Honeycomb core surface shape measuring device

A technology for measuring devices and honeycomb cores, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of not being able to obtain the specific surface shape of the honeycomb core material, and achieve the effects of obtaining rich information, reducing use costs, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

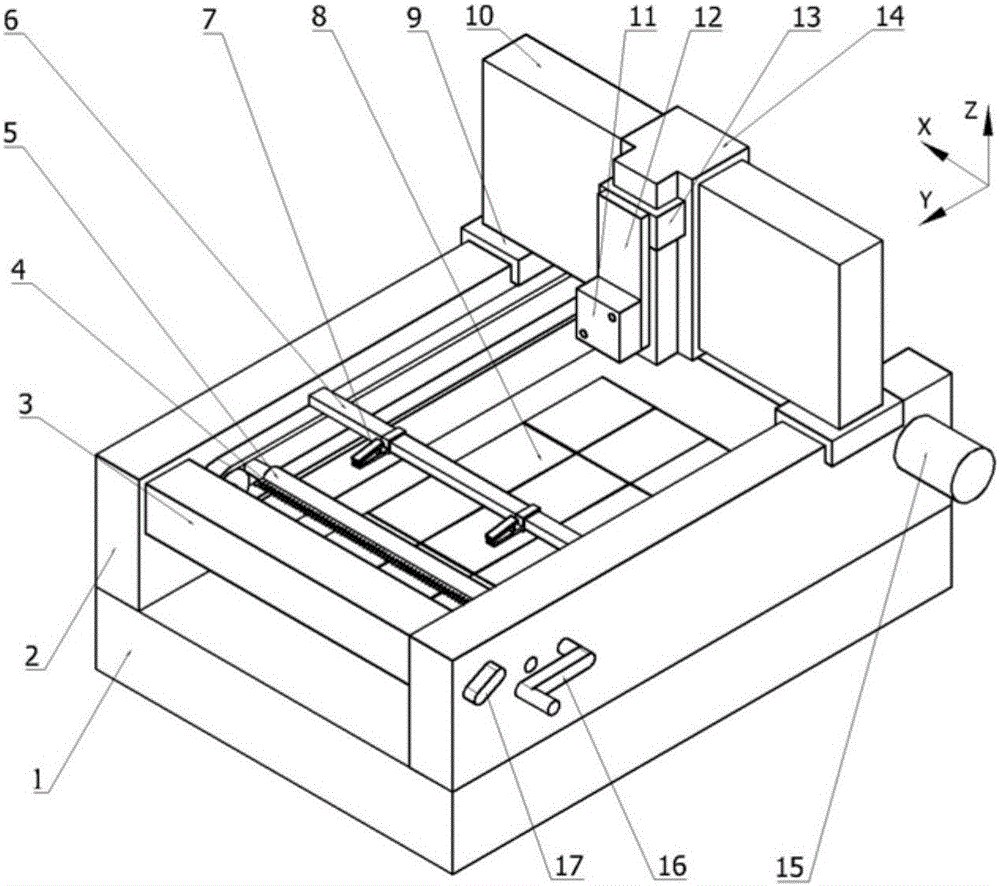

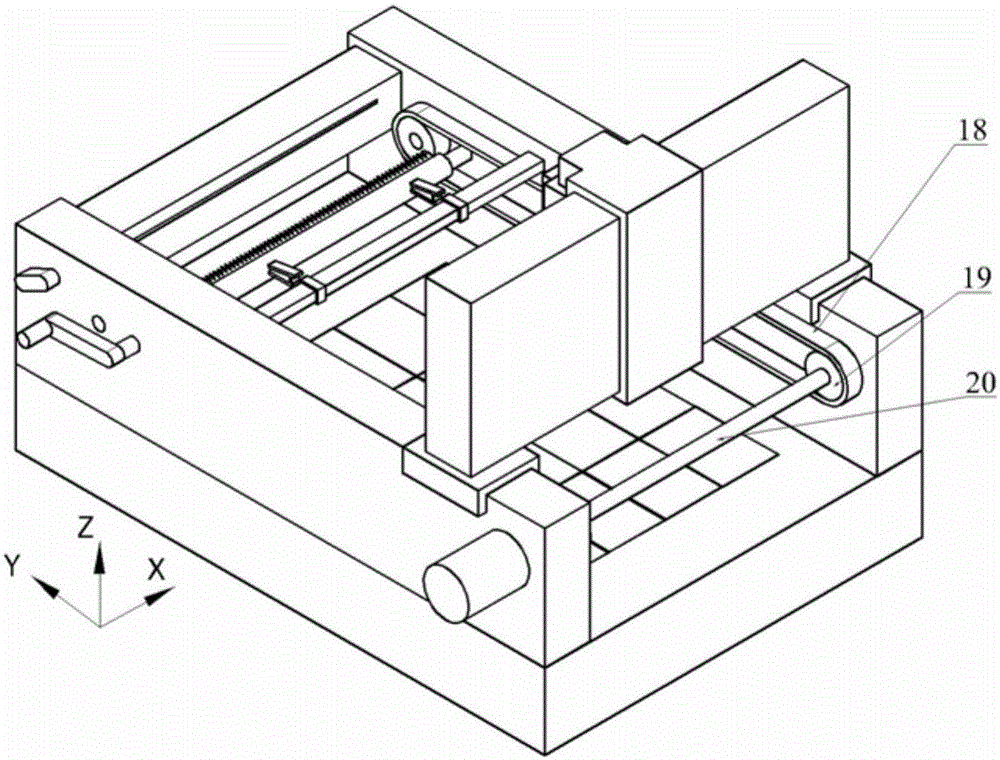

[0064] Such as Figure 1-Figure 5 As shown, a honeycomb core surface shape measurement device includes: a laser measurement sensor 11, a measurement motion system, a reflective film vacuum adsorption system, a reflective film laying system, a motion control system that controls the measurement motion system and processes the laser A data processing system for the data measured by the measurement sensor;

[0065] The measuring motion system includes a horizontal two-dimensional motion platform that can move horizontally relative to the machine tool workbench and a vertical translation platform 13 fixed on the horizontal two-dimensional movement platform, and the vertical translation platform 13 is provided with the Laser measurement sensor 11;

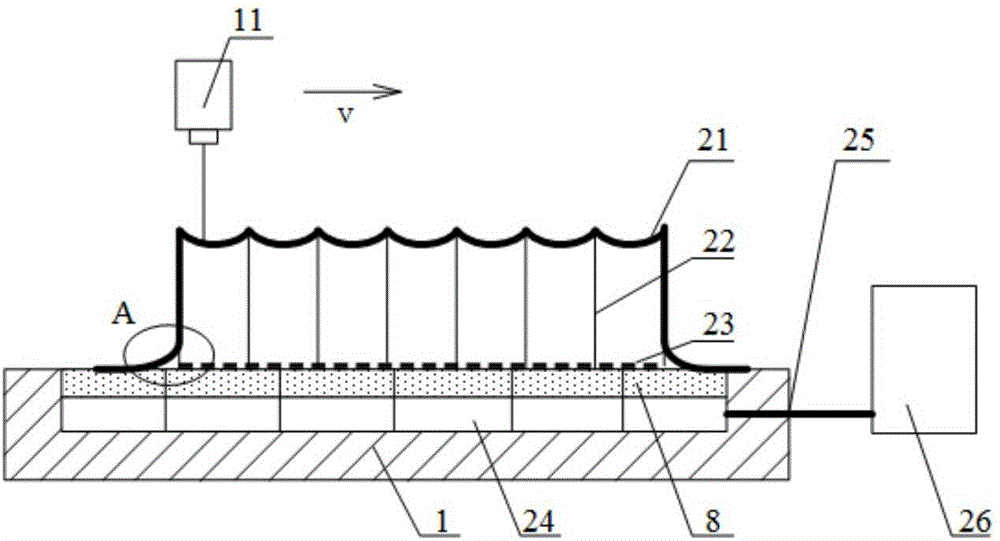

[0066] The reflective film vacuum adsorption system includes a vacuum adsorption platform 24 installed in the machine tool workbench 1, the vacuum adsorption platform 24 is provided with a breathable fixing plate 8, and the breathable ...

Embodiment 2

[0084] A device for measuring the shape of a honeycomb core, which differs from the device for measuring the shape of a honeycomb core described in Embodiment 1 in that: the transmission device is a sprocket transmission device.

[0085] The sprocket transmission device includes two chains and a driving sprocket and a driven sprocket matched with the chains. The driving sprocket is connected with the sprocket motor through the drive shaft II. The ends are fixedly connected to the two chains respectively.

[0086] The forward rotation and reverse rotation of the sprocket motor make the drive shaft II drive the chain to move, and then drive the film-drawing rod 6 to move. According to the range of motion of the film-drawing rod 6, the sprocket motor can be set rotation range.

[0087] The reflective film 21 is a PVC film.

[0088] The material of the air-permeable fixing plate 8 is microporous ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com