Detecting device and detecting method for surface evenness of gate

A surface smoothness and detection device technology, applied in the field of measurement, can solve the problems of unsuitable detection of gate water level fluctuation areas, different ultrasonic propagation speeds, and influence on detection results, etc., to achieve high adaptability, high degree of mechanical automation, and data observation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

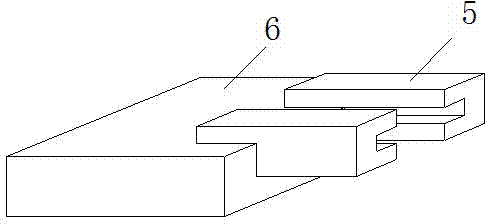

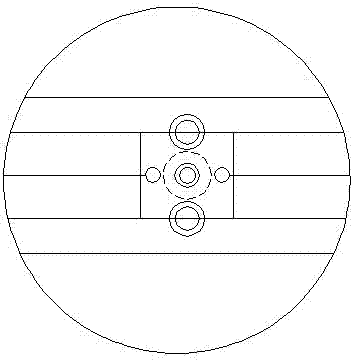

[0032] figure 1 It is a schematic diagram of the overall structure of the present invention, Figure 4 yes figure 1 Partial enlarged view of C in the figure, it can be seen from the figure that the detection device for the surface flatness of the gate 8 is installed on the upstream surface of the gate 8, and the detection device includes a horizontal track 9, an elastic pressure-sensitive box 10, a data instrument 1 and Two longitudinal slides 7, the data instrument 1 is arranged vertically above the gate 8, the two longitudinal slides 7 are symmetrically arranged on both sides of the upstream surface of the gate 8, and both longitudinal slides 7 are arranged There is a moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com