Rotary type ultraphonic motor

An ultrasonic motor, rotary technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. It is difficult to realize the problems of high torque and low working reliability, so as to achieve the effect of simple structure, consistent performance and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

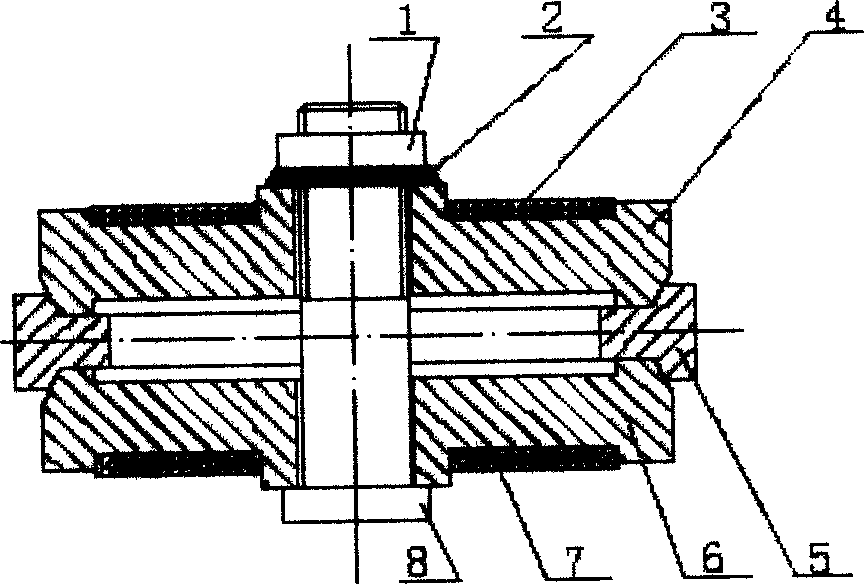

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

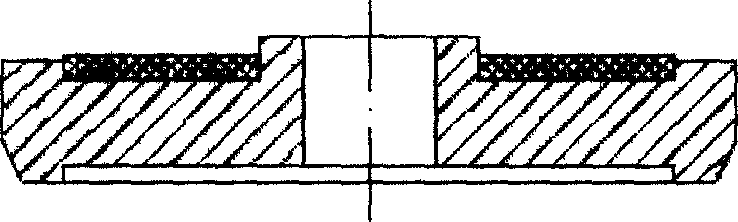

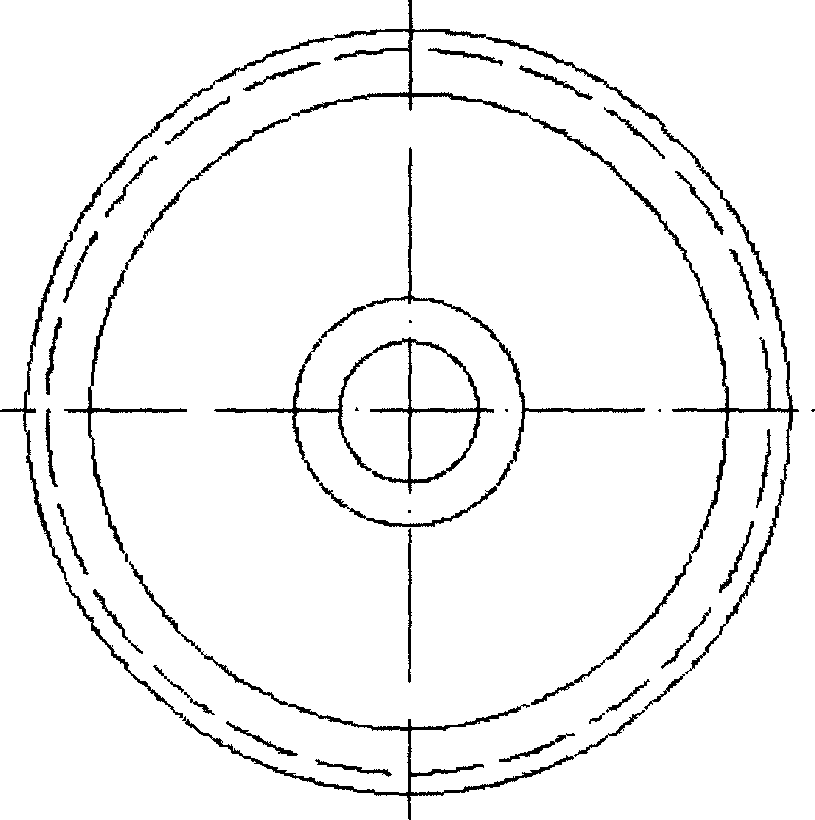

[0023] Structural schematic diagram of the present invention is attached image 3 , attached Figure 4 As shown, it includes an upper disc-shaped piezoelectric ceramic sheet 3, a lower disc-shaped piezoelectric ceramic sheet 7, an upper thin round metal elastic body 4, a lower thin round metal elastic body 6, a ring-shaped rotor 5, and a fastening nut 1 , disc spring 2, fastening bolt 8, the disc-shaped piezoelectric ceramic sheets 3, 7 are respectively pasted with the thin circular frustum-shaped metal elastic body 4, 6 through epoxy resin to form two composite vibrators of the thin circular frustum body, The inner ring surface of the ring-shaped rotor 5 is coaxial, and the upper bottom surface is adjacent to two identical truncated cones, which are matched with the circular truncated surfaces of the thin truncated metal elastomers 4 and 6, and the pre-tightening for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com