Apparatus for measuring consistency of thermal deformation and deformation force of thermal bimetallic strip

A technology of thermal bimetal sheet and thermal deformation, which is applied in the direction of measuring devices, material thermal analysis, instruments, etc., can solve the problems of thermal deformation of displacement transmission rods, excessive measurement errors, accuracy stability, and low use efficiency, and achieve reduction Small test error, improve test efficiency, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

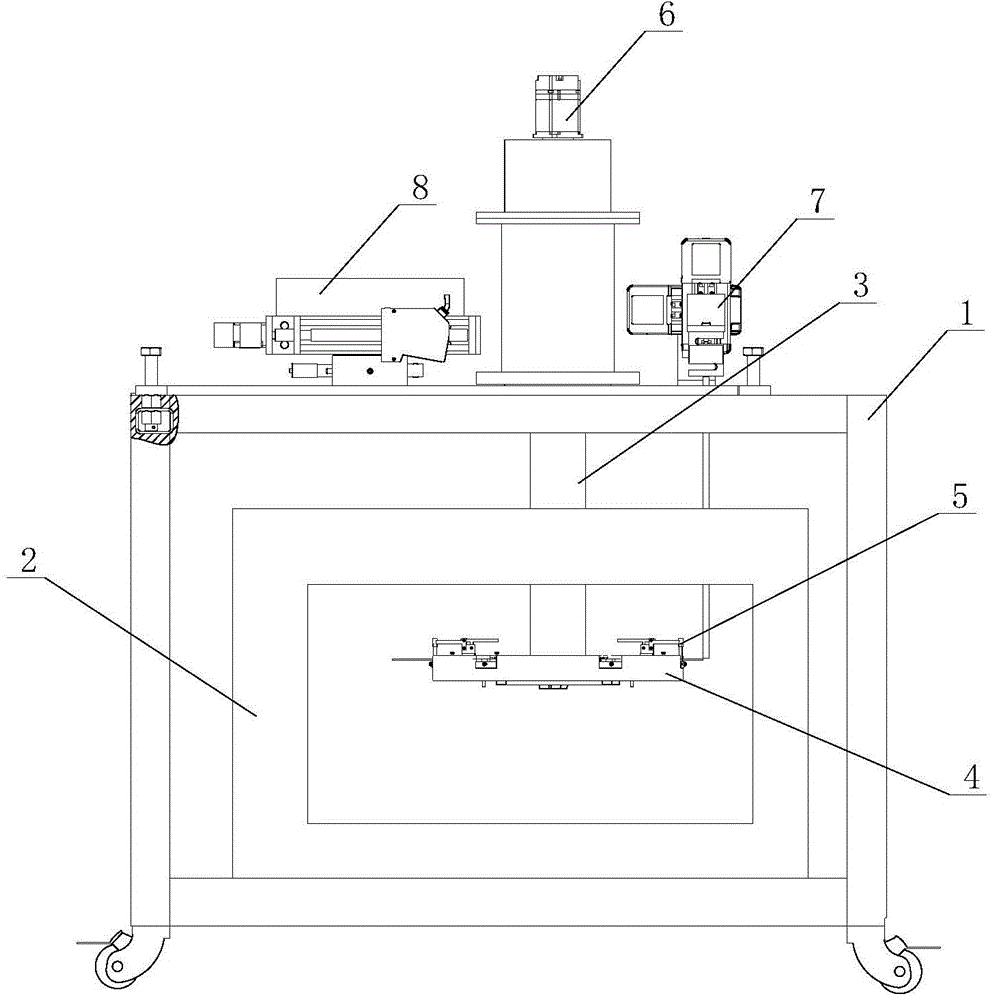

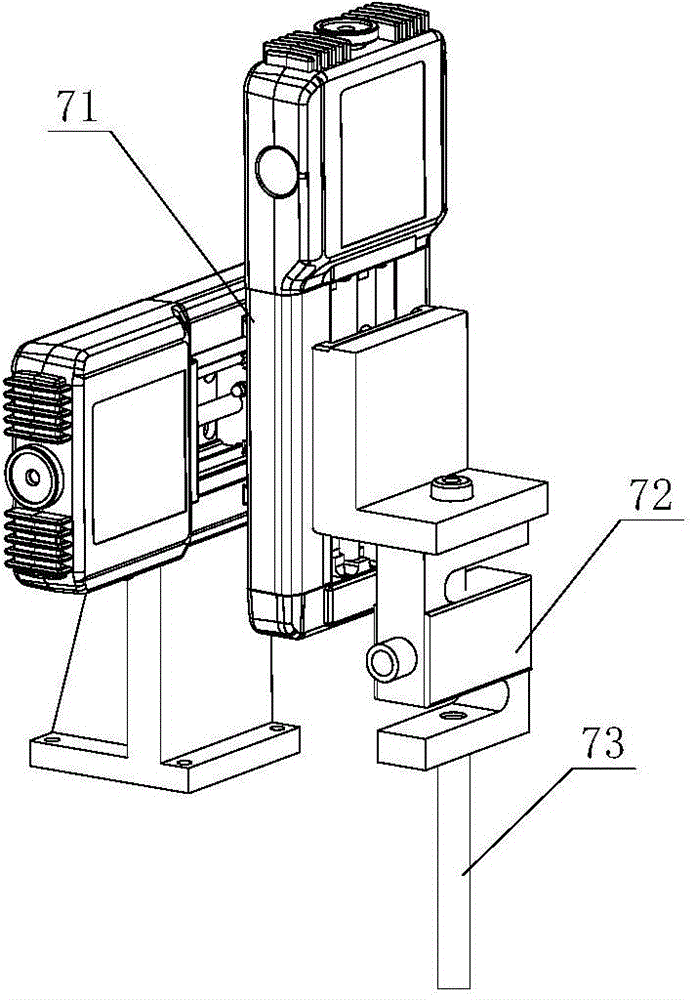

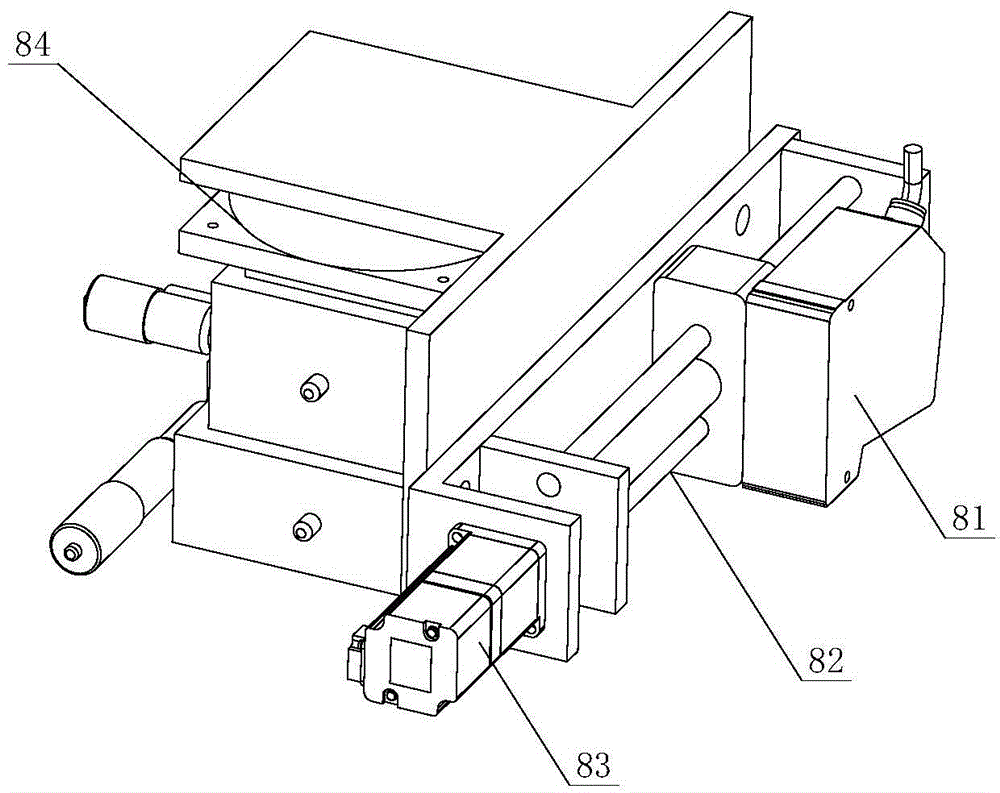

[0033] Such as figure 1 As shown, a device for measuring the thermal deformation and deformation force consistency of a hot bimetal sheet includes a horizontal installation platform 1 with a horizontal adjustment function, a high-temperature thermostat 2 arranged under the horizontal installation platform 1, and a main shaft 3 suspended in the air The turntable 4 that is arranged under the horizontal installation platform 1 and extends into the high temperature constant temperature box 2 is provided with a plurality of center-symmetrical positioning fixtures 5 for clamping the hot bimetal sheet along the circumference of the turntable 4, and the horizontal installation platform 1 is provided with There is a rotating motor 6 connected to the main shaft 3, and a thermal deformation force measuring mechanism 7 and a deflection measuring mechanism 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com