Dimension reduction low profile rear cavity line polarization antenna

A low-profile, linearly polarized technology, applied in the microwave field, can solve the problems of high processing cost and large volume, and achieve the effects of reduced production cost, reduced size, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

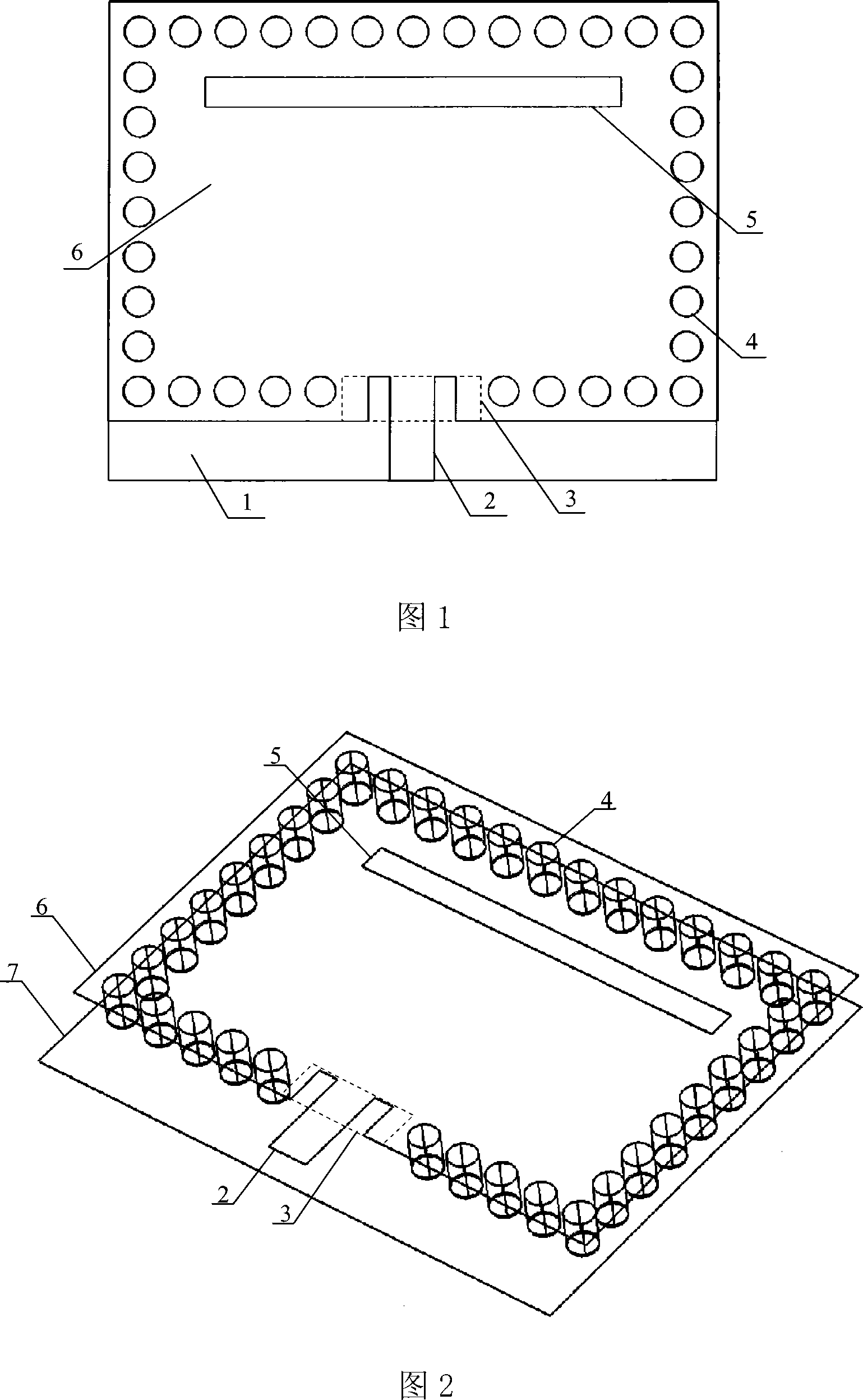

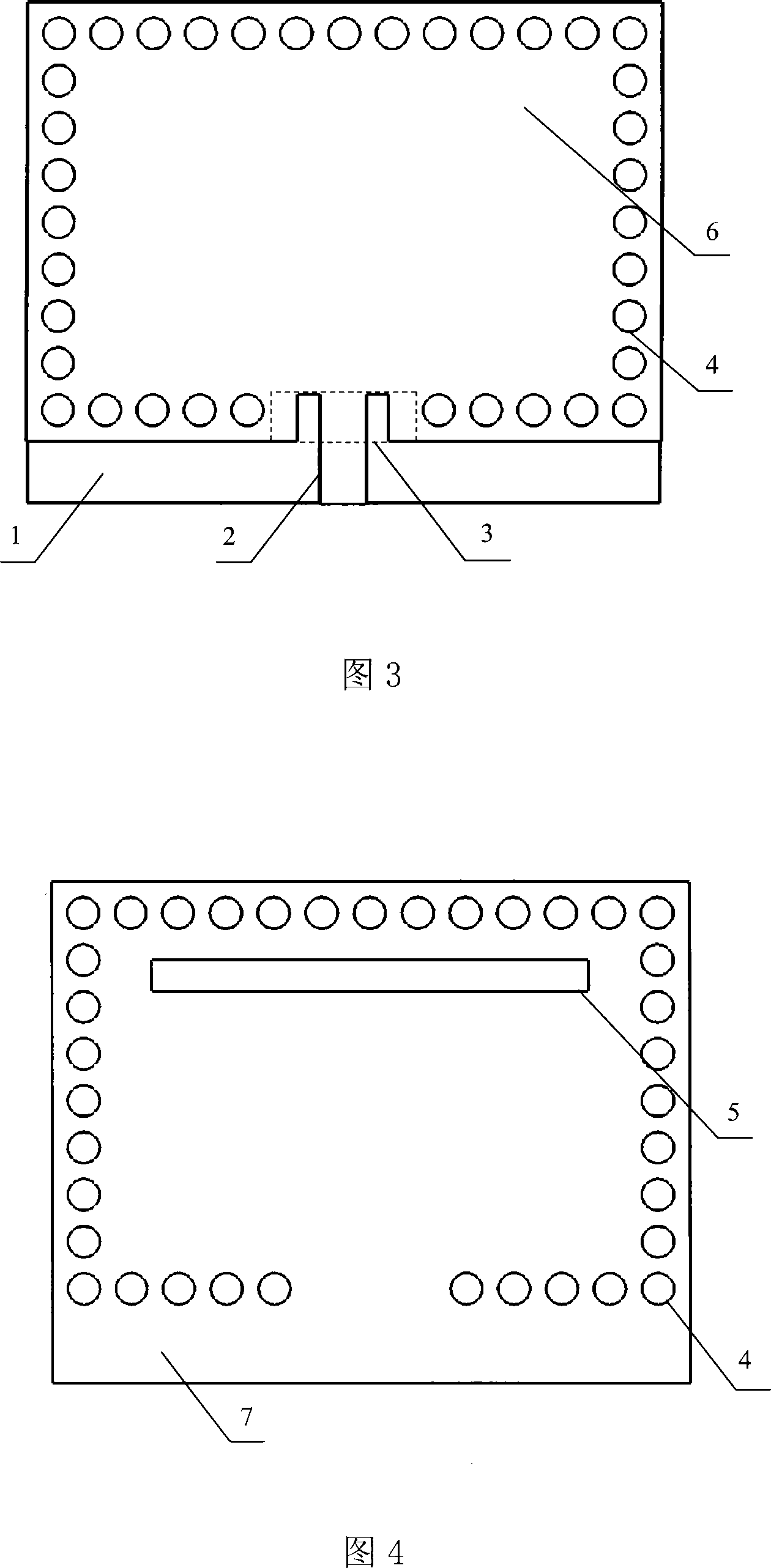

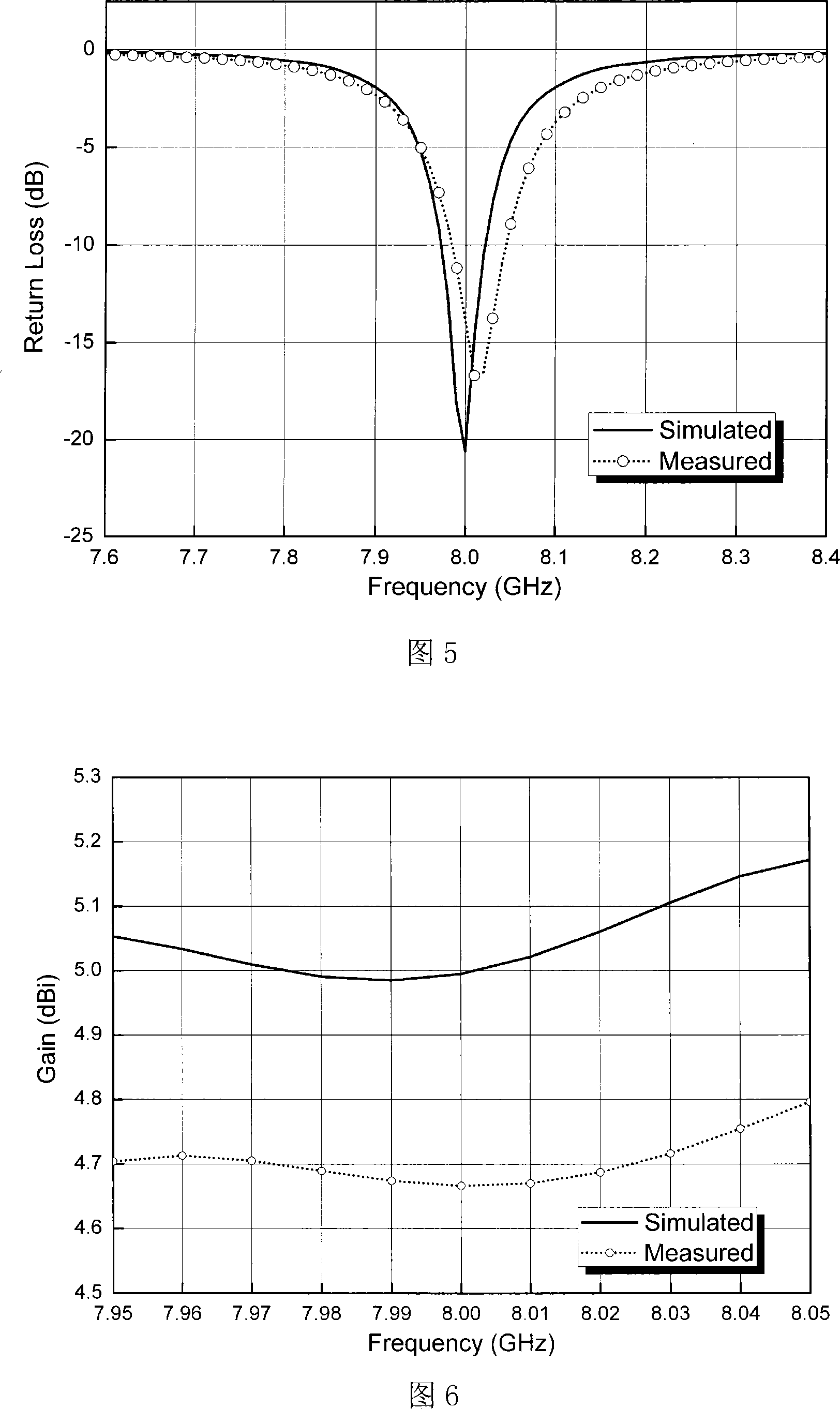

[0021] As shown in Figures 1 and 2, the cavity-backed linear polarization antenna with a reduced size and low profile includes a Rogers5880 dielectric substrate 1 with a thickness of 0.5 mm. The two sides of the dielectric substrate 1 are coated with metal layers, which are the upper metal layer 6 and the lower metal layer respectively. Layer 7, wherein the lower metal layer 7 serves as the formation. As shown in Figure 3, the upper metal layer 6 is etched with a microstrip line 2 for feeding and a coplanar waveguide transmission line 3 (included in the dotted line frame). The coplanar waveguide transmission line 3 is a common ground coplanar waveguide structure, and its middle metal strip The external extension is used as the microstrip line 2. The length and width of the microstrip line 2 are 4 mm and 1.45 mm respectively, and the two air gaps of the coplanar waveguide transmission line 3 both have a width of 0.7 mm and a length of 1.5 mm. A through hole with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com