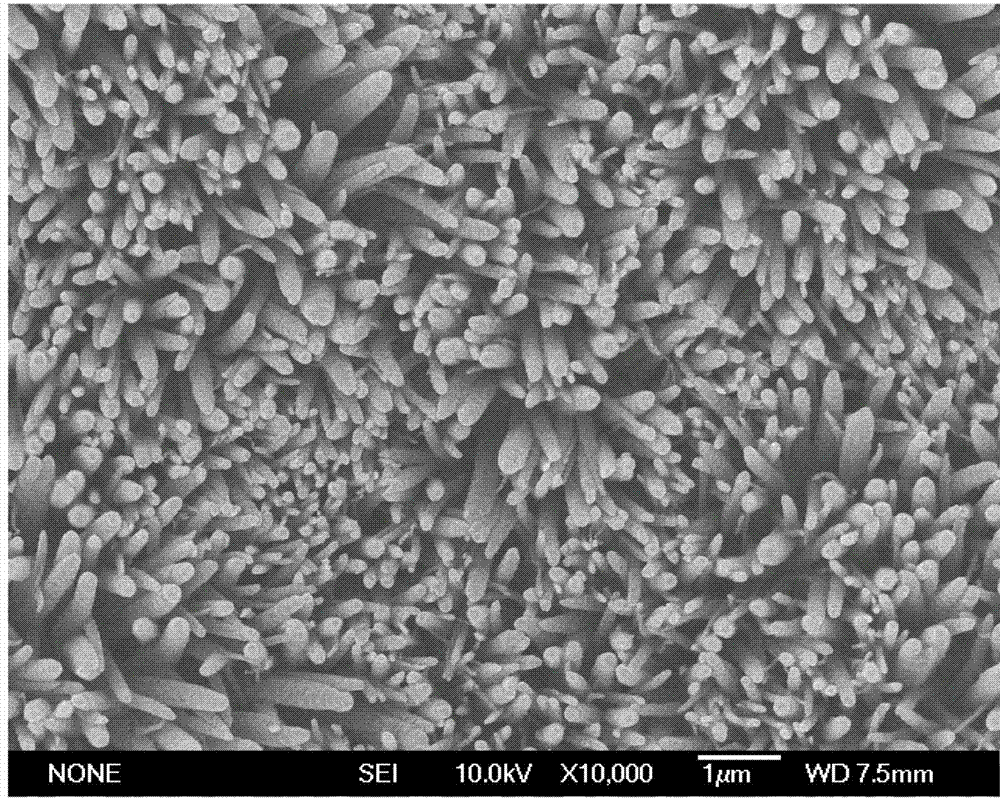

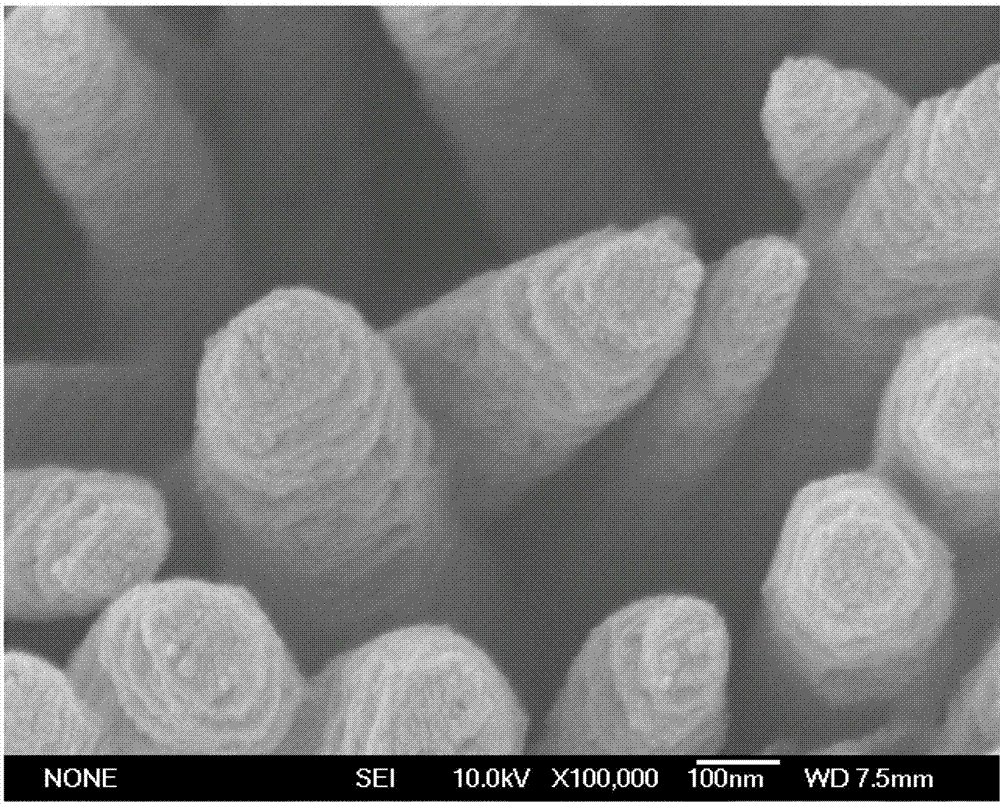

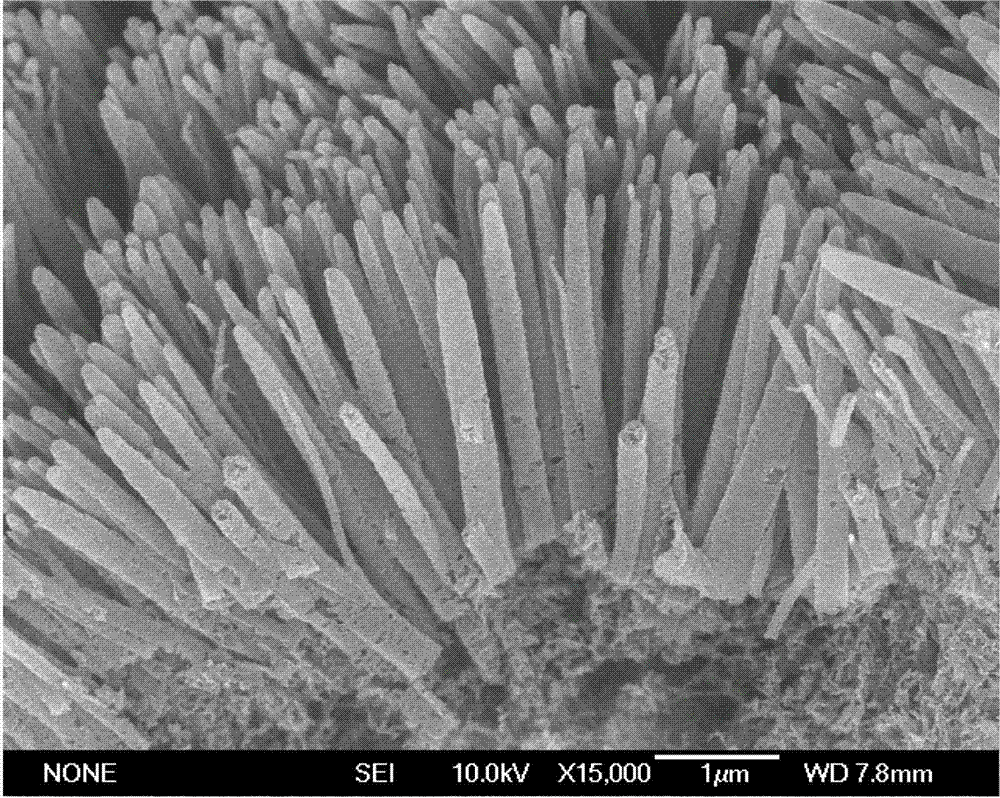

Porous carbon nanorod array electrode and preparation method thereof

A nanorod array and array electrode technology, applied in the field of carbon nanorod array electrodes and their preparation, can solve the problems of low conductivity, easy agglomeration, easy winding and the like, and achieve the effects of large specific surface area, high application value and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Weigh 0.5g of zinc nitrate and dissolve it in 50mL of deionized water. After fully dissolving, add 1.78g of ammonia water dropwise under the action of magnetic stirring, pour the reaction solution into a polytetrafluoroethylene liner, and put a piece of 2cm×4cm Titanium sheet, after being sealed with a stainless steel jacket, keep warm in an oven at 70°C for 1000 minutes;

[0032] 2. Take out the titanium sheet, rinse it with deionized water and absolute ethanol, put the titanium sheet grown with the zinc oxide nanowire array precursor into a horizontal quartz tube to heat, the nitrogen flow rate is 100 sccm, the pressure is atmospheric pressure, use 96 The temperature was raised to 500°C in 1 minute, and then annealed for 0.5 hours while maintaining the temperature of 500°C and the nitrogen flow rate;

[0033] 3. Keep the nitrogen flow rate constant and continue to raise the temperature. The heating rate is 10°C / min. When it rises to 750°C, hydrogen gas is introduce...

Embodiment 2

[0039] 1. Weigh 0.5g of zinc nitrate and dissolve it in 50mL of deionized water. After fully dissolving, add 1.78g of ammonia water dropwise under the action of magnetic stirring, pour the reaction solution into a polytetrafluoroethylene liner, and put a piece of 2cm×4cm Titanium sheet, after being sealed with a stainless steel jacket, keep warm in an oven at 70°C for 800 minutes;

[0040]2. Take out the titanium sheet, rinse it with deionized water and absolute ethanol, put the titanium sheet grown with the zinc oxide nanowire array precursor into a horizontal quartz tube to heat, the nitrogen flow rate is 80 sccm, the pressure is atmospheric pressure, use 96 The temperature was raised to 500°C in 1 minute, and then annealed for 0.5 hours while maintaining the temperature of 500°C and the nitrogen flow rate;

[0041] 3. Keep the nitrogen flow rate constant and continue to raise the temperature at a rate of 10°C / min to 720°C. Introduce hydrogen with a hydrogen flow rate of 40...

Embodiment 3

[0043] 1. Weigh 0.5g of zinc nitrate and dissolve it in 50mL of deionized water. After fully dissolving, drop 2.225g of ammonia water under the action of magnetic stirring, pour the reaction solution into a polytetrafluoroethylene liner, and put a piece of 2cm×4cm Titanium sheet, after being sealed with a stainless steel jacket, keep warm in an oven at 70°C for 1000 minutes;

[0044] 2. Take out the titanium sheet, rinse it with deionized water and absolute ethanol and dry it; put the titanium sheet grown with the zinc oxide nanowire array precursor into a horizontal quartz tube to heat, the nitrogen flow rate is 100 sccm, and the pressure is atmospheric pressure , it takes 86 minutes to raise the temperature to 450°C, and then keep the temperature of 450°C and the nitrogen flow rate constant for annealing for 0.5 hours;

[0045] 3. Keep the nitrogen flow rate constant and continue to raise the temperature. The heating rate is 10°C / min. When it rises to 700°C, hydrogen gas is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com