Contact and non-contact type dual-purpose surface roughness measuring systems

A surface roughness and contact measurement technology, applied in the direction of electrical/magnetic roughness/irregularity measurement, measuring device, electromagnetic measuring device, etc., to achieve the effect of expanding the range, accurate and reasonable measurement data, and convenient correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

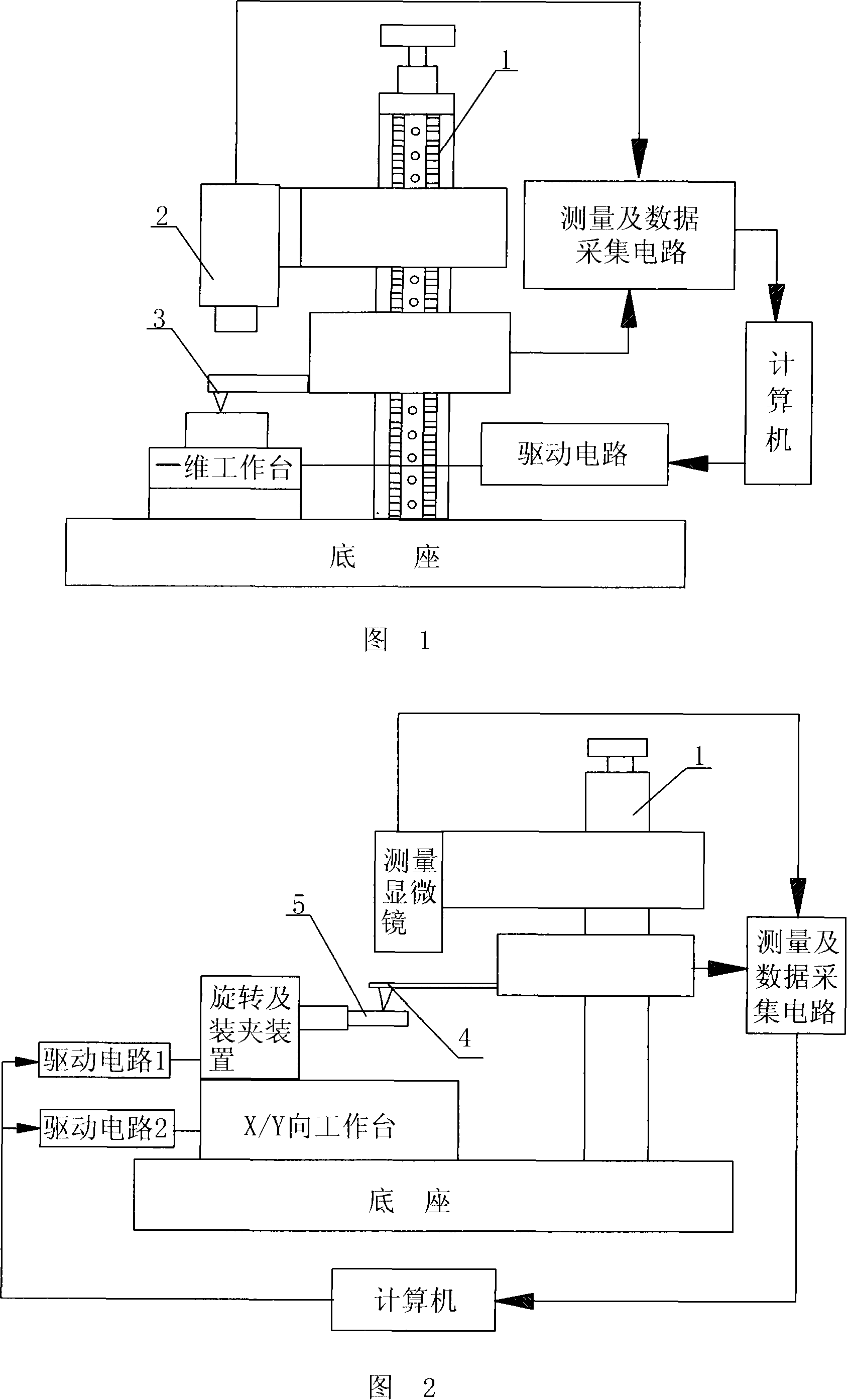

[0026] Embodiment 1 As shown in Figure 1, the contact and non-contact dual-purpose surface roughness measurement system mainly consists of a one-dimensional workbench, a column, an optical needle type non-contact measuring head 2, a diamond stylus type measuring head 3, a drive circuit, and a measurement And data acquisition circuit, computer composition. A one-dimensional workbench driven by a stepping motor is fixedly arranged on a fixed base, a fixing device for an object to be measured is arranged on the one-dimensional workbench, and a computer is connected to control the stepping motor through a drive circuit. A column 1 is fixedly arranged on the base next to the one-dimensional workbench, and the column 1 is respectively equipped with a light needle type non-contact measuring head 2 and a diamond stylus type measuring head 3 . Both the optical needle type non-contact measuring head 2 and the diamond stylus type measuring head 3 are set slidingly on the column, and the ...

Embodiment 2

[0027] Embodiment 2 The workbench of the contact and non-contact dual-purpose surface roughness measurement system is fixedly arranged on a base, and another fixed column is installed on the base, and a measuring microscope and a phase grating interferometric PGI contact sensor are movable on the column 4. The worktable is a two-dimensional moving X / Y workbench, and the X / Y workbench is driven by an AC servo motor, and the computer is connected to the AC servo motor that drives the X / Y workbench through the drive circuit 2; A rotating and clamping device for fixing warheads or tools is arranged on the workbench. The rotating and clamping device is connected to and driven by the AC servo motor of the device. The AC servo motor is connected to the computer through the drive circuit 1 . The inductance signal lines of the measuring microscope and the phase grating interferometric PGI contact sensor 4 are connected to the same measurement and data acquisition circuit, and are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com