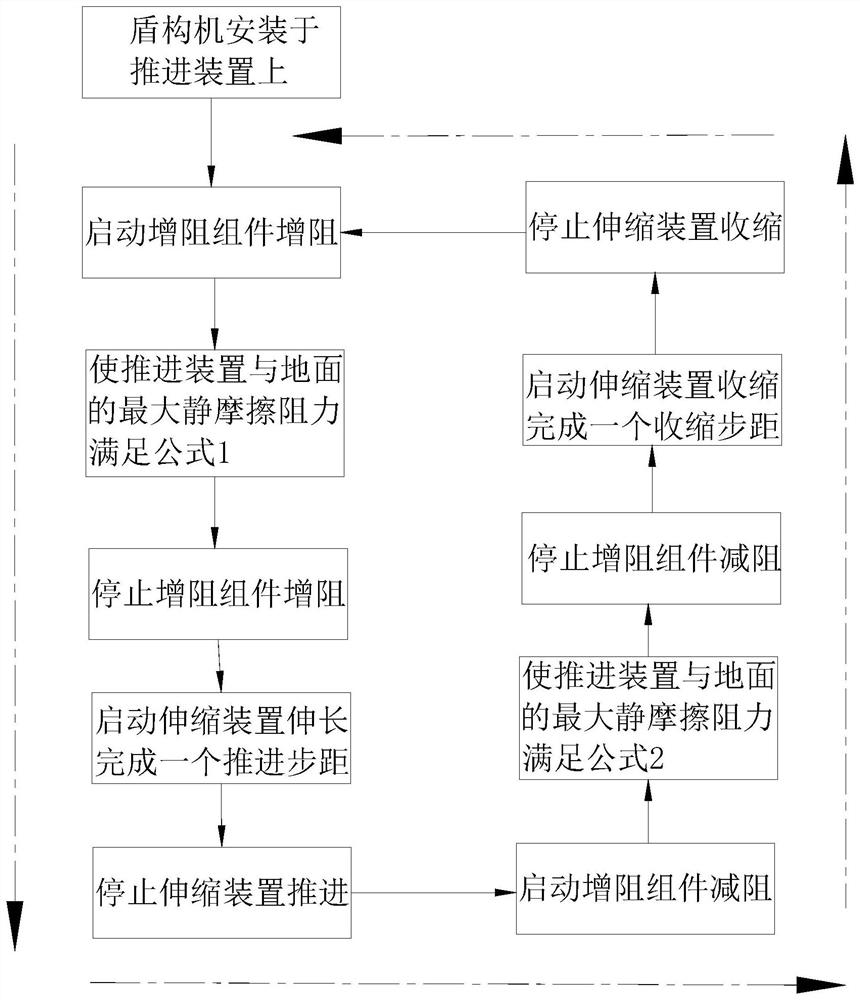

[0061] Such as figure 1 As shown, the present invention provides a planar sliding propulsion method of a shield machine, utilizing such as Figure 2-8 Shown propulsion device realizes; Described propulsion method is:

[0062] When the telescopic device 6 is elongated and advanced, the resistance increasing assembly 4 is started to increase the resistance, so that the acceleration of the shield machine 10 relative to the seat plate 2 is greater than the acceleration of the support frame 1 relative to the ground;

[0063] When the telescopic device 6 shrinks, the resistance increasing assembly 4 is activated to reduce the resistance, so that the acceleration of the shield machine 10 relative to the seat plate 2 is smaller than the acceleration of the support frame 1 relative to the ground.

[0064] Specifically, the mass sum of the shield machine 10 and the expansion device 6 is M d , the mass of supporting frame 1 is M zc , the mass of seat plate 2 is M zb , the mass of sli...

Embodiment 2

[0079] This embodiment also provides a planar sliding propulsion device for the shield machine, which can realize continuous propulsion and improve propulsion efficiency.

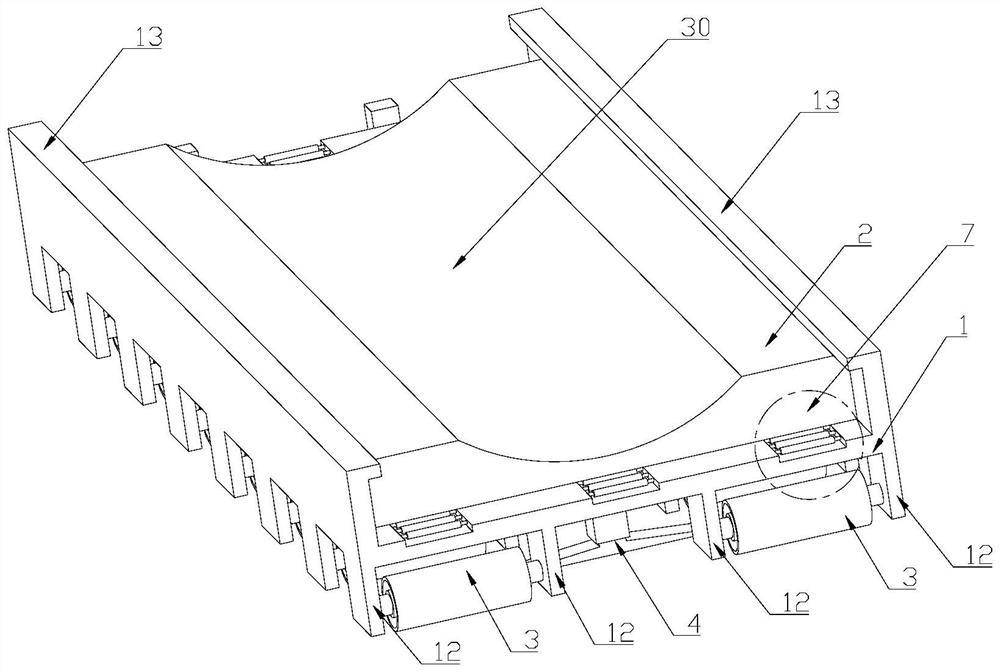

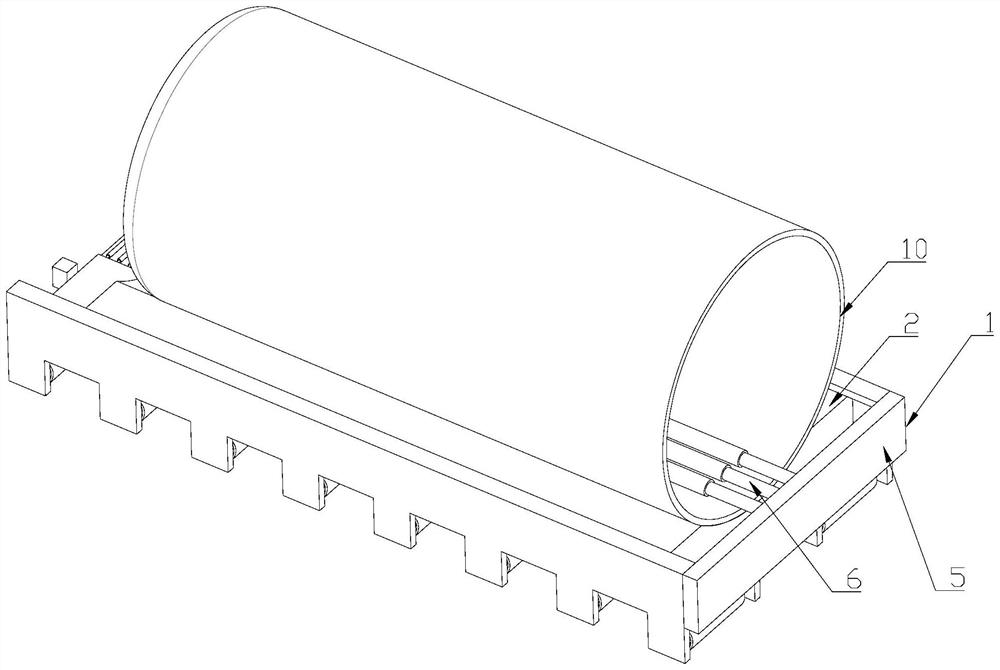

[0080] The technical solution adopted by the present invention is to combine Figure 2~3 As shown, a shield machine planar sliding propulsion device is provided, including a support frame 1, which is arranged on the upper side of the support frame 1, a seat plate 2 for supporting the shield machine 10, and a plurality of slides arranged on the lower side of the support frame 1. Shifting assembly 3, a plurality of resistance increasing assemblies 4, and a reaction force device 5 arranged at the tail end of the support frame 1, one end of the shield machine 10 is provided with a telescopic device 6, and the telescopic device 6 is a hydraulic push cylinder. The push cylinder provides thrust and pull for the shield machine. The hydraulic push cylinder 6 is supported by the reaction force device 5 to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com