Device and method for testing volume deformation of organic phase-change heat storage material

A technology of phase change heat storage materials and heat storage materials, which is applied in the field of testing devices for volume deformation of organic phase change heat storage materials, and can solve problems such as poor repeatability and low test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

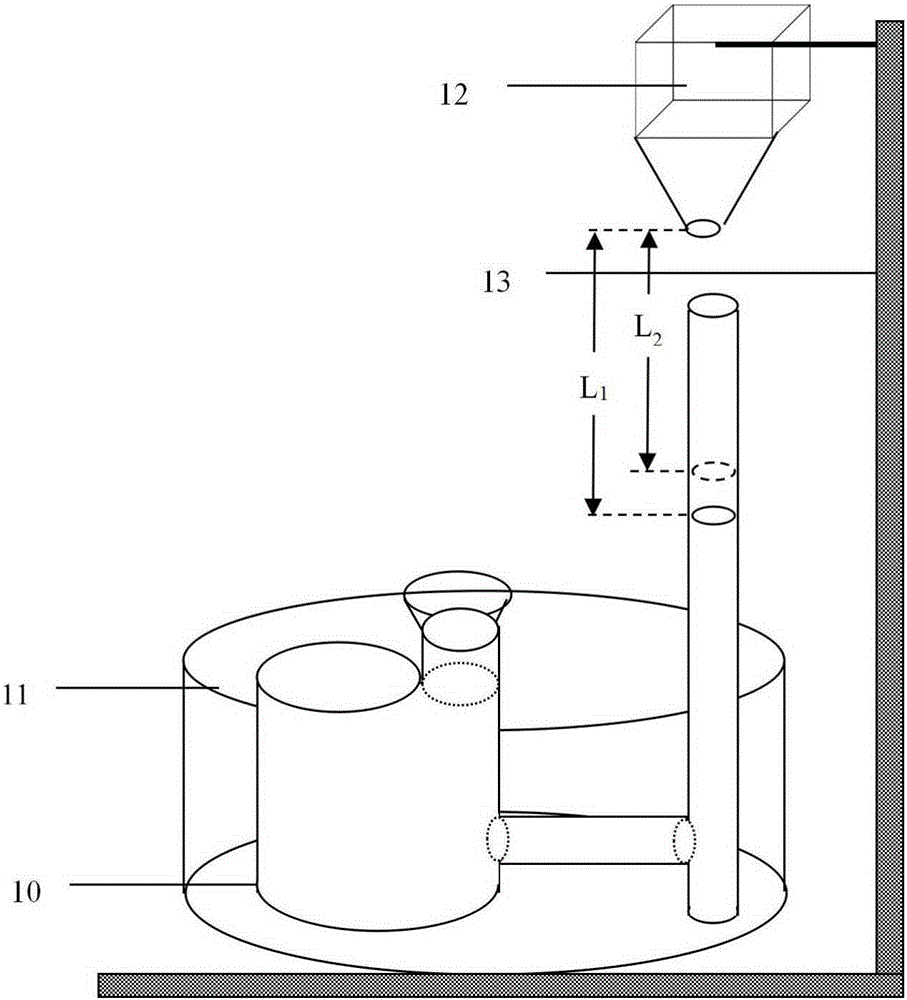

[0017] Embodiment 1: In this embodiment, it includes a communication container 10, a water bath heating device 11, a fixed bracket 13 and a laser displacement sensor 12;

[0018] The laser displacement sensor 12 is fixed on a fixed bracket 13, and the communicating container 10 is arranged inside the water bath heating device 11;

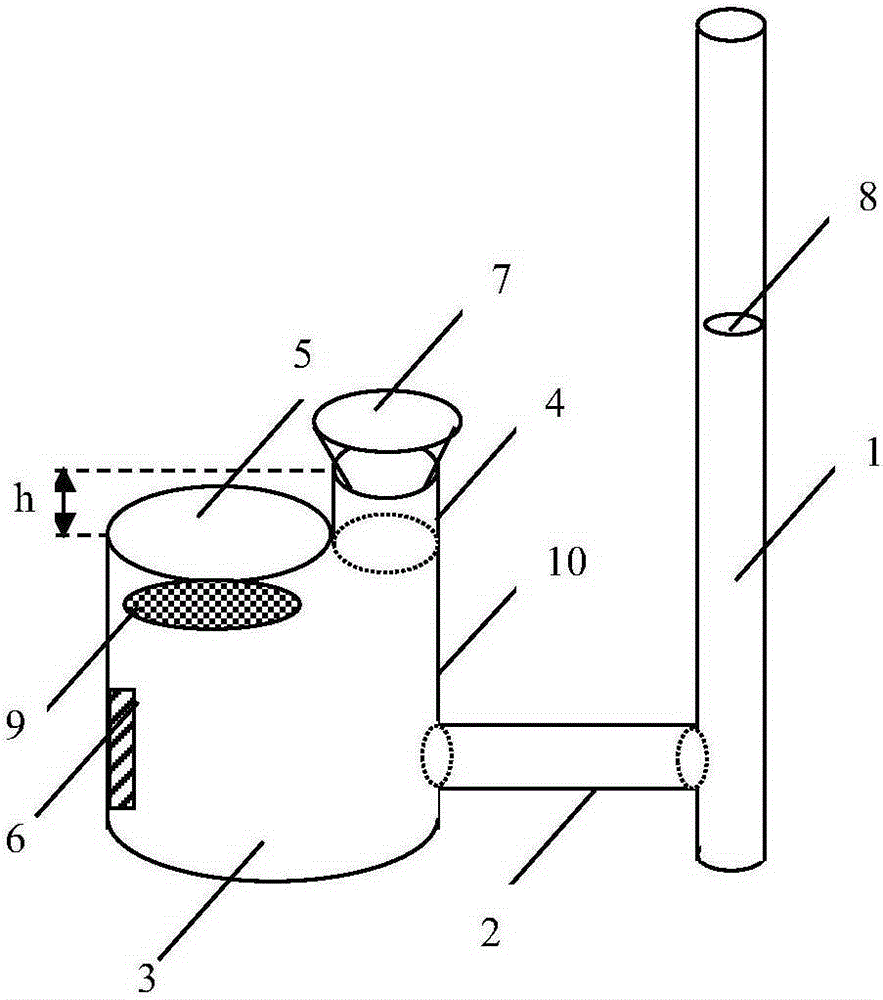

[0019] Wherein, the communication container 10 includes an upright round thin tube 1, a horizontally arranged bottom connecting thin tube 2, an upright round thick tube 3, an open thin tube 4, a sealing cover 5, a temperature sensor 6, a rubber plug 7, Plastic sheet 8 and gauze 9;

[0020] The thin round tube 1 and the thick round tube 3 communicate with each other through the thin tube 2 at the bottom; the top of the thick round tube 3 has two holes, wherein one hole is sealed with a sealing cover 5, and the other is sealed with a sealing cover 5. The hole is connected with an open thin tube 4, and the open thin tube 4 is sealed with a rubber stop...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: the diameter of the thin open tube 4 is smaller than the diameter of the round thick tube 3 .

[0025] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the height of the thin open tube 4 is 30-50 mm higher than that of the sealing cover 5 .

[0027] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com