Oriented steel fiber arrangement device and steel fiber concrete manufacturing method

A steel fiber concrete, directional arrangement technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of scattered distribution of steel fibers, uneven distribution of steel fibers, difficulty in concrete mixing, etc., to achieve easy realization, easy uniform distribution, The effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

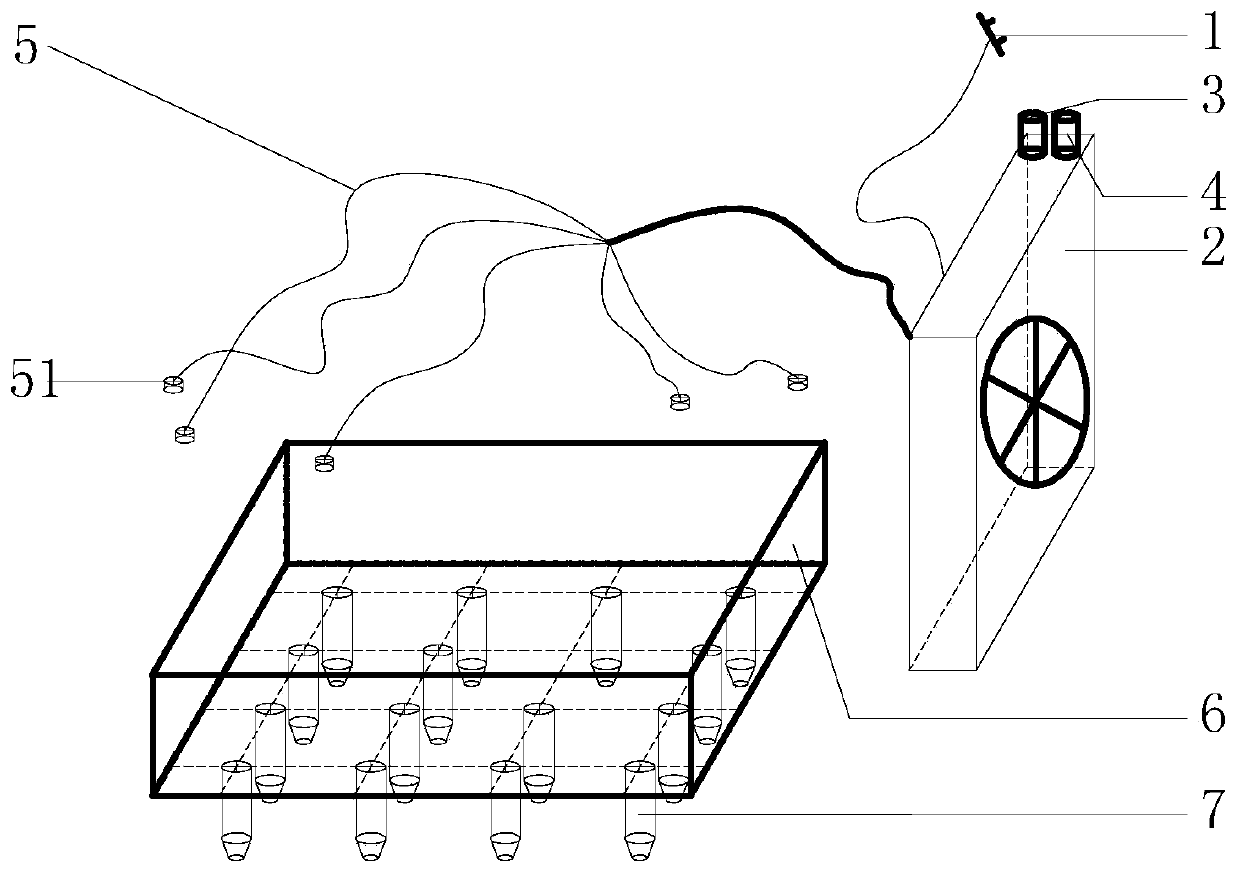

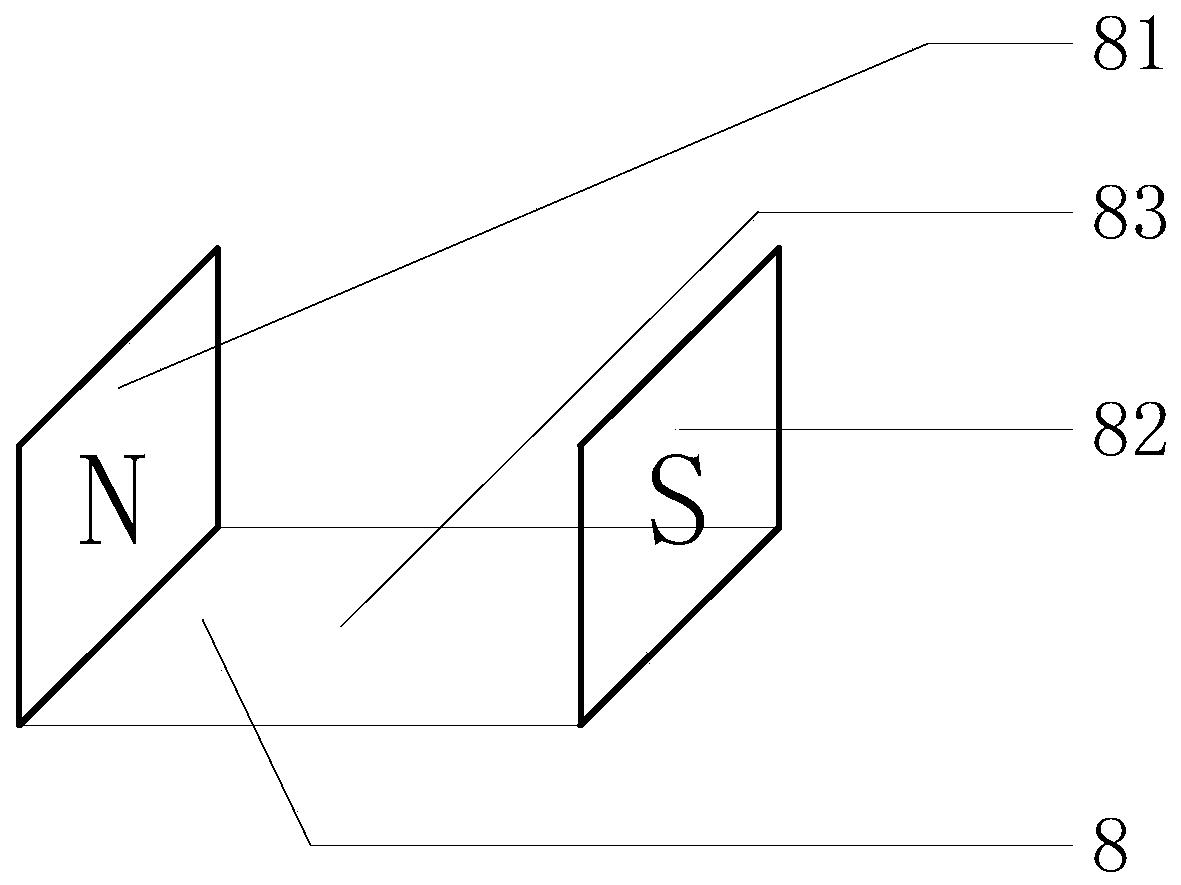

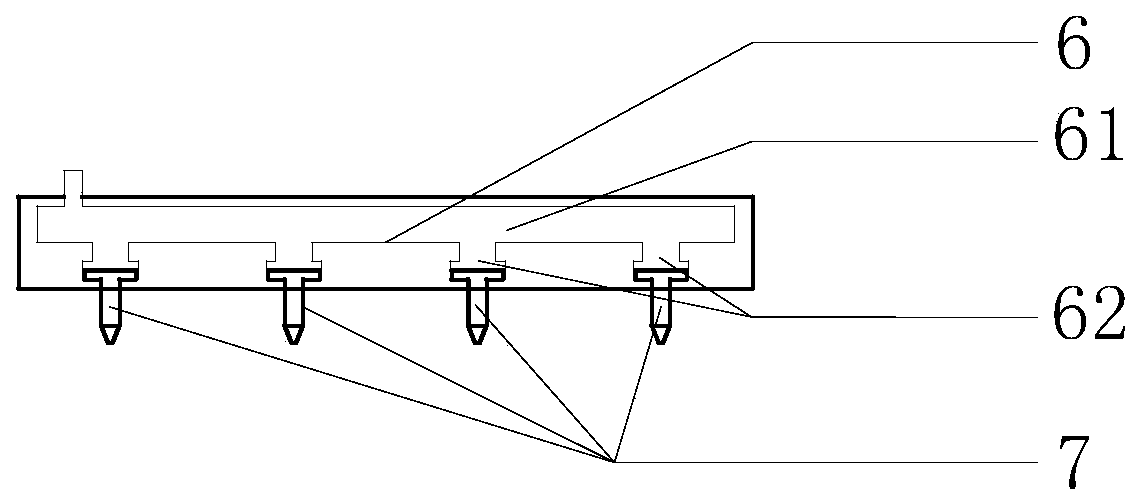

[0021] Such as figure 1 As shown, a steel fiber directional arrangement device includes a power supply 1, a blower 2, an adsorption switch 3, a suction switch 4, an air pipe 5, a steel fiber adsorption disc 6, an adsorption needle 7, and a directional magnetic field belt 8; the blower 2 passes through the air pipe 5 is connected with the steel fiber adsorption disk 6, the adsorption needle 7 is located below the surface of the steel fiber adsorption disk 6, when the adsorption switch 3 is turned on, the adsorption needle 7 absorbs the steel fibers; the adsorption needle 7 can rotate in the steel fiber adsorption disk 6; Open the suction switch 4, the suction needle 7 is fixed on the steel fiber suction disk 6 by suction, and cannot rotate. The orientation magnetic field generated by the orientation magnetic field belt 8 can be used for steel fiber orientation.

[0022] Such as figure 1 As shown, one end of the air pipe 5 is connected to the blower 2, and the other end includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com