Low-power electronic current mutual inductor

A current transformer and electronic technology, applied in the field of transformers, can solve the problems of easy saturation of the coil, dead zone of the power supply, low emission power of the laser source, etc., and achieve the effects of simplifying the production process, expanding the measurement range, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

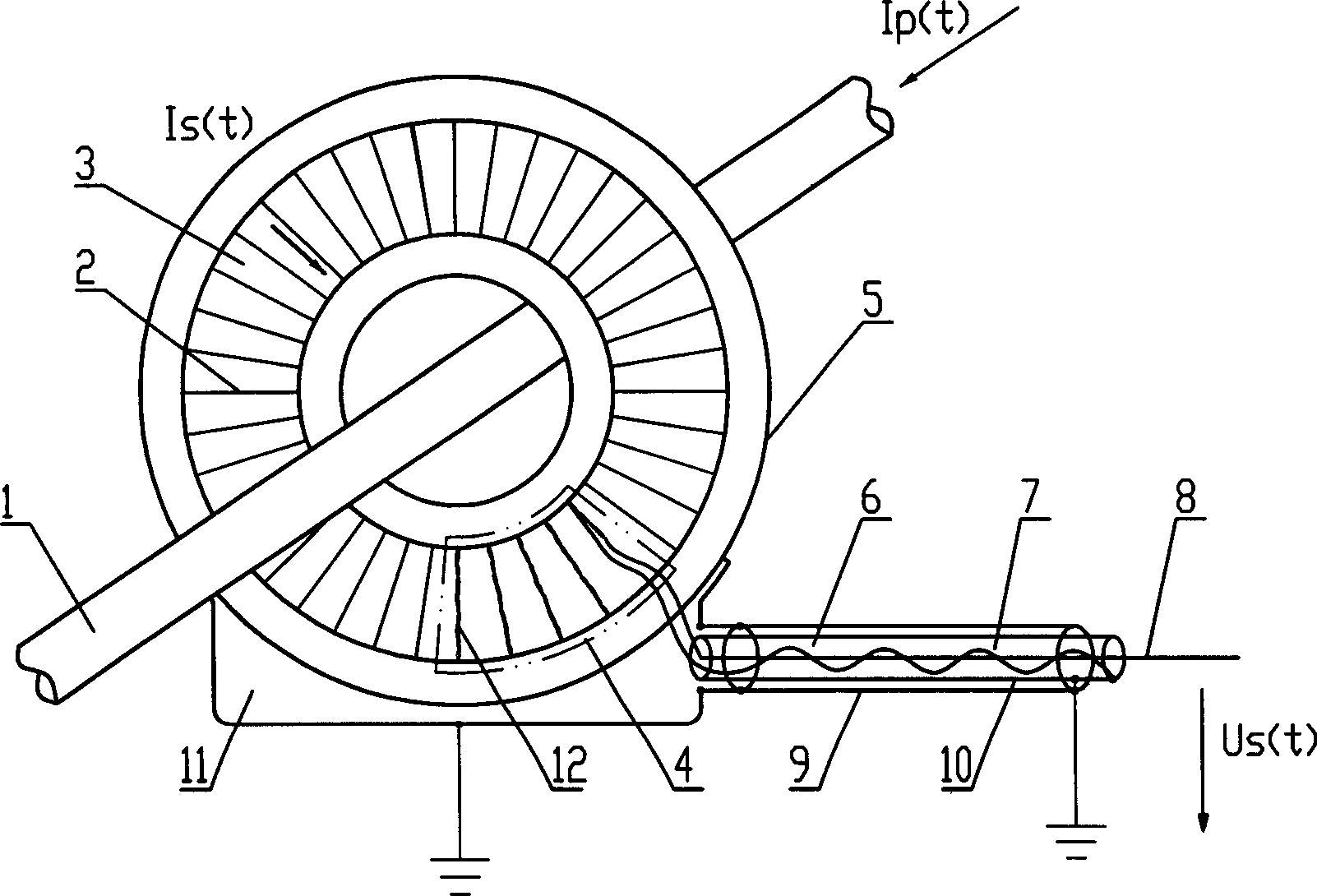

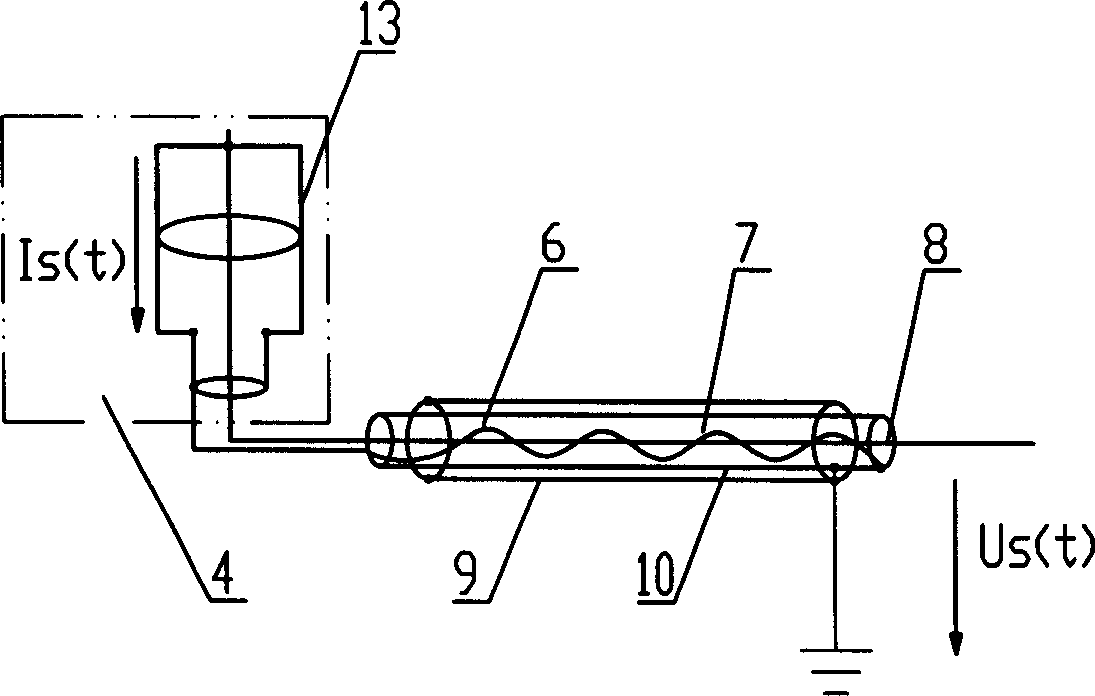

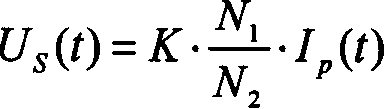

[0023] Such as figure 1 , figure 2 As shown, the present invention is a passive device, including: a primary winding 1, a secondary winding 2, a magnetic core 3, a secondary shunt resistor 4, a shielding shell 5, a double shielded twisted pair 6 and a base 11, and the primary winding 1 runs through Through the center of the magnetic core 3, the shielding shell 5 and the base 11 form a whole, the secondary copper wire is evenly wound on the annular magnetic core, and a secondary shunt resistor 4 is connected to the end of the secondary copper wire, and the secondary shunt resistor is also Evenly wound on the annular magnetic core and the secondary copper wire to form the secondary winding 2, the entire secondary winding is placed in a shielded shell 5 that will not produce short-circuit turns, and the secondary low-power voltage signal is provided by a double-shielded twisted pair 6 output.

[0024]The magnetic core 3 is made of a magnetic soft alloy strip, the shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com