Measuring device and method for apparent fluffing and balling as well as abrasion loss of yarn

A technology for measuring devices and wear amount, which is applied in textile testing, material inspection products, etc., and can solve the problems of long friction time, large error, and time-consuming occupation of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

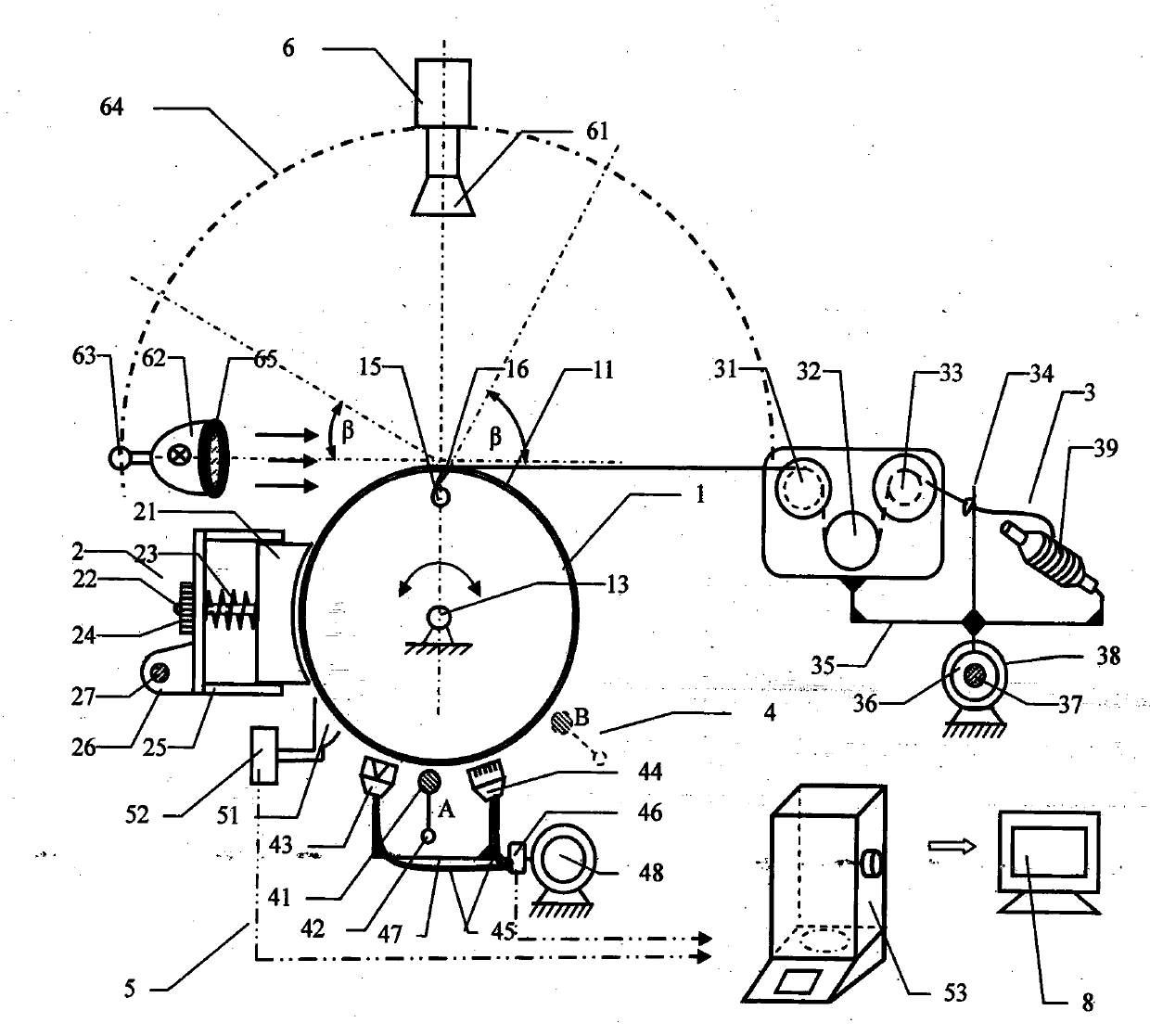

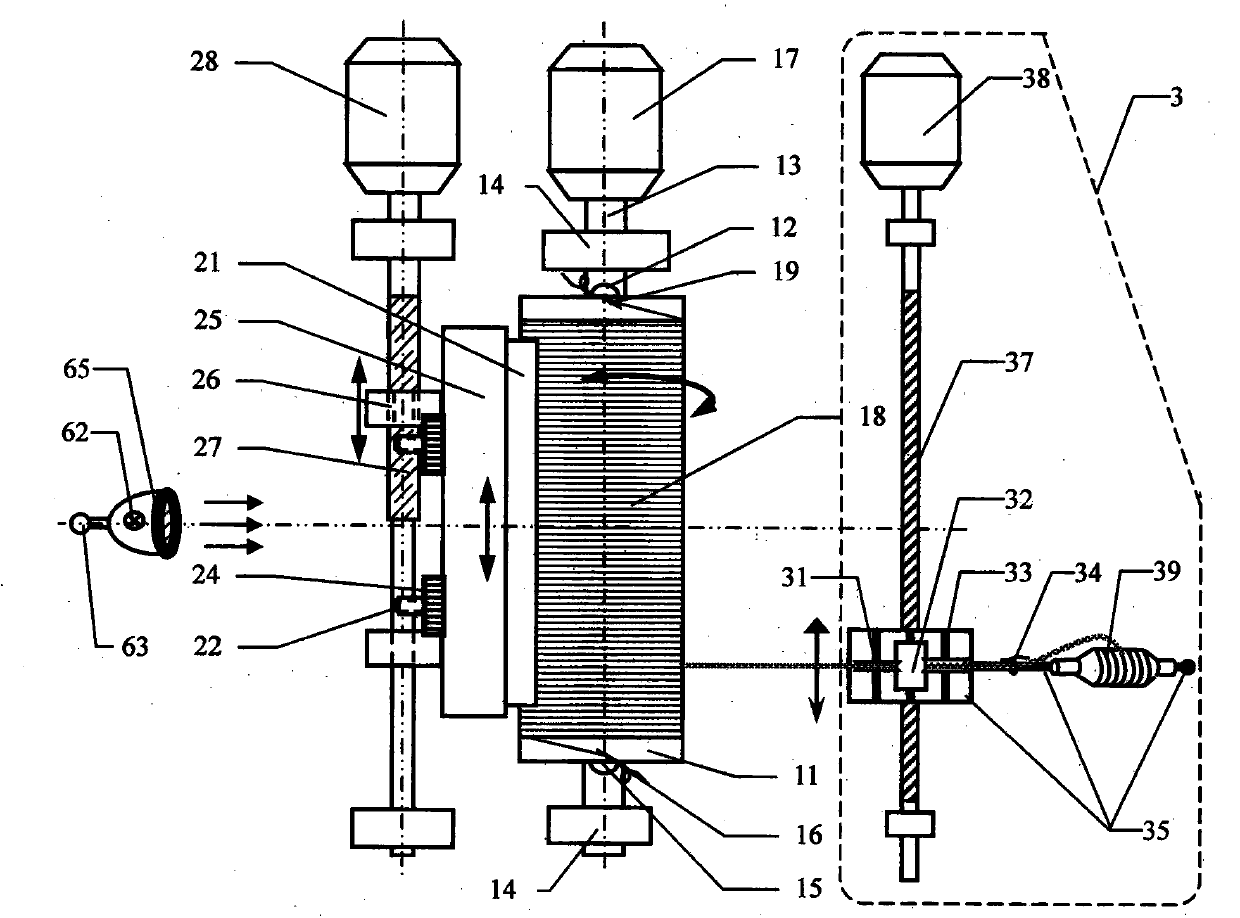

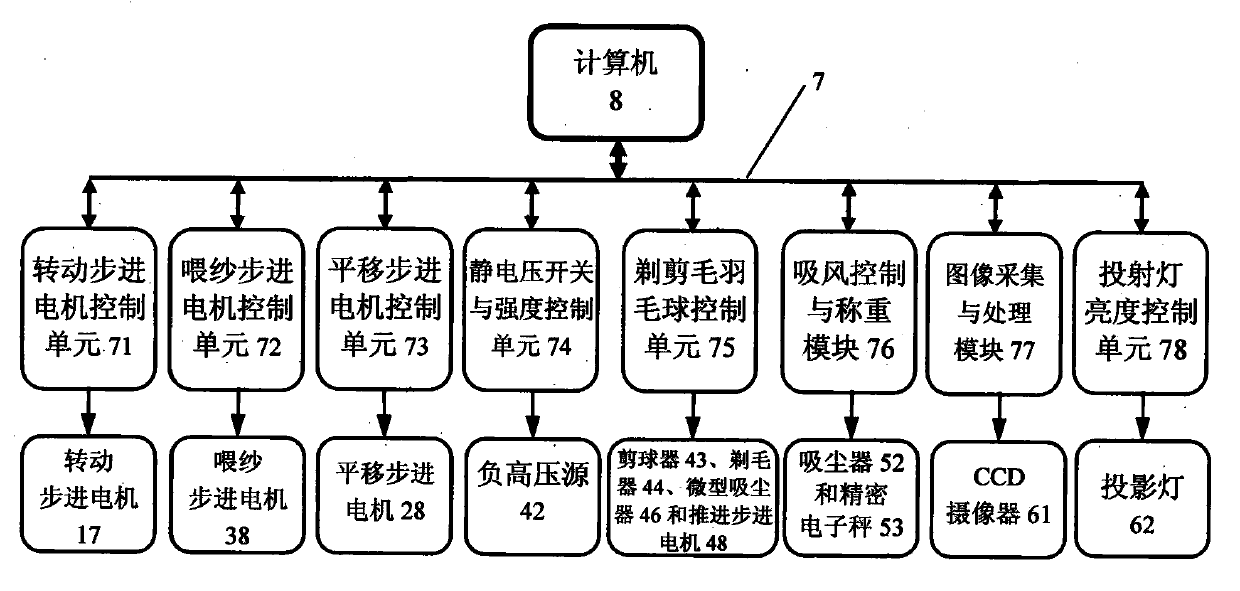

[0127] Adopt measuring device and method of the present invention, see Figure 1~3 . A complete set of measurement from the first step to the third step is performed on the fluffing and pilling of the full wool 2×8.2tex double-ply yarn with a yarn number of 16.4tex, which is symmetrically rotated by the Lissajous curve friction Measurement condition parameter and actual measurement result see the process measurement curve of the following table embodiment 1 column and described second step, see Figure 4 . From the measured results, it can be seen that on the bobbin 11, the fluffing of the final state grinding yarn sample of the full-hair strand yarn is more obvious, and the average length of the hairiness is 5.2mm and the hairiness density is 0.139; while the average length of the hairiness of the full-hair strand yarn sample is 1.1mm and dense The degree of fluffing is 0.001, which is normal and there is no fluffing phenomenon. Compared with the ground yarn sample, the flu...

Embodiment 2

[0129] Adopt measuring device and method of the present invention, see Figure 1~3 . The pilling of the wool and acrylic blended yarn with a yarn number of 13.ltex is asymmetrically rotated by the Lissajous curve friction and is the first yarn sample of the first step and the process measurement of the second step. Calculate, its measurement condition parameter and actual measurement result are shown in the process measurement curve of the following table embodiment 2 columns and the second step, see Figure 5 . As can be seen from the actual measurement results, the wool acrylic blended yarn final state grinding yarn sample fluffing is remarkable on the yarn bobbin 11, and the hairiness average length 8.0mm and hairiness density are 0.167; The density is 0.0012, which is normal, and there is basically no fuzzing phenomenon. Compared with the ground yarn sample, the fluff of the wool-acrylonitrile blended yarn is significant, and the final state hairiness significance is 3....

Embodiment 3

[0131] Adopt measuring device and method of the present invention, see Figure 1~3 . The fluffing and pilling of the polyester-cotton blended yarn whose yarn number is 18.3tex is used as a separate symmetrical rotational friction and is the measurement and calculation of the first step initial yarn sample and the third step final state friction sample. The measurement condition parameters and the actual measurement results are shown in the Example 3 column of the following table. As can be seen from the actual measurement results, the polyester-cotton blended yarn final state grinding sample fluffing is remarkable on the bobbin 11, and the hairiness average length 8.6mm and hairiness density are 0.108; The density is 0.0007, which is normal without fuzzing. Compared with the first yarn sample and the ground yarn sample, the fluff of the polyester-cotton blended yarn is significant, and the final state hairiness significance is 4.67. The final grinding sample of the polyeste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com