Honeycomb core surface shape measuring method

A measuring method and technology of honeycomb core, which can be applied to measuring devices, instruments, and optical devices, etc., can solve the problem that the specific surface shape of honeycomb core materials cannot be obtained, and achieve the effects of rich information, convenient operation and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

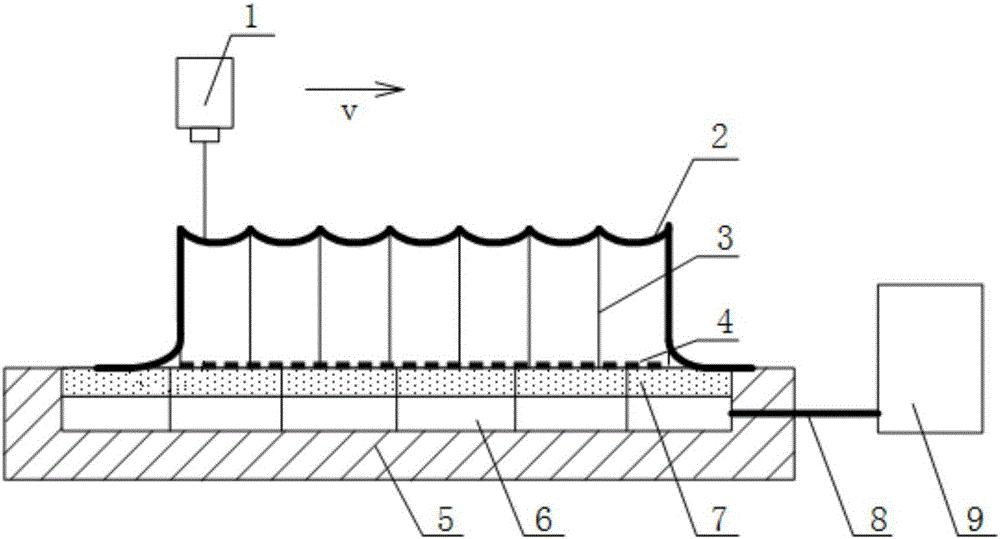

[0022] like figure 1 Shown, a kind of measuring method of honeycomb core surface shape, comprises the steps:

[0023] ① Attach a reflective film 2 on the surface to be tested of the honeycomb core 3, and make the reflective film 2 close to the surface to be tested of the honeycomb core 3 by means of vacuum adsorption, and make the reflective film 2 at the honeycomb cell be depressed downward, so The measured data will have a peak at the honeycomb wall, and the measured value minus the thickness of the reflective film 2 is the height of the honeycomb wall at this location.

[0024] ② Scanning and measuring the reflective film 2 on the surface of the honeycomb core 3 to be measured to obtain the height of the honeycomb wall of the honeycomb core 3 at different spatial positions.

[0025] In step ①, use the breathable double-sided adhesive 4 to fix the honeycomb core 3 on the cork 7, and use the air permeability of the cork 7 to absorb through the cork 7 and the breathable doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com