Ring type steel corbel node for beam-free building cover connection reinforced concrete post

A technology of reinforced concrete column and beamless floor, applied in the direction of building, building structure, etc., can solve the problems of no more than 18 stories high, large vertical deflection, heavy foundation load, etc., to improve the bending and shearing capacity , the effect of reducing vertical displacement and increasing shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

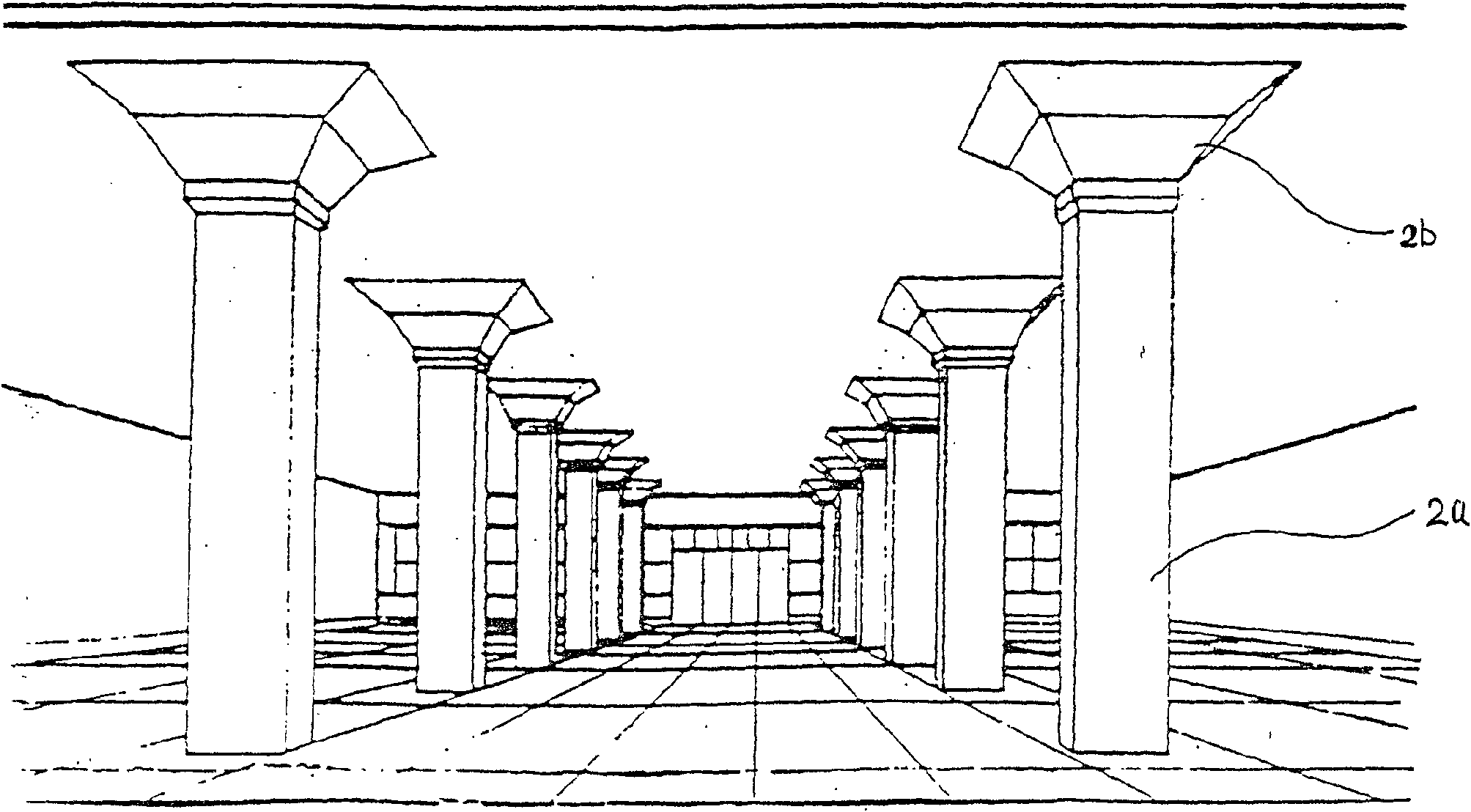

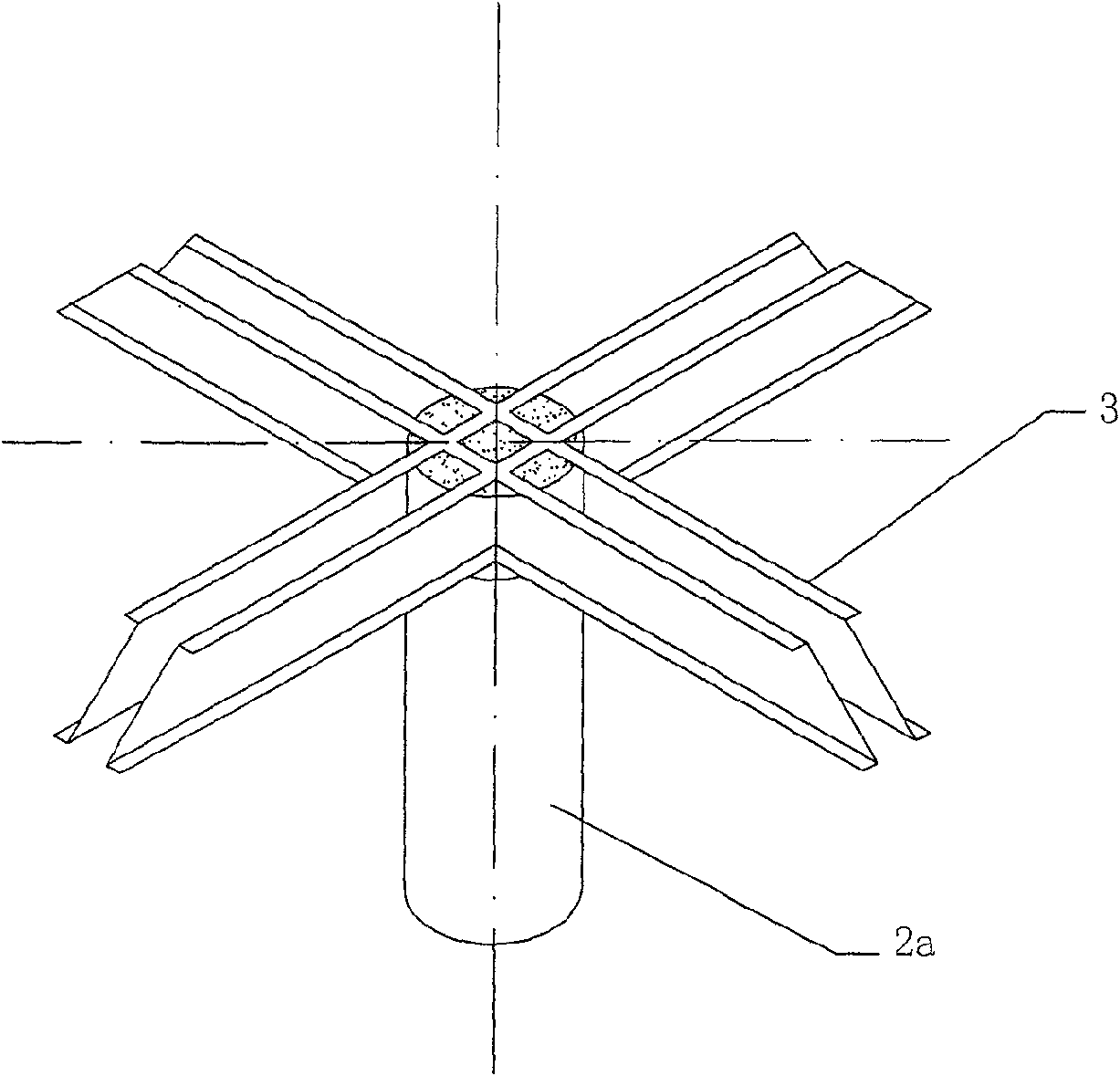

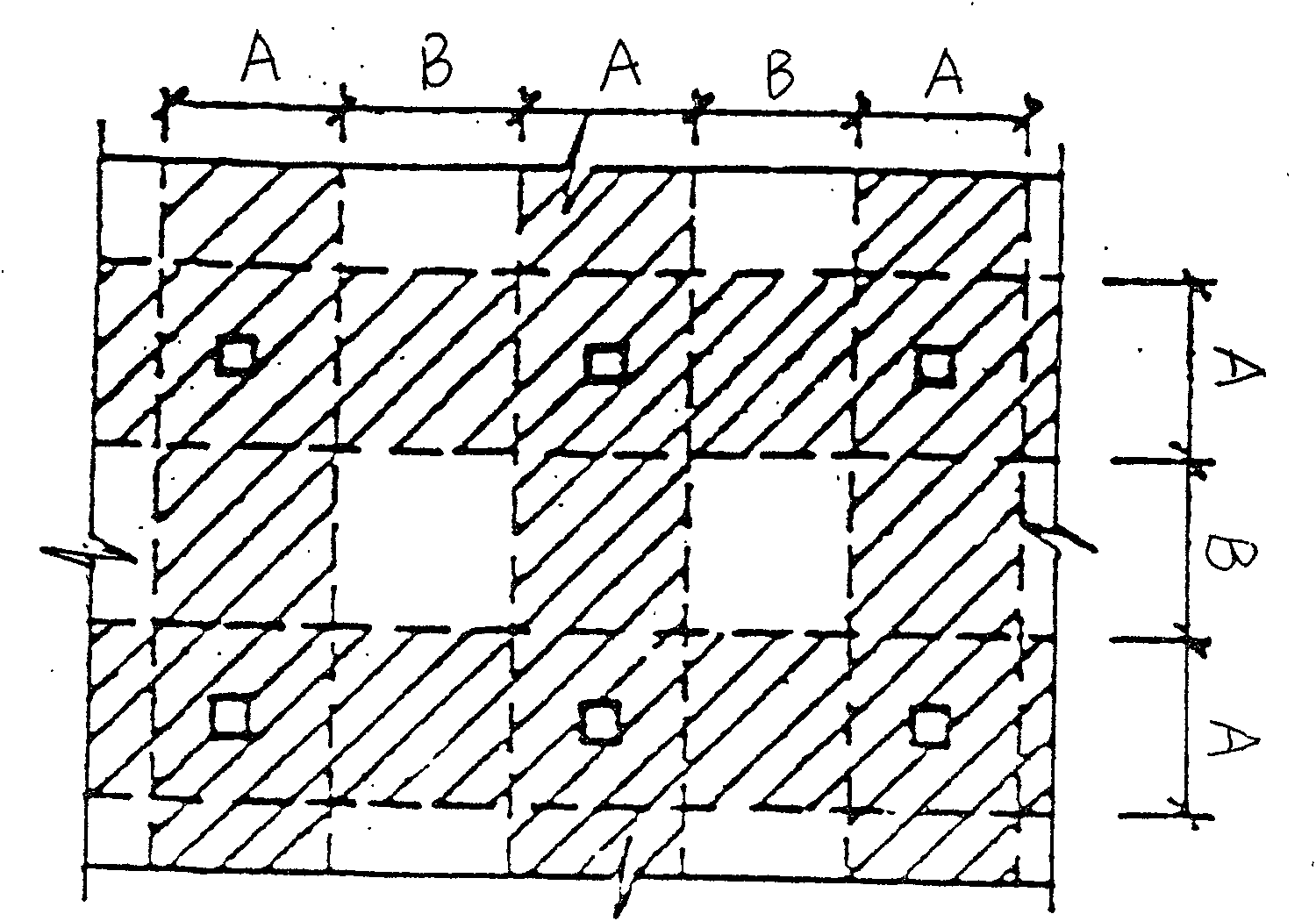

[0042] Figure 6-8 The shown ring-type steel corbel joint for the connection between the beamless floor and the reinforced concrete column is one of the specific embodiments of the present invention, including the reinforced concrete column 2 and the beamless floor 1 at the slab-column joint, And the steel corbel 3 that node place is provided with, there are four steel corbels 3, and the included angle between two steel corbels 3 adjacent to each other is 90 °. The four steel corbels 3 are non-piercing, and intersect to form a well-shaped structure, that is, the steel corbels 3 do not pass through the beamless floor 1, and the upper and lower parts of the beamless floor 1 are provided with criss-crossing Slab gluten 11, steel corbel 3 is provided with column longitudinal reinforcement 21 and column stirrup 22, because it is non-piercing type, column longitudinal reinforcement 21 bends outward along the horizontal direction when extending into beamless floor 1, and Be fixed on...

Embodiment 2

[0044] Figures 9 to 12 The shown ring-type steel corbel joint for the connection between beamless floor and reinforced concrete column is the second specific embodiment of the present invention. The difference from the previous embodiment is that the steel surrounding the reinforced concrete column 2 The number of rings is two circles, which are two inner and outer steel rings, wherein the steel ring on the inner side is tightly bound to the column, and the width of the lower ring plate 42a on the steel ring is greater than the width of the upper ring plate 41a; The radial widths of the upper and lower ring plates 41b, 42b on the steel ring are the same. The distance between two adjacent rings of steel rings is 1.5 to 2.5 times the height of the hidden beams of the floor.

Embodiment 3

[0046] Figure 13 , 14 The shown ring-type steel corbel joint for connecting beamless floors and reinforced concrete columns is the third specific embodiment of the present invention. The difference from the previous embodiment is that the steel corbel 3 is a through-core formula, that is, the steel corbel 3 passes through the beamless floor 1. Other structures are the same as in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com