Patents

Literature

77results about How to "Convenient and detachable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

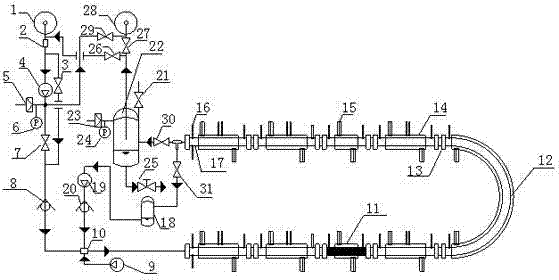

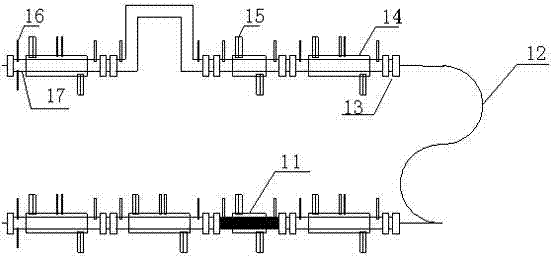

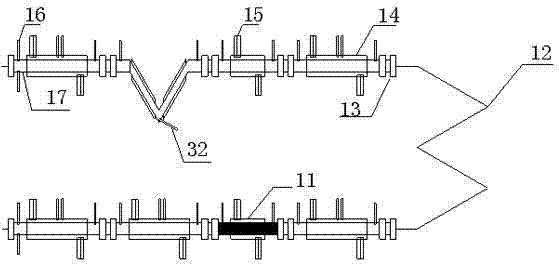

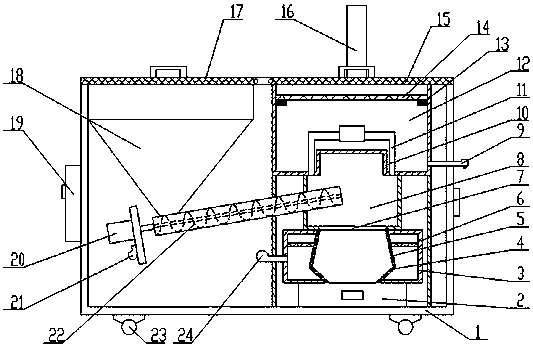

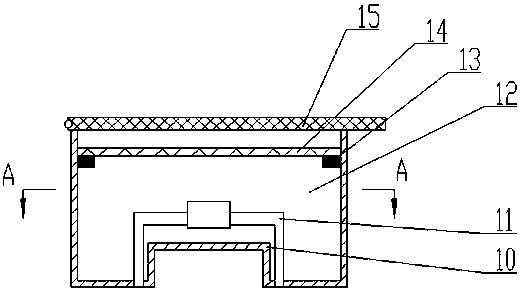

Simulating device for fluid flow safety evaluation of oil-gas pipelines

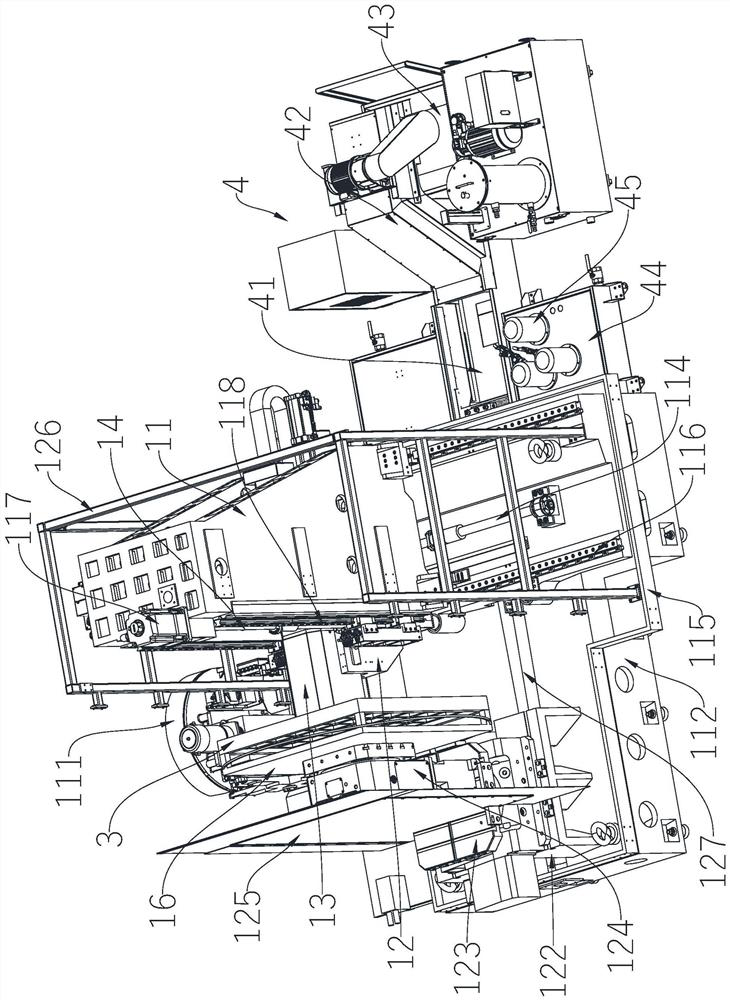

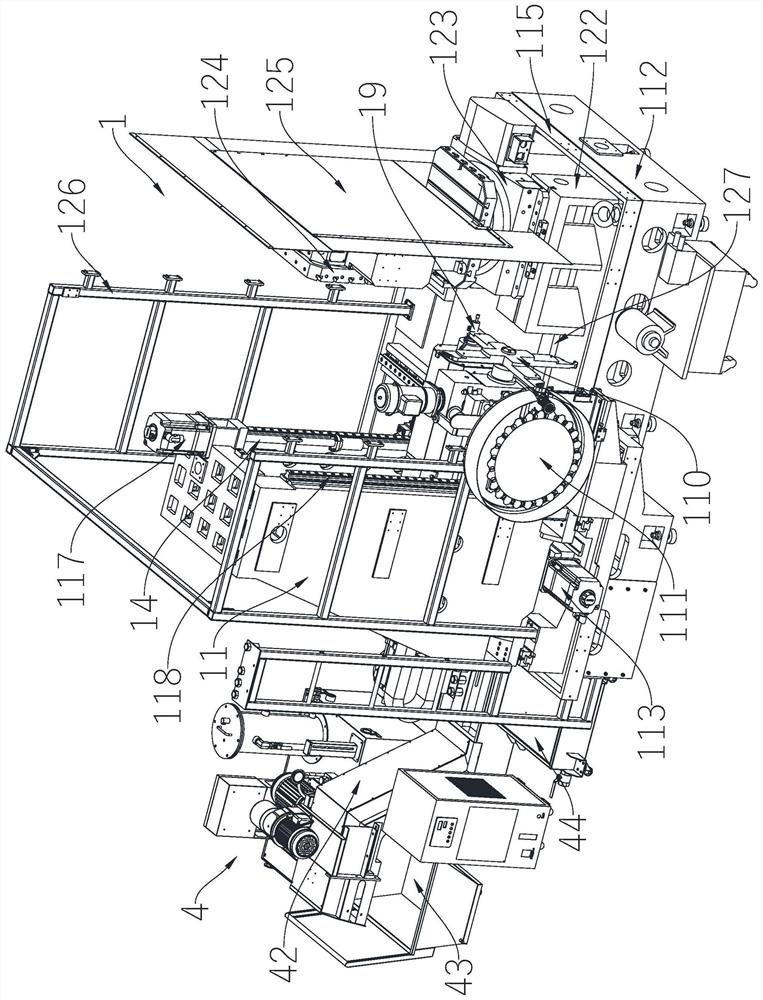

The invention discloses a simulating device for fluid flow safety evaluation of oil-gas pipelines. The device comprises a multiphase flow circulating system, a separating system, a fluid injecting system and a waste gas recovery system. The device disclosed by the invention emerges on the basis of fully considering the current fluid flow safety hotspot problem and is capable of simulating a low-temperature high-pressure environment to carry out the fluid flow safety evaluation of the oil-gas pipelines, wherein the evaluation content comprises oil-gas pipeline blockage caused by problems such as hydrate and wax deposit and the oil-gas transmission safety problem caused by pipeline corrosion. The device disclosed by the invention is not limited to the evaluation content and can also be used for exploring the research on the evaluation of multi-phase fluid flow regularity, hydrate inhibitor performance and the like. The device disclosed by the invention has the characteristics of reasonable structure, ingenious design, operational flexibility, accuracy in measurement and the like.

Owner:SOUTH CHINA UNIV OF TECH

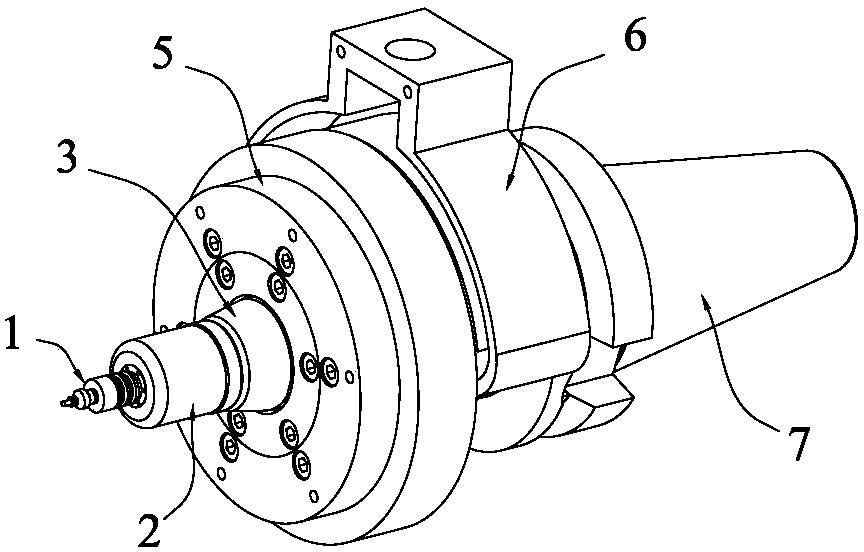

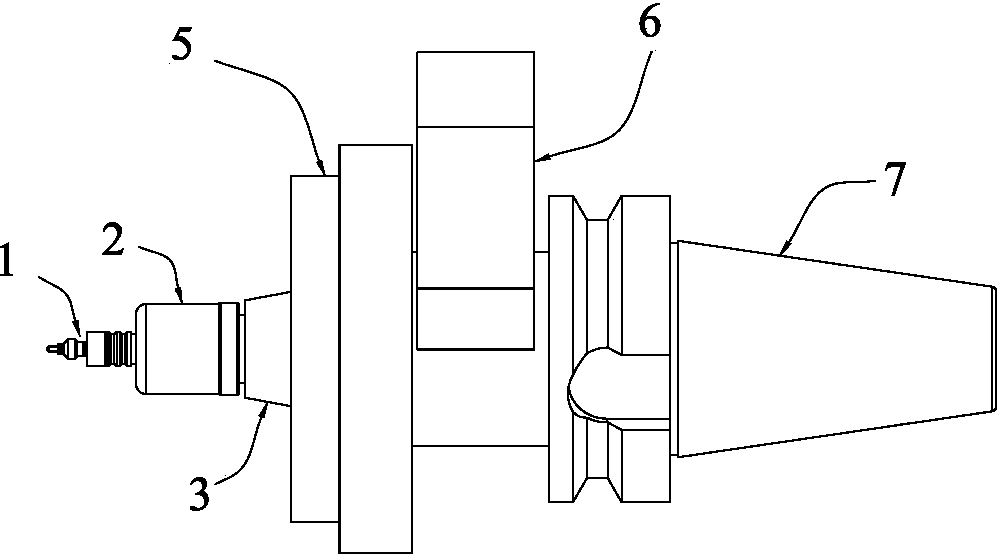

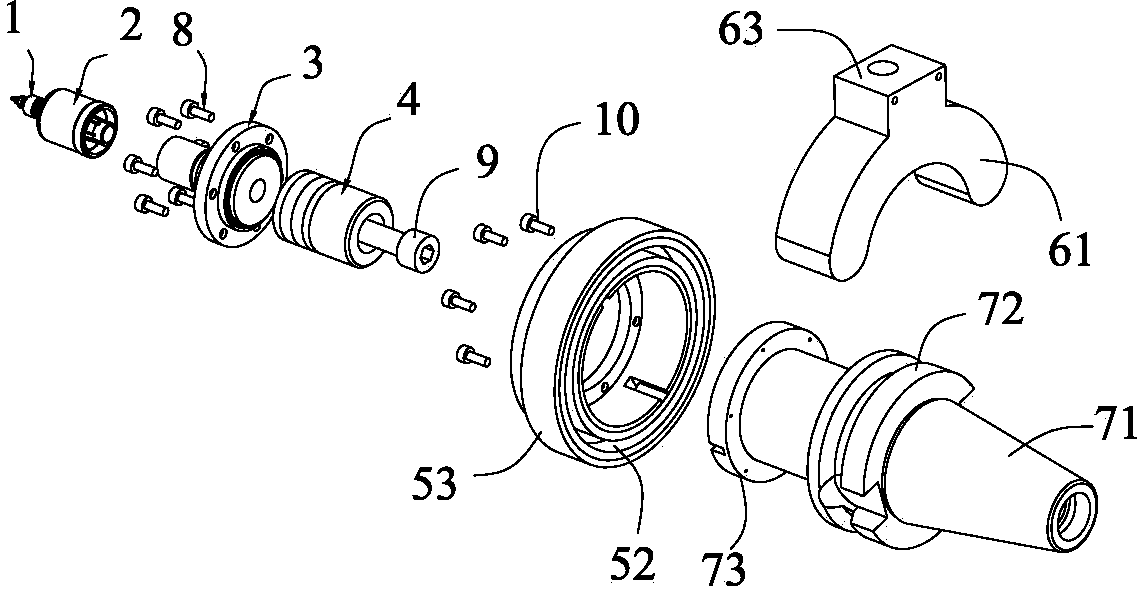

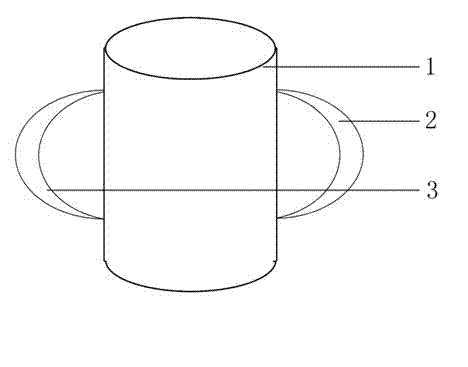

Non-contact energy transmission type ultrasonic machining device

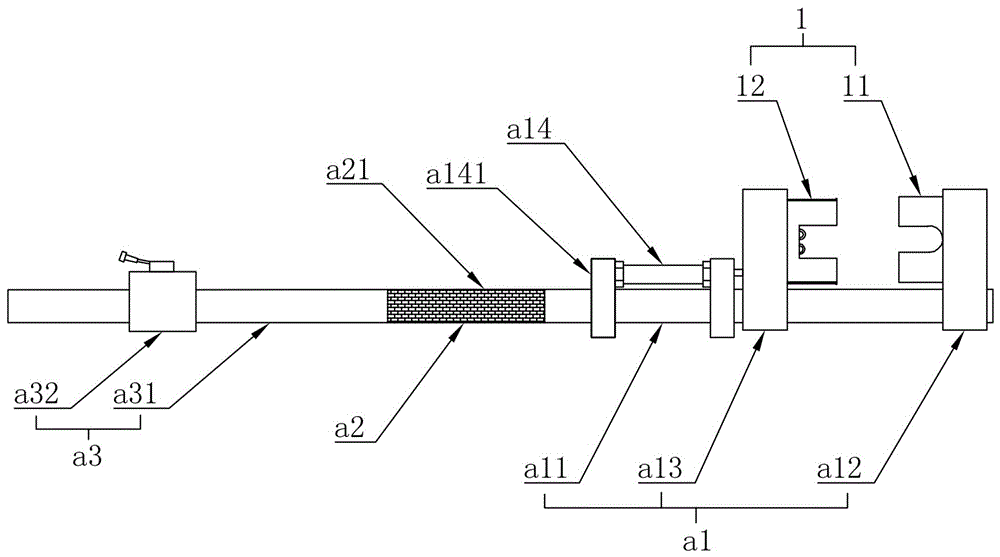

The invention discloses a non-contact energy transmission type ultrasonic machining device. The non-contact energy transmission type ultrasonic machining device comprises a grinding head, an amplitude-change rod, a front cover plate, piezoelectric ceramic, secondary magnetic ring coil, a primary magnetic ring coil and a tool handle. The grinding head, the amplitude-change rod, the front cover plate and the tool handle are sequentially connected, the piezoelectric ceramic is arranged in a concave assembly position of the tool handle, the secondary magnetic ring coil is fixed to the front cover plate, the primary magnetic ring coil is arranged on a mechanical arm of an ultrasonic machine, and gap is formed between the secondary magnetic ring coil and the primary magnetic ring coil. The non-contact energy transmission type ultrasonic machining device is ingenious and reasonable in structural design; because of the non-contact energy transmission structure design, not only is non-contact high-efficiency transmission of electric energy achieved, but also the problem of traditional slip ring abrasion in ultrasonic machining is solved, the heat generation phenomenon caused by contact friction is avoided, the rotation speed of a spindle is increased without limitations, and meanwhile the automatic tool changing requirement of a machining center can be met; moreover, because no exposed conductors exist, electric energy transmission is not influenced by environments, and the non-contact energy transmission type ultrasonic machining device is good in working stability, safe, reliable, capable of keeping work for a long time and high in working efficiency.

Owner:张增英

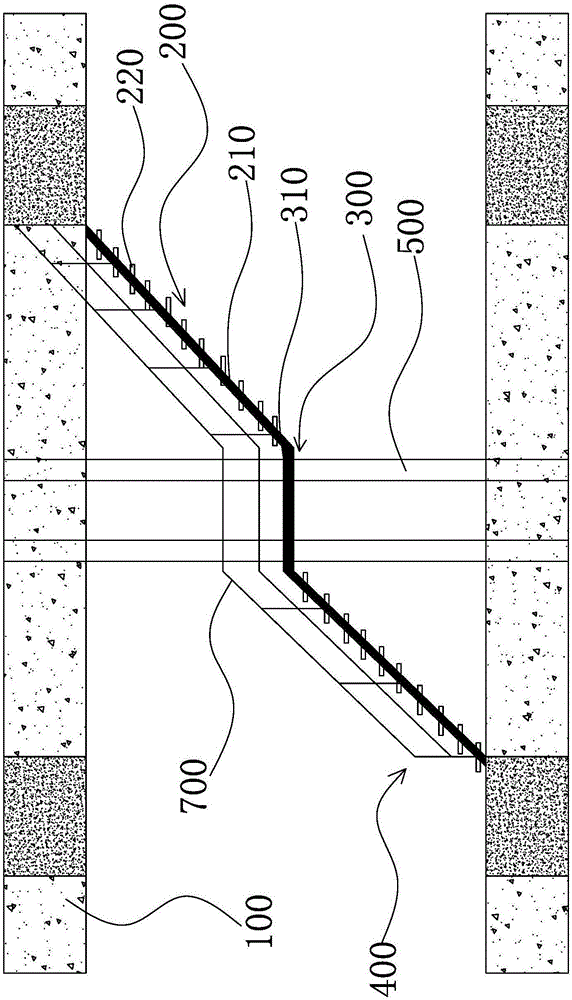

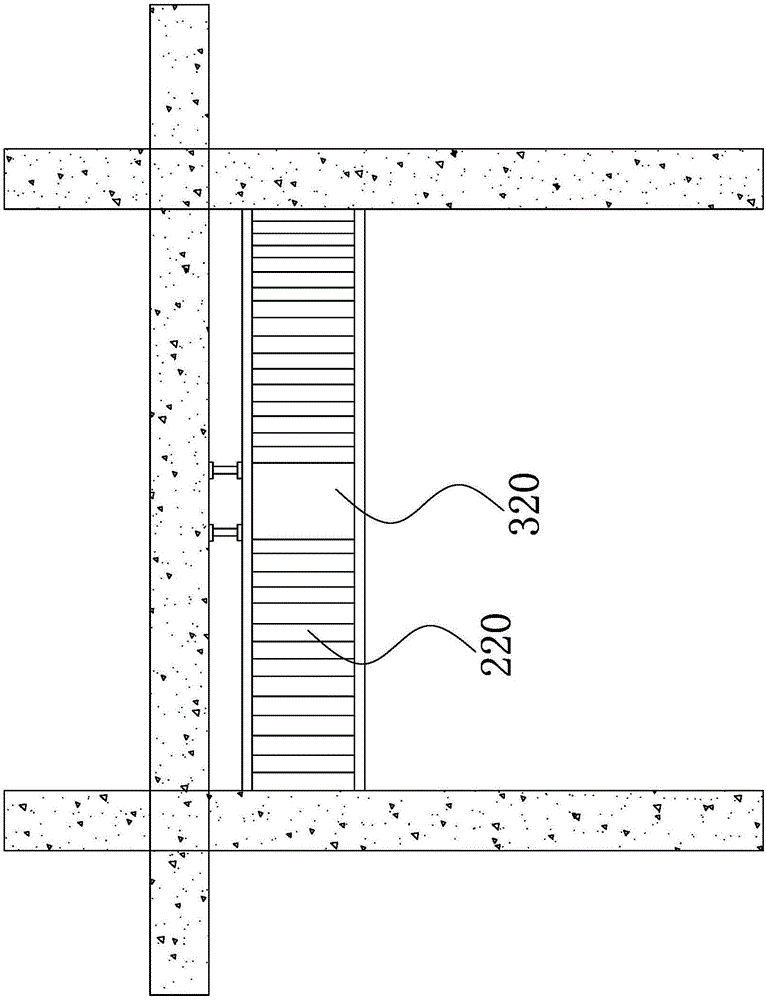

Hanging type construction staircase of deep foundation pit and construction method thereof

InactiveCN106836851ASatisfies the shortcomings of large site changesImprove the installation environmentShaping building partsReinforced concreteRebar

The invention provides a hanging type construction staircase of a deep foundation pit and a construction method thereof. The hanging type construction staircase is located between two reinforced concrete horizontal supports and comprises a first step section, a second step section and a third step section, wherein the first step section, the second step section and the third step section are connected in a head-to-tail mode to be a Z-shaped structure. According to the hanging type construction staircase of the deep foundation pit, the reinforced concrete horizontal supports in the deep foundation pit engineering are utilized, the staircase is suspended on the supports, the mounting environment of the construction staircase can be greatly expanded, and the use performance is improved; and in addition, the staircase can be lengthened or removed by sections according to the engineering progress, the shortcoming that the site change is large during construction of the deep foundation pit is overcome, and good adaptability is achieved.

Owner:浙江二十冶建设有限公司

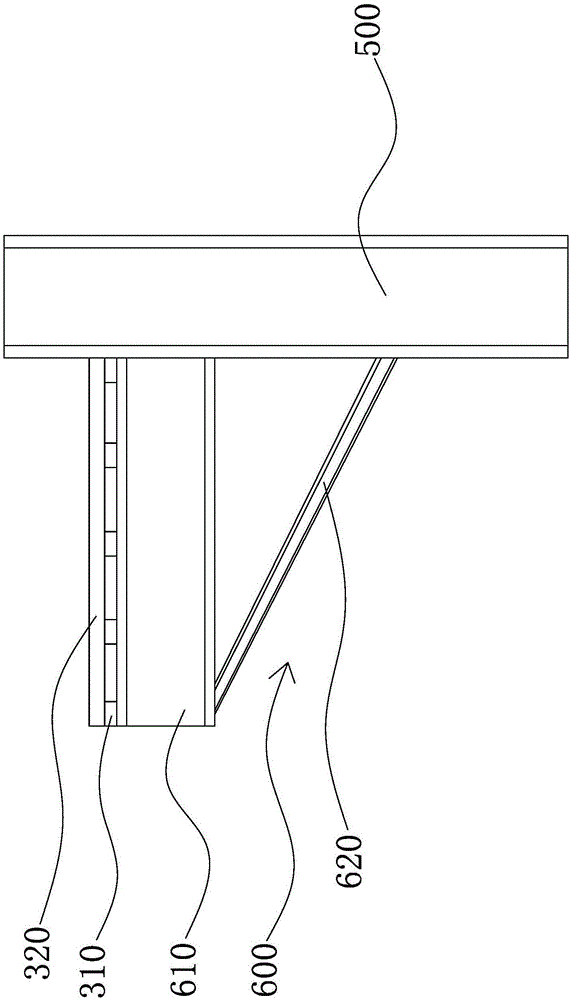

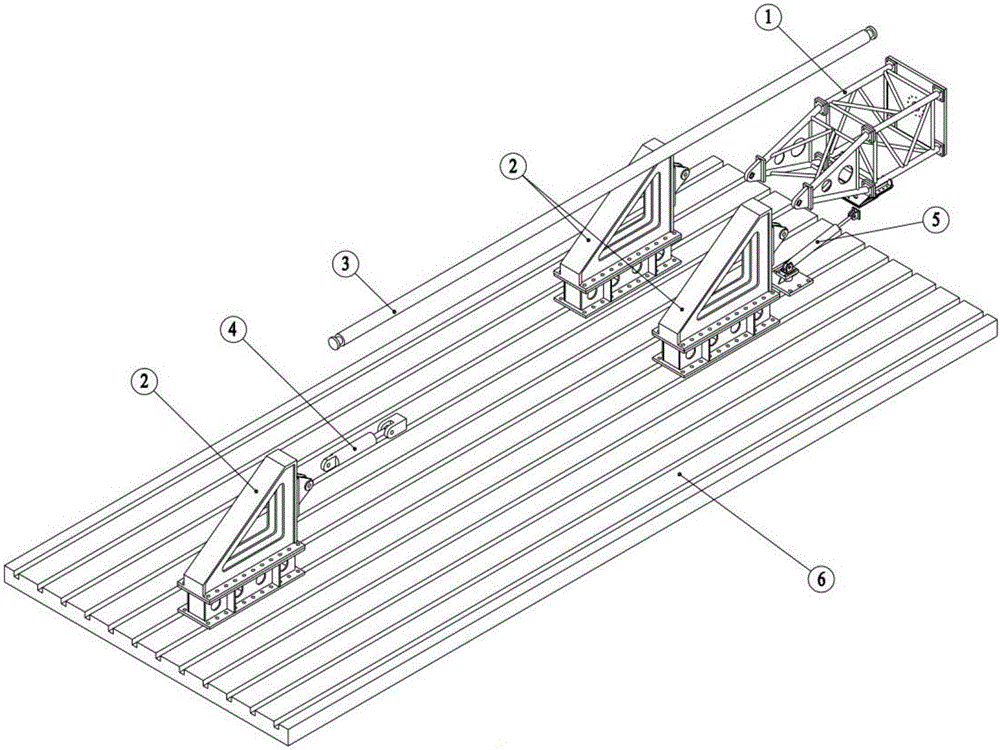

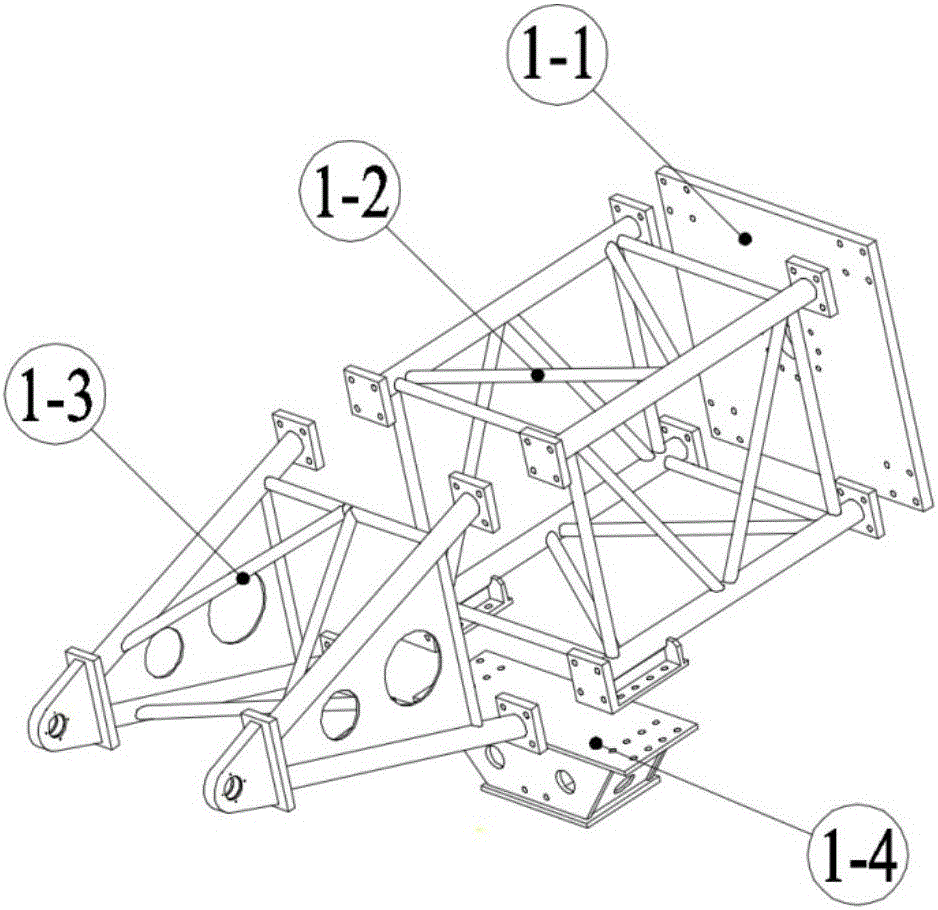

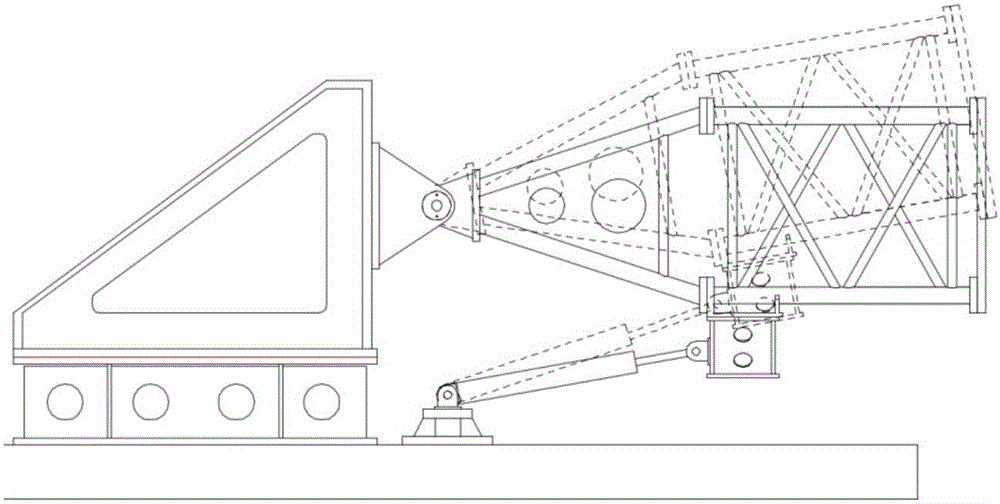

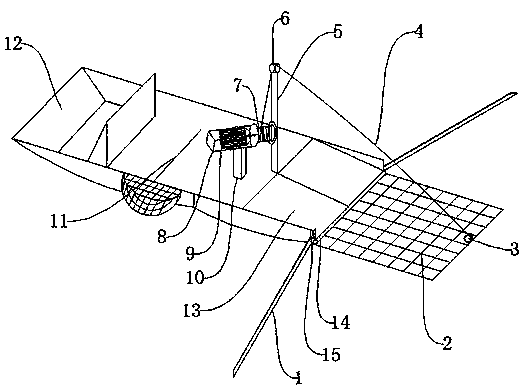

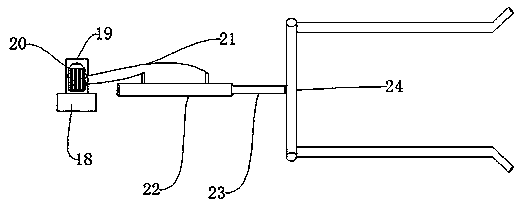

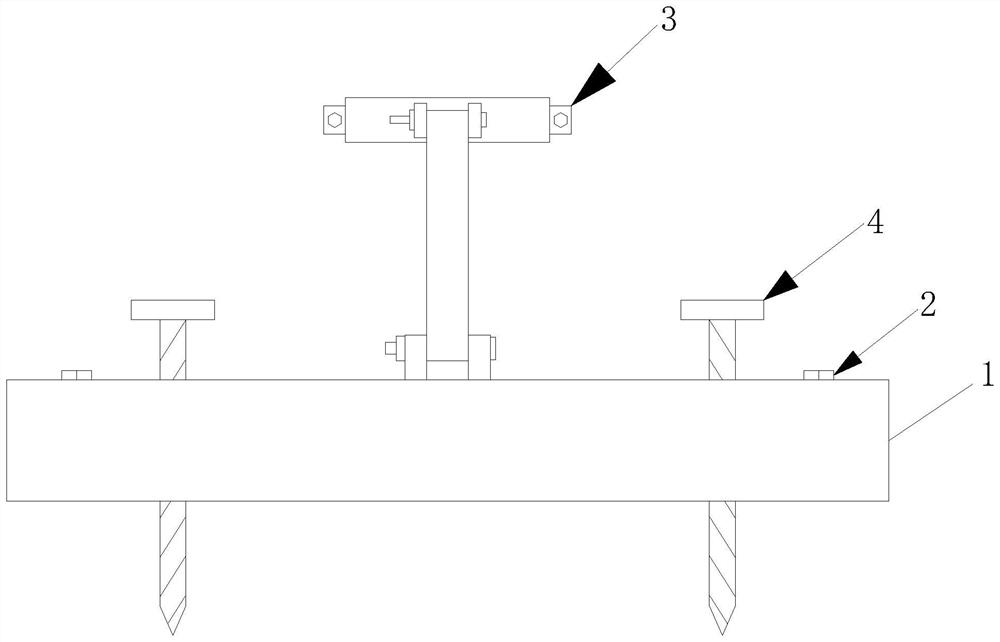

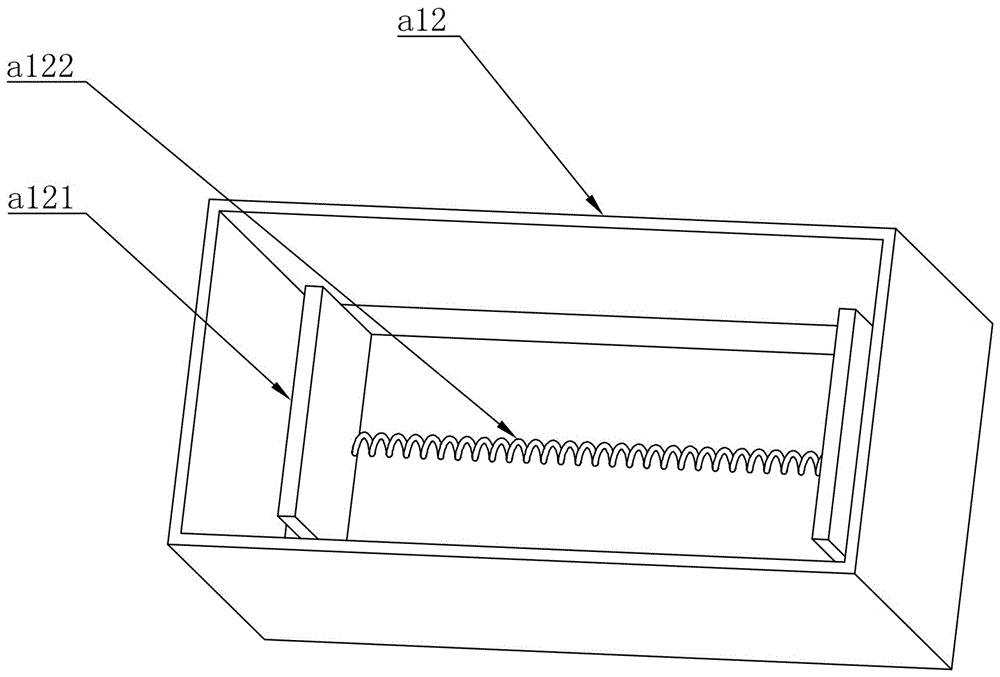

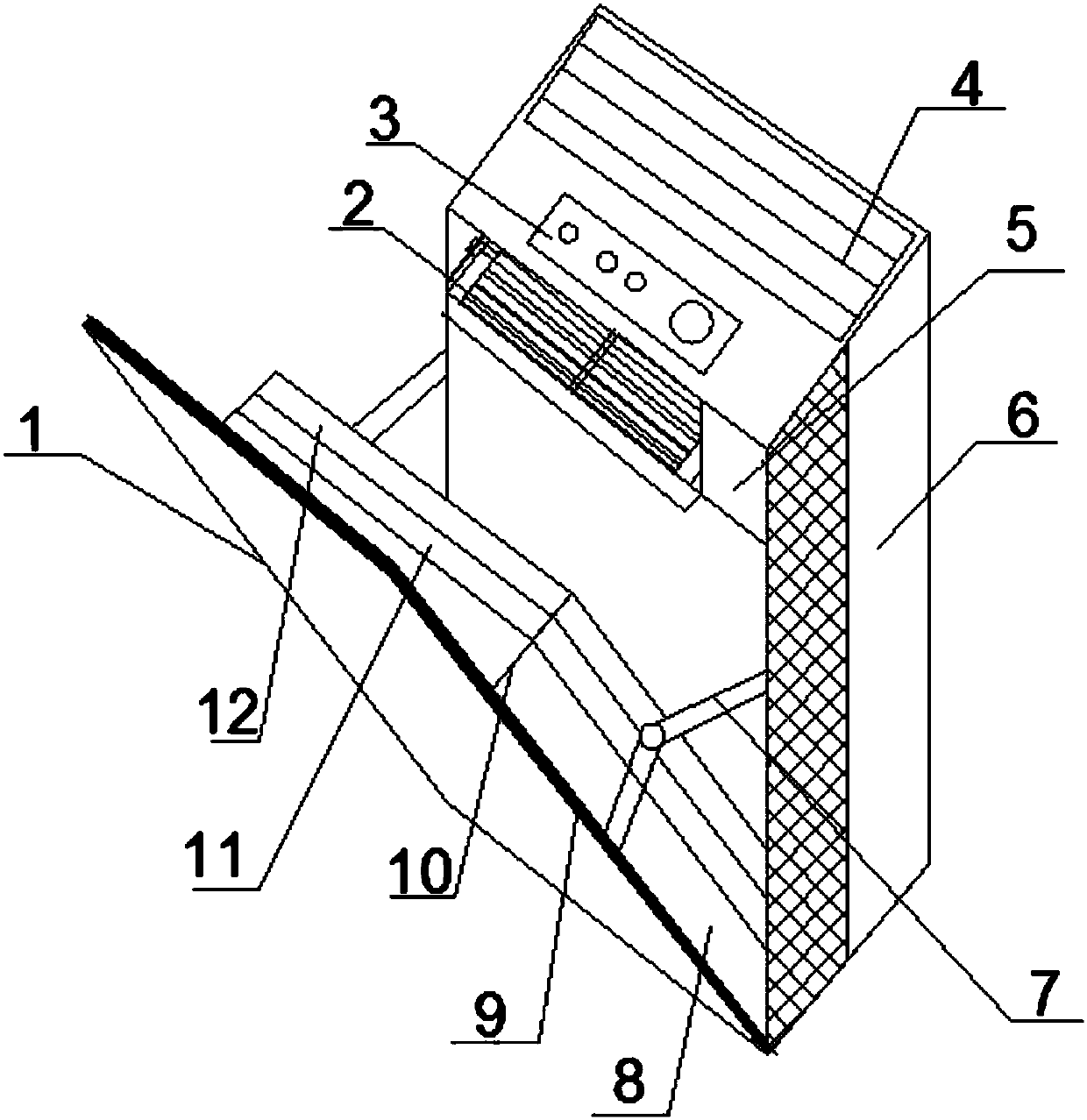

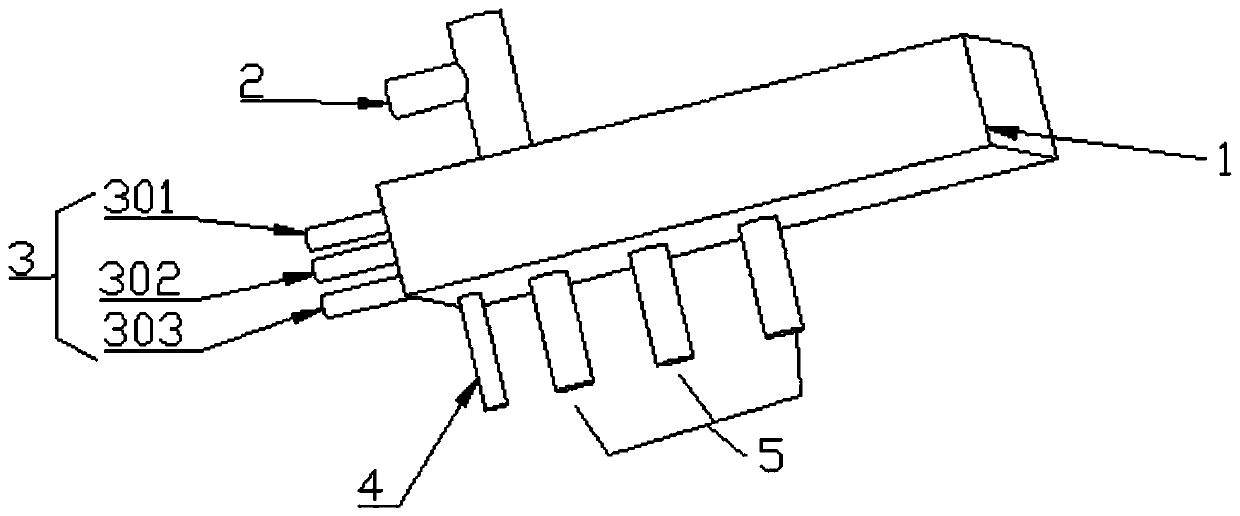

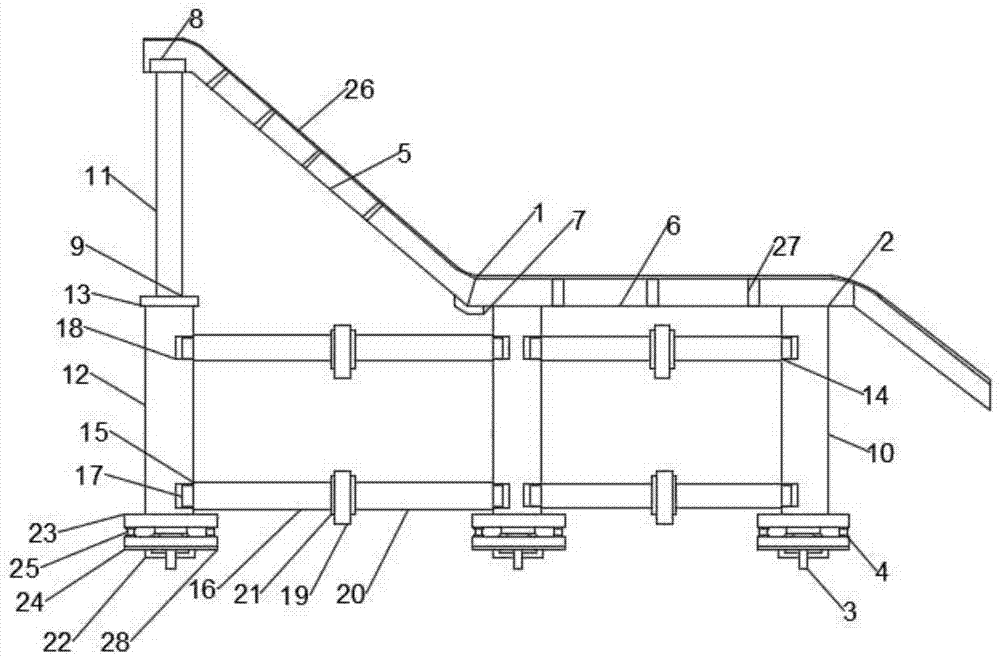

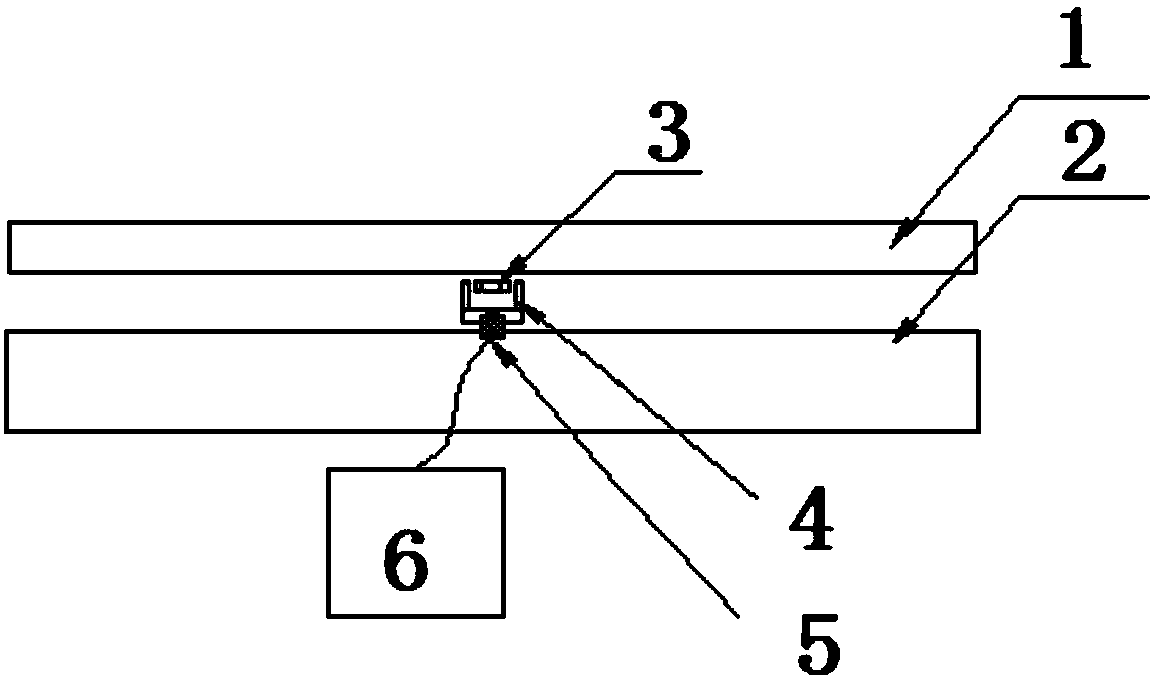

Marine dynamic umbilical cable tension bending combination fatigue test device easy to adjust

ActiveCN105890996AReduce dosageDesignableMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesStress conditionsModularity

The invention provides a marine dynamic umbilical cable tension bending combination fatigue test device easy to adjust. The device comprises a swing head device, movable frames, a test umbilical cable, a tensile loading device, a bending loading device and an artificial ground foundation. The test device applies constant tension loads to the umbilical cable through the movable frame and the tension loading device at one end, and applies circulating bending loads through the two three-direction movable frames, the swing head device and the bending loading device at the other end, accordingly the stress condition of the umbilical cable is simulated under the actual marine environment and floating motion, and fatigue service life of the dynamic umbilical cable in the actual service process is verified. A distributed modular design method is adopted to a tester, disassembly and assembly can be achieved according to of objects with different lengths and different apertures, and the device has the advantages of being convenient to install and operate and the like.

Owner:DALIAN UNIV OF TECH

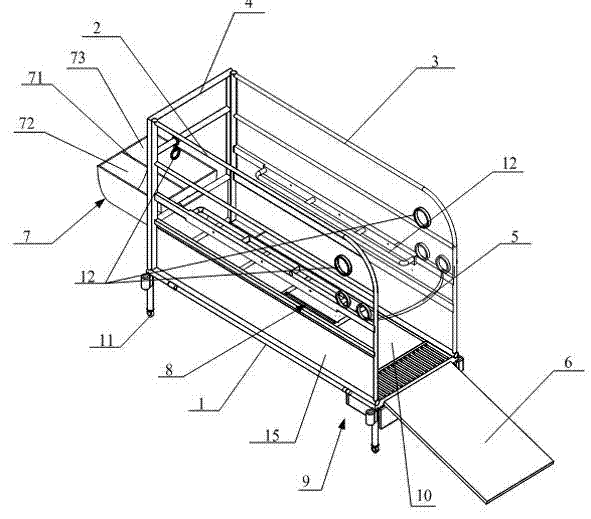

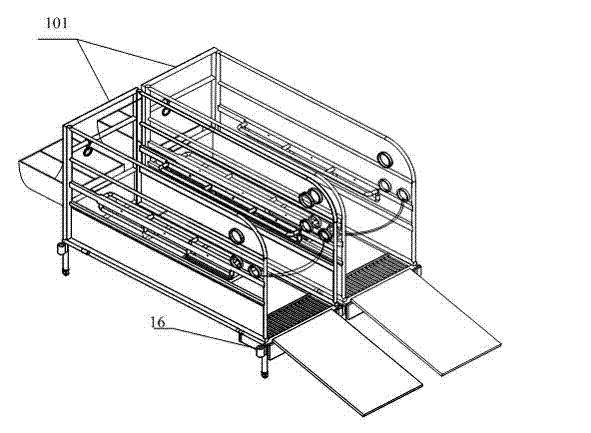

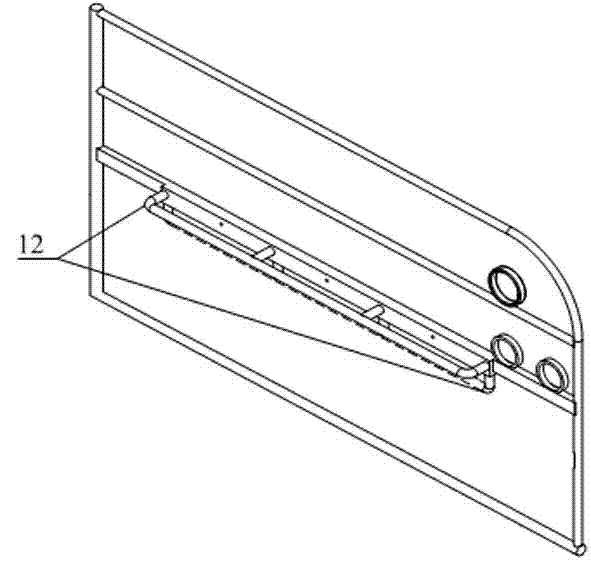

Ruminant movable metabolic cage

InactiveCN102283132AImprove applicabilityEasy to moveAnimal feeding devicesAnimal housingAgricultural engineeringPulley

The invention relates to an animal metabolism cage, in particular to a movable metabolism cage for a ruminant, which at least comprises a unit metabolism cage, wherein the unit metabolism cage comprises a bottom bracket, left and right side frames and a front frame are arranged on the bottom bracket, and one end of the left side frame and one end of the right side frame are both connected with the front frame; the rear ends of the left and right side frames are both at least provided with a metal chain for constraining the ruminant; a pedal board is arranged on the bottom bracket; the metal chain is easy to detach, a pedal board is arranged on the bottom bracket on the same side as a metal chain; the pedal board can be connected with the bottom bracket through a hinge and can be detached freely; a feeding trough is formed on the front frame; the front frame and left and right frames are all formed by connecting rod pieces with bolts, and therefore can be detached conveniently; a urinedischarging device, a dung discharging device and an antiskid device are arranged on the bottom bracket; the legs of the bottom bracket are welded with pulley wheels that can be braked; and movable side fences are hinged with the left and right side frames, and the cage can be arranged at a vertical or horizontal position according to the size of the ruminant.

Owner:LANZHOU UNIVERSITY

Riverway garbage collection device for environment protection project

InactiveCN108643143AReduce volumeConvenient and detachableWater cleaningGeneral water supply conservationHydraulic pumpEngineering

The invention discloses a riverway garbage collection device for the environment protection project. The riverway garbage collection device comprises a ship body, a hoisting rod and a hydraulic pump.The front end of the ship body is provided with a first rotation shaft and a second rotation shaft. A collection frame is arranged on the outer side of the first rotation shaft. A garbage storage areais arranged at the tail of the first rotation shaft. A baffle is arranged on the outer side of the second rotation shaft. A first pulley is arranged at the top end of the collection frame, the hoisting rod is arranged on the surface of the ship body, a second pulley is arranged on the top of the hoisting rod and provided with a sliding rope, a rope winder is arranged at the bottom of the slidingrope, a motor shell is arranged on one side of the rope winder, a base is arranged at the bottom of the motor shell, and a motor is arranged in the motor shell. The riverway garbage collection devicehas the beneficial effects that the size is small, the riverway garbage collection device can enter the small drainage basin for work, great assistance is achieved for environmental sanitation work, the operation area is large, operation is simple, and the operation efficiency is greatly improved.

Owner:黄春生

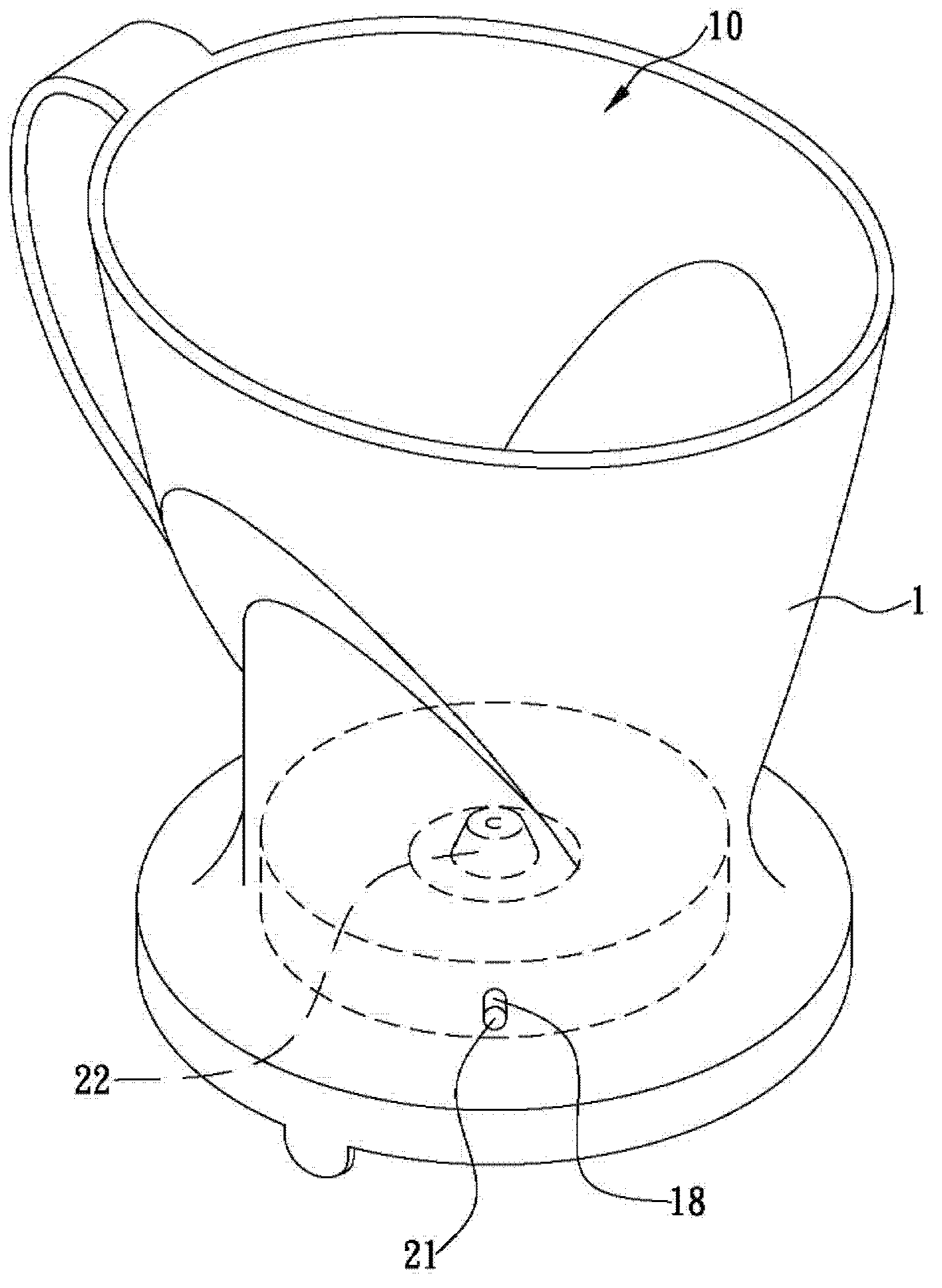

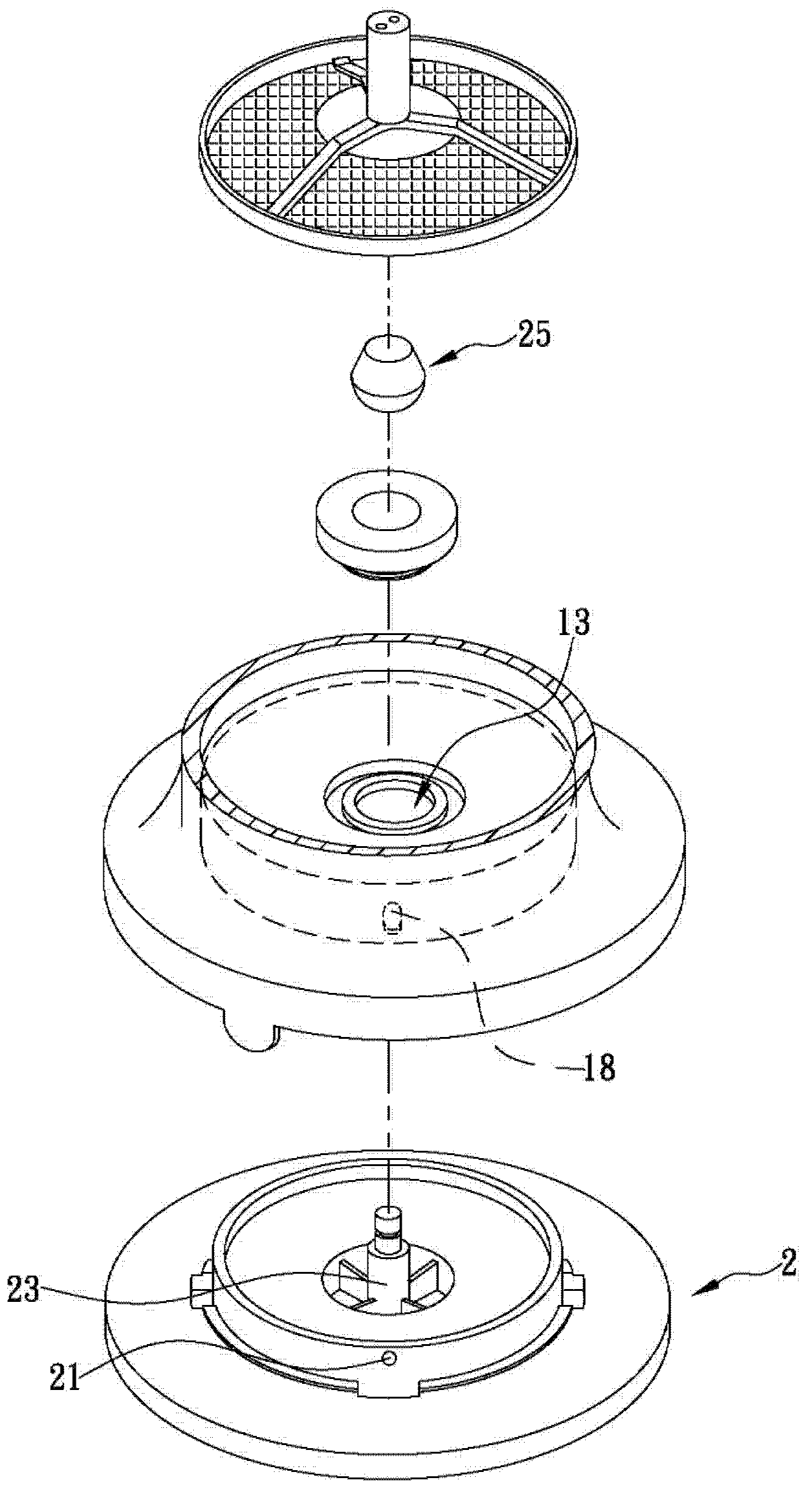

Detachable tea making tool with convenient cleaning function

ActiveCN103799791AConvenient and detachableDetachable and easy to cleanDomestic vesselsMechanical engineeringEngineering

Owner:刘明桐

Portable movable-connection neurologic nursing device

The invention discloses a portable movable-connection neurologic nursing device which comprises a bottom plate, a lying device, a folding device and a folding supporting device. The lying device is arranged in an upper-end mounting groove of the bottom plate, a mounting frame is arranged in the middle of the upper end of a folding plate in the lying device, a lying plate is arranged in the mounting frame, fastening bolts are symmetrically arranged in threaded holes on two sides of the mounting frame, and a bottom-end thread of each fastening bolt is detachably connected with a side face threaded hole of the lying plate. The portable movable-connection neurologic nursing device is simple in structure; convenience for carrying and using of the device itself is realized through the folding device and the folding supporting device, and great convenience is brought to patient's use; optimal lying angle of a patient can be adjusted through the lying device according to using needs, so that nursing comfort of the patient is ensured, working burden of medical staff is relieved, and nursing efficiency of the patient is improved.

Owner:王玉丽

LED lighting lamp with moistureproof function

InactiveCN108317446AAvoid erosionEasy to clean and maintainLighting support devicesGas-tight/water-tight arrangementsEngineeringLight fixture

The invention discloses an LED lighting lamp with the moistureproof function, and belongs to the technical field of lighting. The lamp comprises a connecting base, a lampshade, a lamp source base andan LED lamp source; the connecting base is fixedly provided with a groove, a thread hole is formed in the bottom of the groove, the thread hole is in threaded connection with a thread rod, one end ofthe thread rod is rotatably connected with an adsorption plate, supporting feet are fixedly arranged at the upper end of the connecting base, and are fixedly provided with suction cups, the lower endof the connecting base is fixedly connected with a connecting rod, the connecting rod is fixedly connected with the upper end of the lamp source base, the LED lamp source is fixedly arranged on the lower end of the lamp source base, a fixed block is fixedly arranged at the upper end of the lampshade, storage grooves are fixedly formed I the two sides of the fixed block, limiting blocks are arranged in the storage grooves in a sliding manner, and the limiting blocks are elastically connected with the walls of the storage grooves through springs. The problems that an existing LED lamp does not have the dampproof and moistureproof functions, and mounting is tedious, and detaching and using are not convenient are solved.

Owner:浙江朗科照明有限公司

Curtain

ActiveCN110575043AEasy to cleanPrevent over-rotationBatteries circuit arrangementsPelmetsEngineeringElectrical and Electronics engineering

The invention discloses a curtain. The curtain comprises a box, an opening is arranged at the lower end of the box, two connecting rods parallel to each other are arranged in the box, thick curtain cloth is connected to the left part and right part of one connecting rod through connecting rings, thin curtain cloth is connected to the left part and right part of the other connecting rod through connecting rings, the thick curtain cloth and the thin curtain cloth pass out from the opening, a plurality of cleaning assemblies connected with the box are arranged between the two connecting rods, thecleaning assemblies are used for carrying out knocking cleaning on the thick curtain cloth and the thin curtain cloth, and in order to carry out labor-saving cleaning on the plurality of layers of curtains, the cleaning assemblies can conveniently carry out dust removing treatment on the thick curtain cloth and the thin curtain cloth.

Owner:安徽省唯一纺织有限公司

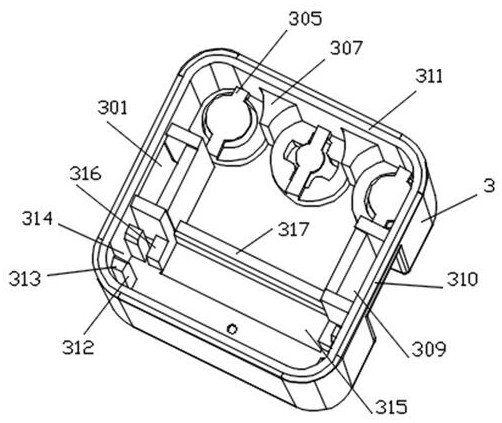

Building block type sensor

InactiveCN112116854AAvoid damageConvenient and detachableCasings/cabinets/drawers detailsEducational modelsArchitectural engineeringStructural engineering

The invention discloses a building block type sensor, and belongs to the technical field of intelligent education kits. The building block type sensor comprises a shell and a sensor body installed inthe shell, wherein the shell comprises a bottom shell and a top cover, a buckling piece is arranged at the bottom of the top cover, a buckling position is arranged at the top of the bottom shell, andthe top cover and the bottom shell are clamped into the buckling position at the top of the bottom shell through the buckling piece at the bottom of the top cover to be detachably connected in a buckled mode; a plurality of evenly-distributed plug pin round holes are formed in the bottom of the bottom shell, cross plug pin holes are formed between the plug pin round holes, the plug pin round holesand the cross plug pin holes extend through hole grooves to be formed in the bottom shell 3, and limiting baffles are arranged at the bottoms of the hole grooves; and a round hole is formed in the top of the top cover, and a probe component of the sensor body works with external induction through the round hole. The building block type sensor has the advantages of being convenient to disassembleand assemble, high in stability, low in cost and convenient to build.

Owner:广州新烨数码科技股份有限公司

Tree supporting device for mountain ecological management and using method thereof

PendingCN114557228AStable supportAvoid complex processCultivating equipmentsAnimal scienceStructural engineering

Owner:江苏九州生态科技股份有限公司

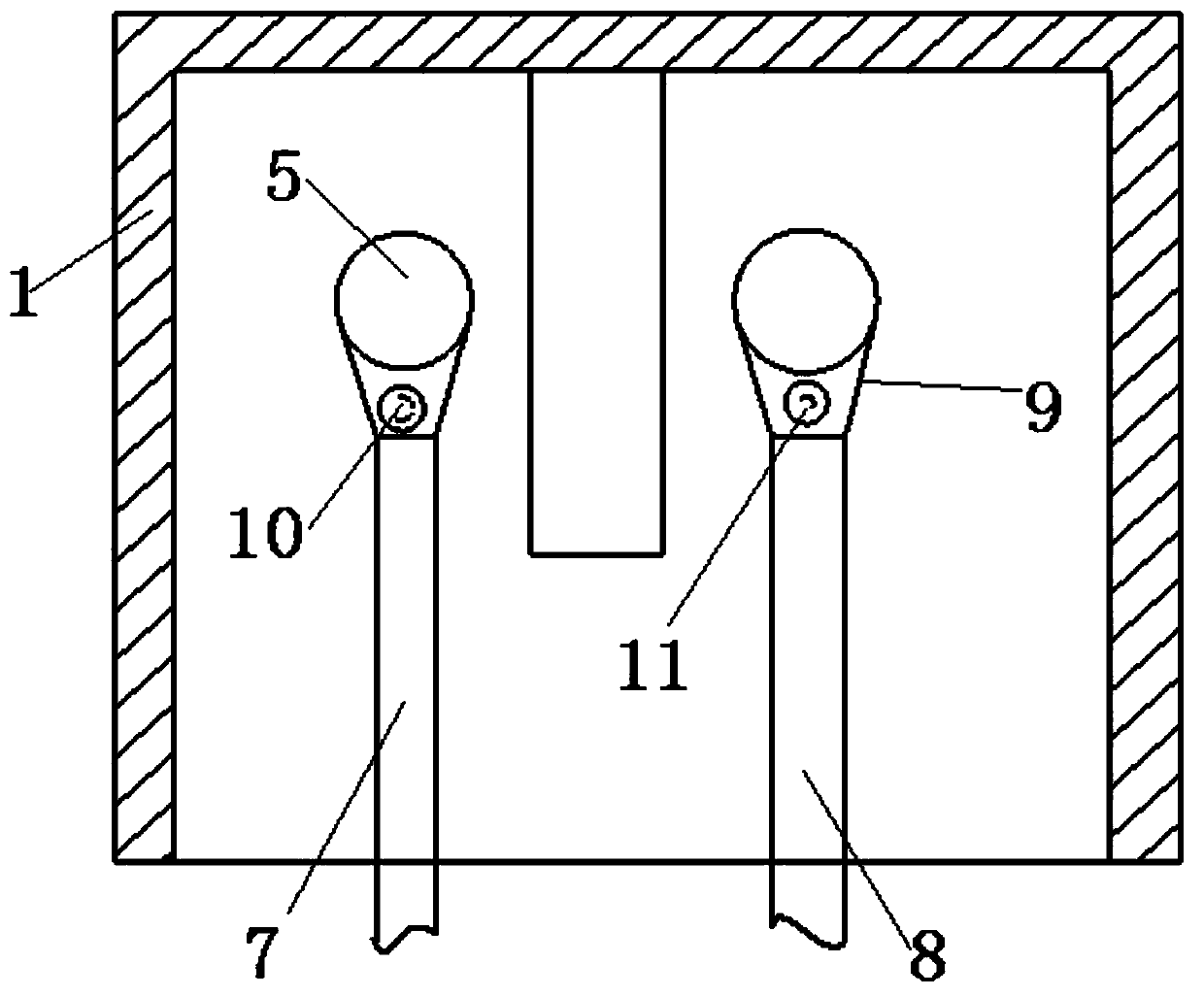

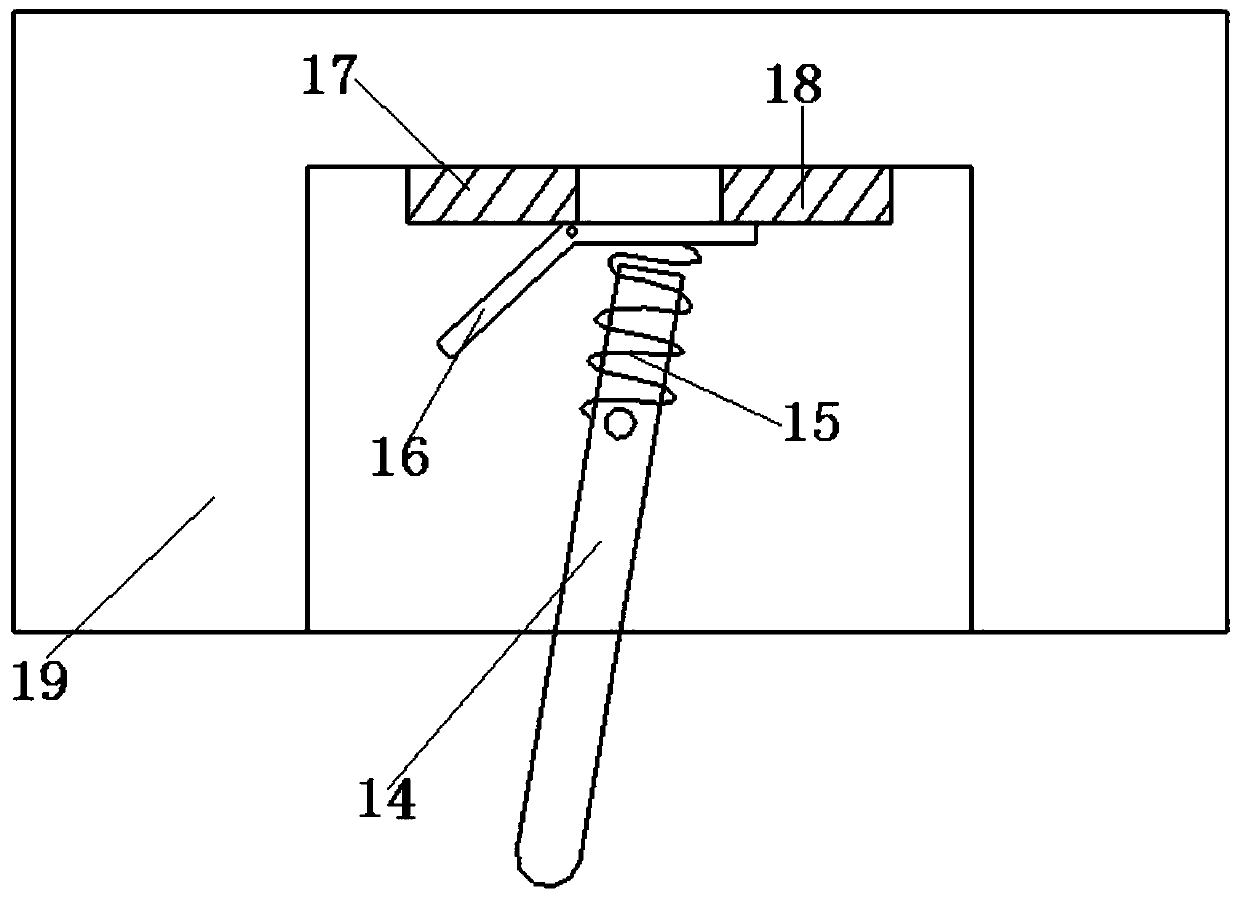

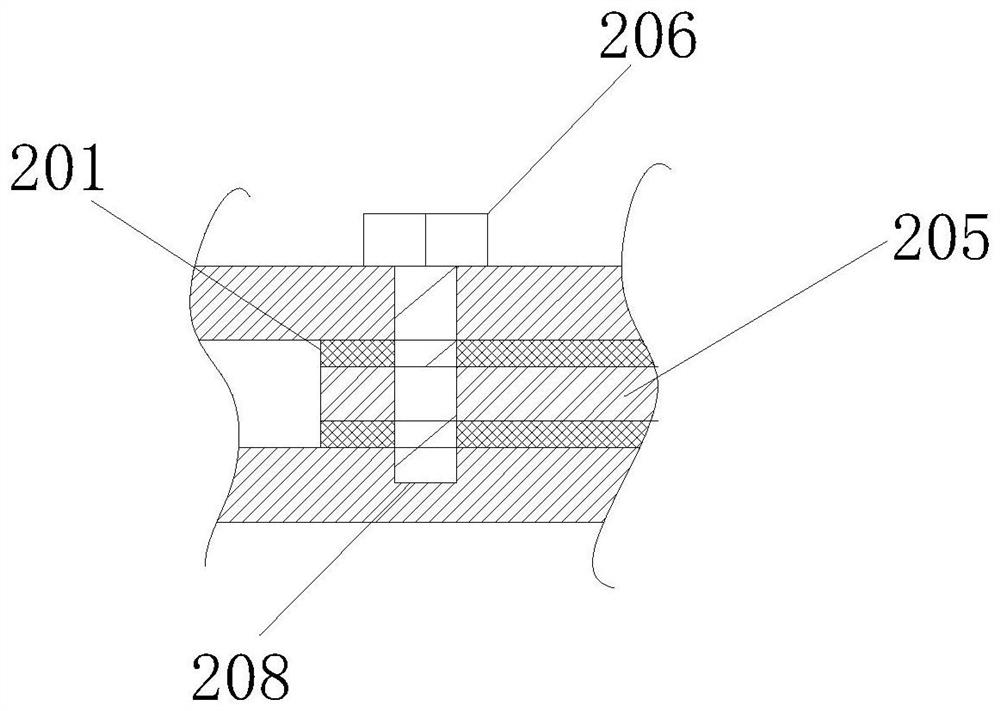

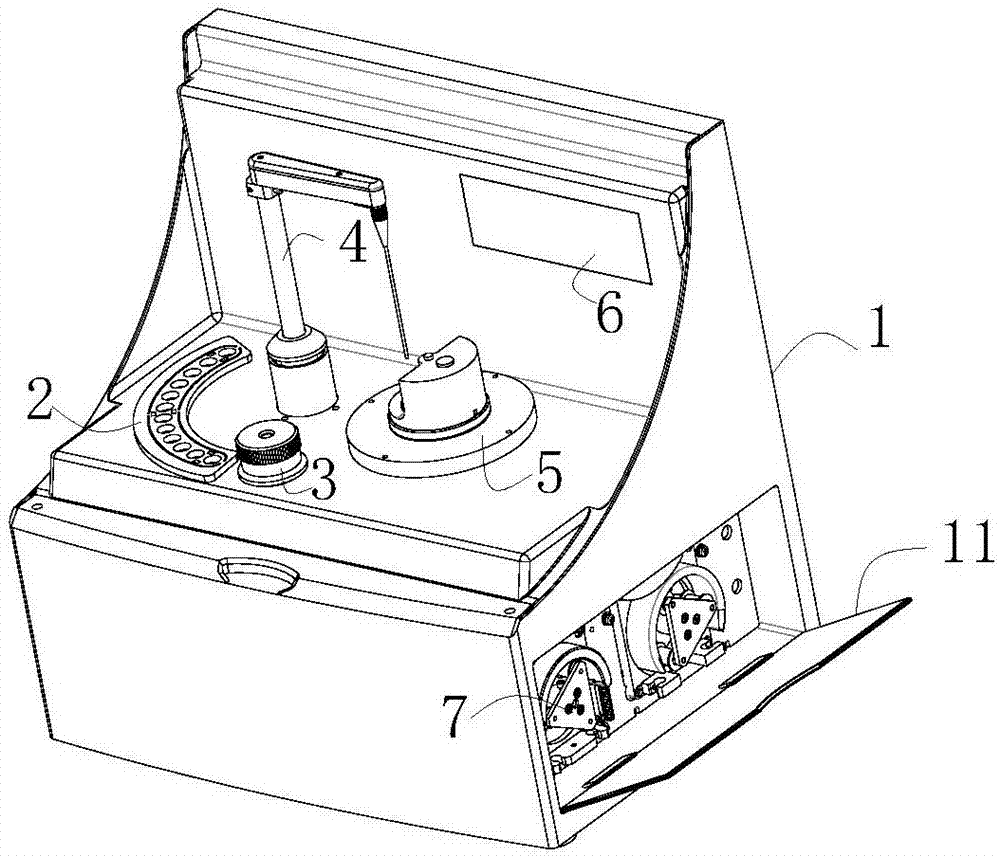

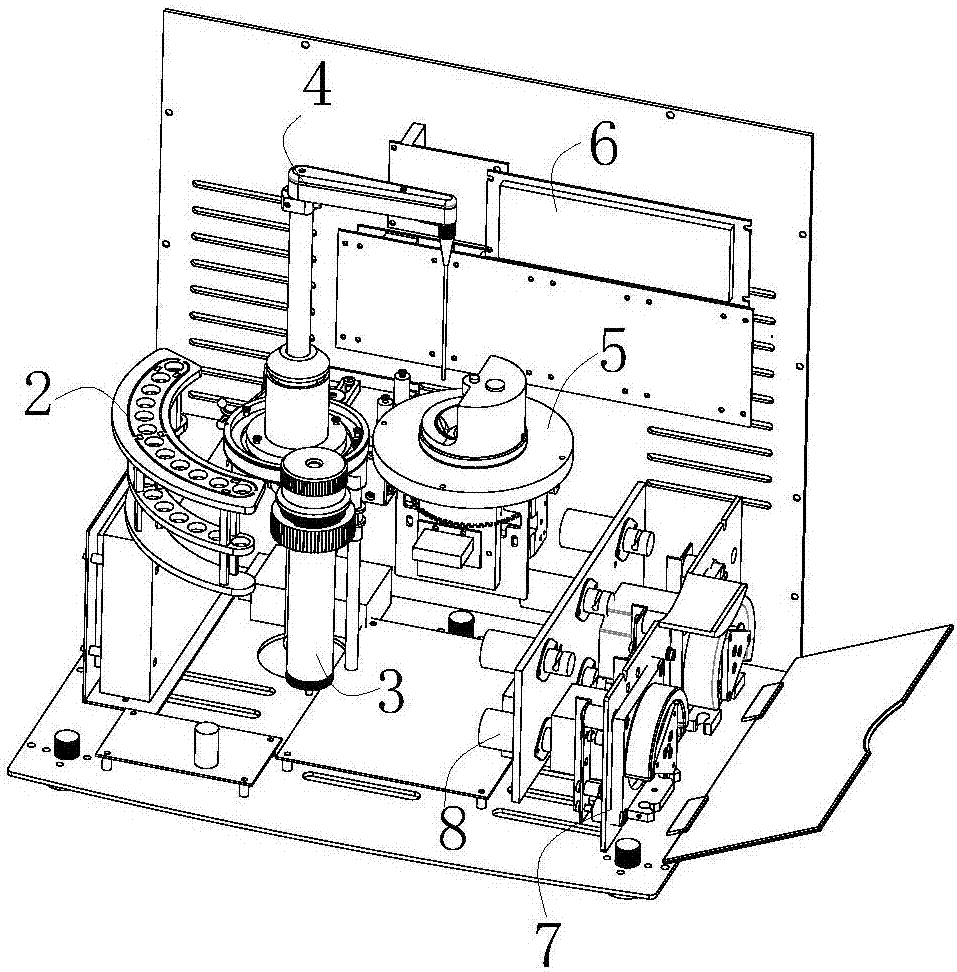

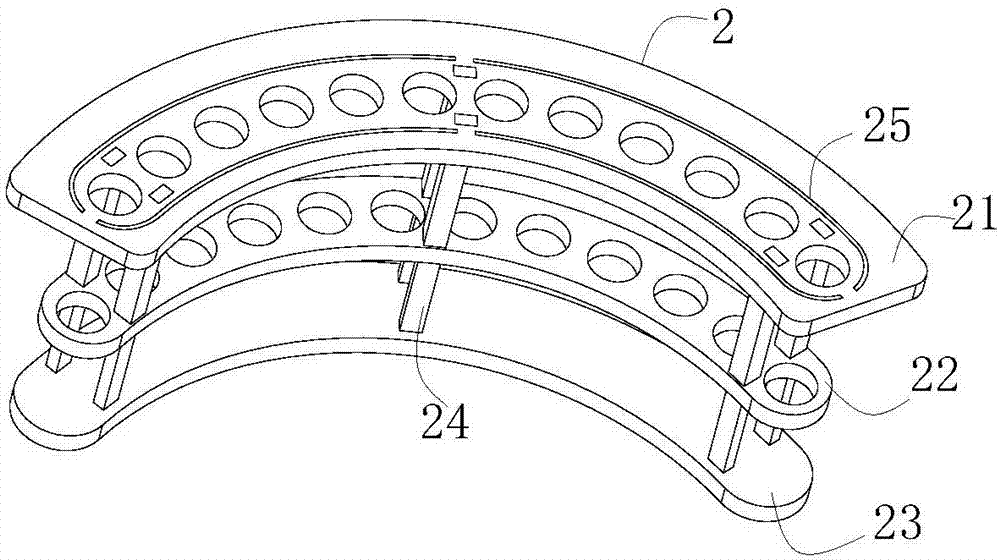

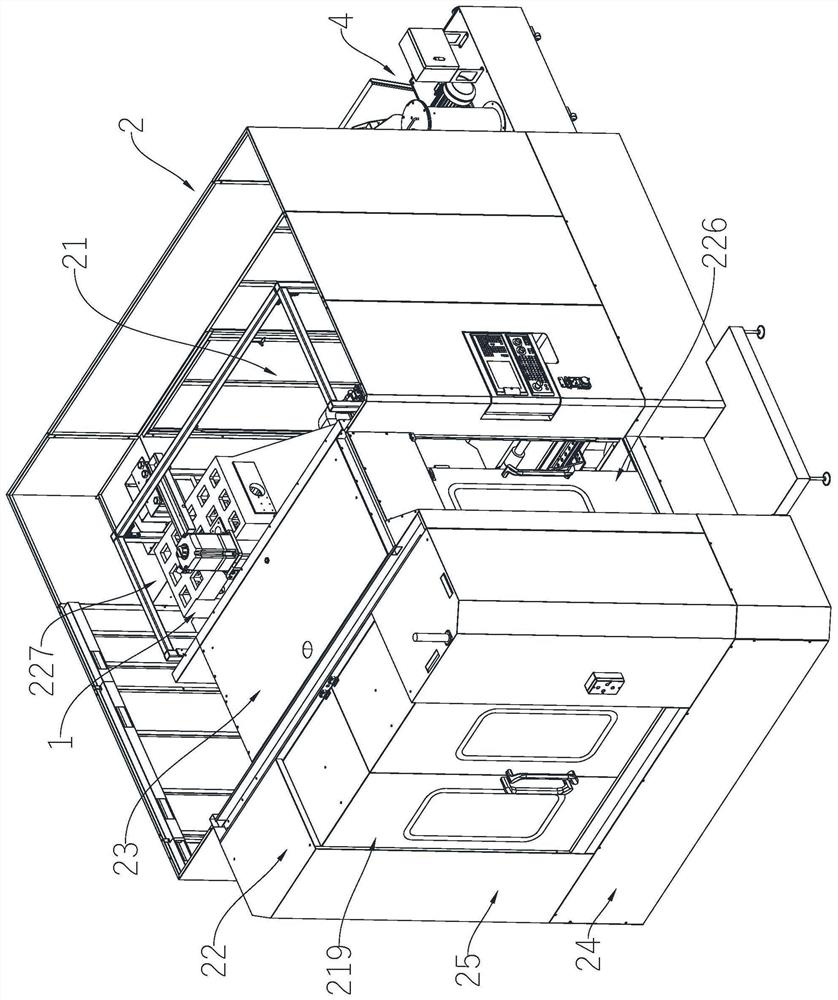

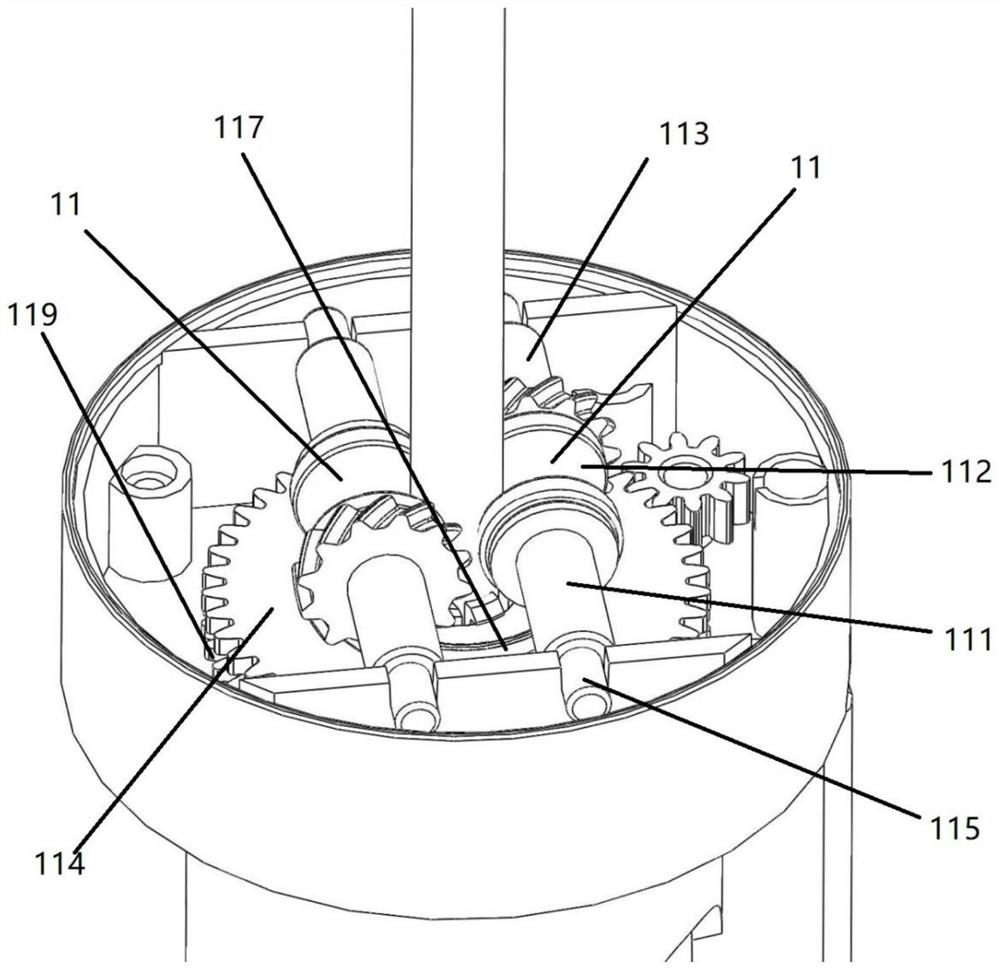

Device for testing blood rheology

ActiveCN107340206AConvenient and detachableEasy to assemble and disassembleFlow propertiesTest tubeMeasurement device

The invention relates to a device for testing blood rheology. The device includes a blood rheology instrument shell, the blood rheology instrument shell is divided into a vertical working surface and a horizontal working surface, the vertical working surface is provided with a LCD screen, the horizontal working surface is provided with a tube support frame, a cleaning device, a sampling device, a blood rheology measurement device, a LCD screen and a peristaltic pump power device; the cleaning device comprises a cleaning sleeve, a cleaning screw and a cleaning bottom cover arranged at the bottom of the cleaning sleeve, the sampling device comprises a sampling clamp device and a sampling power device, the sampling power device comprises a sampling rotary device and a sampling lifting device; the blood rheology measurement device comprises a blood rheology head main body, a blood rheology aluminum casing is installed in the vertical central part of the blood rheology head main body, the lower end of the blood rheology aluminum casing is provided with a jewel bearing seat, the blood rheology aluminum casing is provided with a coded disc arranged above the jewel bearing seat, the left side of the coded disc is provided with an electromagnetic coil, the right side of the coded disc is provided with a coded disc optocoupler, the upper end of the blood rheology head main body is provided with a blood rheology head support plate, and the blood rheology head support plate is provided with a blood rheology cone bowl.

Owner:TIANJIN HAIMAI MEDICAL TECH

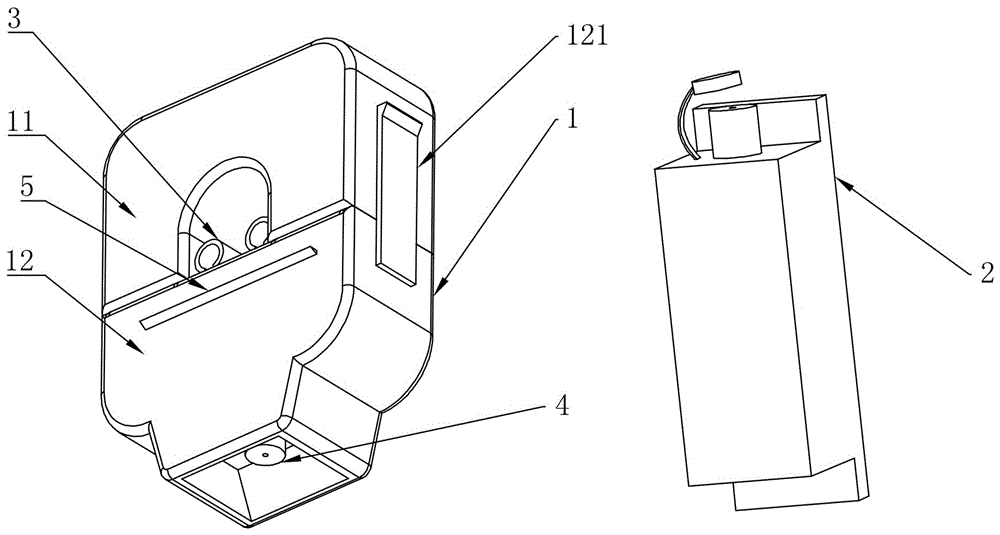

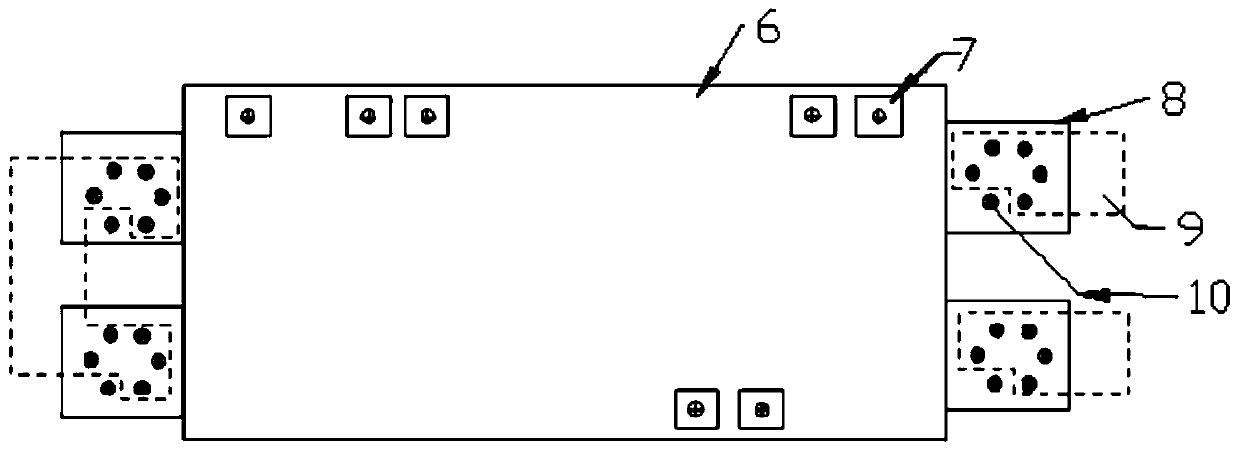

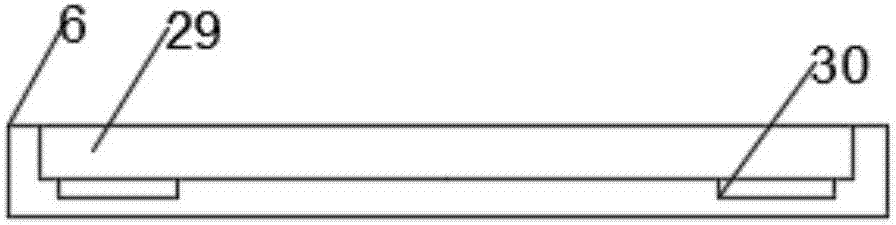

Television backboard processing center

PendingCN111791091ASimple structureReduce installation difficultyMetal working apparatusMaintainance and safety accessoriesMachine toolIndustrial engineering

The invention relates to a television backboard processing center. The television backboard processing center comprises a horizontal machine tool and a protective cover covering the outside of the horizontal machine tool, wherein the horizontal machine tool comprises a processing mechanism and a positioning mechanism, the processing mechanism comprises a rack, a main shaft frame and a main shaft seat which is arranged in the main shaft frame and can move in the Z-axis direction, a Y-axis screw rod is arranged on the front side of the rack, and a Y-axis screw rod nut which is matched with the Y-axis screw rod and can be clamped on the Y-axis screw rod is arranged on one side of the main shaft frame; the positioning mechanism comprises an installation plate which can rotate in the horizontaland vertical directions; and the protective cover comprises a machine tool cabin, a material changing cabin and a processing cabin, the side walls of the material changing cabin and the processing cabin correspondingly comprise coaming boards and wall boards installed on the upper parts of the coaming boards, a bottom plate is installed on the inner joints of the coaming boards and the wall boards, the wall boards and the bottom plate are sealed and connected in a clamped mode, and the wall boards are detachably connected with the coaming boards. According to the television backboard processing center, the whole structure of the horizontal machine tool is simplified, the installation difficulty is reduced, and the use cost is reduced.

Owner:江苏普拉迪数控科技有限公司

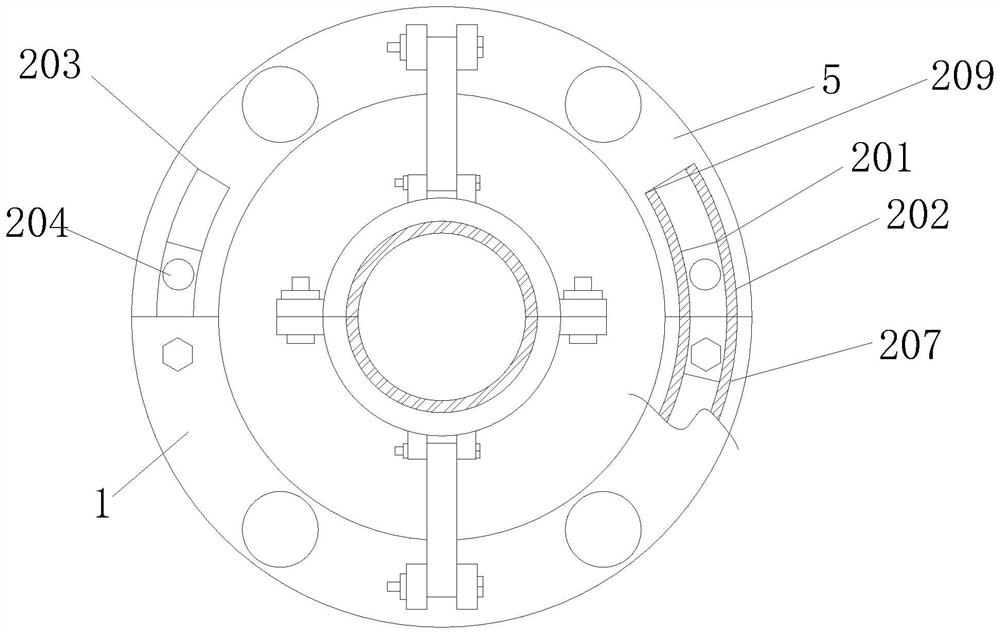

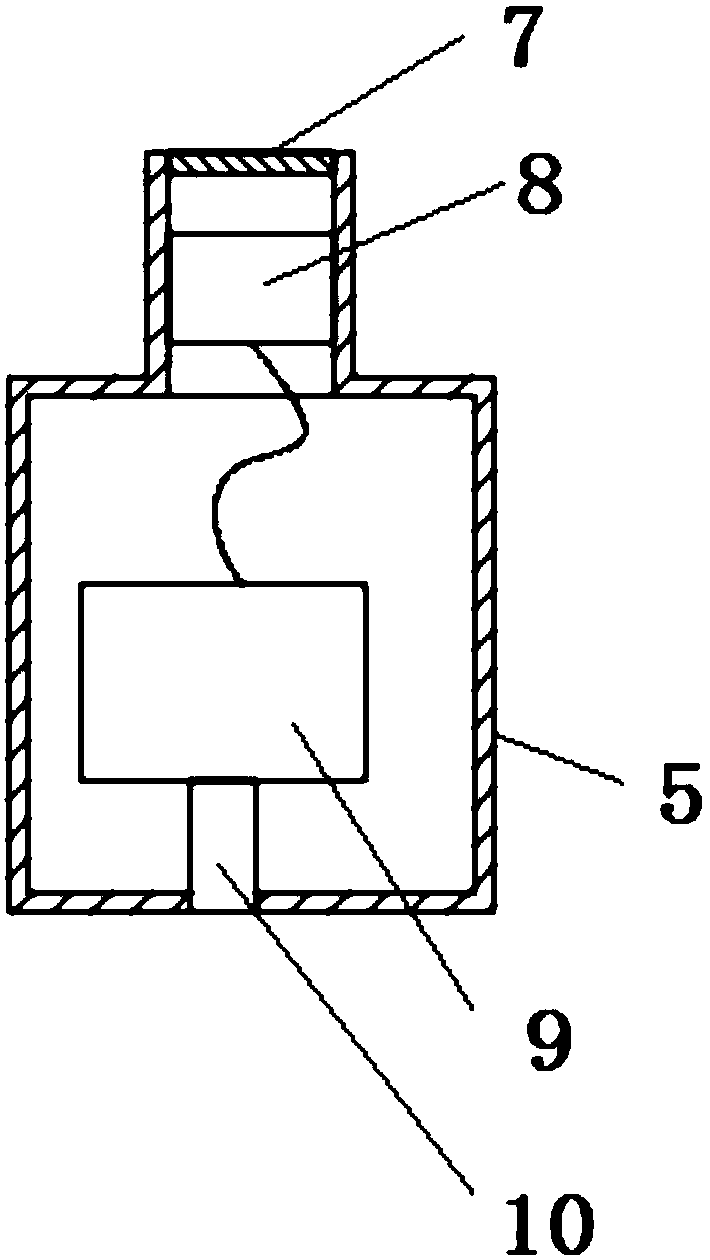

Current transformer device capable of being installed fast in electrified mode

ActiveCN105869851AEfficient disassemblyRealize disassemblyTransformers/reacts mounting/support/suspensionTransformersConductor CoilInstrument transformer

The invention discloses a current transformer device capable of being installed fast in an electrified mode. The current transformer device comprises a transformer bracket and a transformer. The transformer bracket comprises a mechanical part, an insulating part and an operation part. The mechanical part comprises a first connecting rod, an upper die and a lower die, wherein the first connecting rod is sleeved with the upper die and the lower die. The transformer comprises an induction body inducting with an external cable and a measuring body for measuring the induction current value. The inducting body and the measuring body are connected through a wire. The inducting body comprises a first shell, a second shell capable of being detachably connected with the first shell, and a winding arranged in the first shell and the second shell. According to the current transformer device capable of being installed fast in the electrified mode, the first shell and the second shell are arranged on the transformer, the mechanical part, the insulating part and the operation part are arranged, and therefore the current transformer can be installed fast and effectively in the electrified mode.

Owner:STATE GRID CORP OF CHINA +2

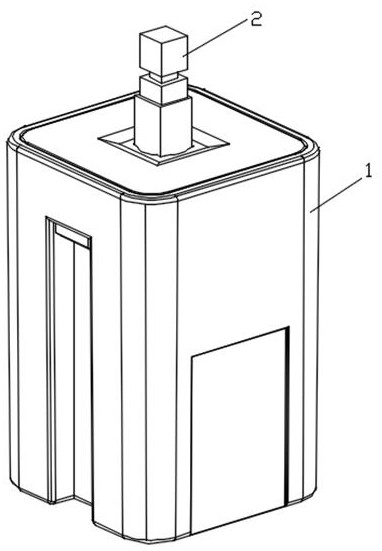

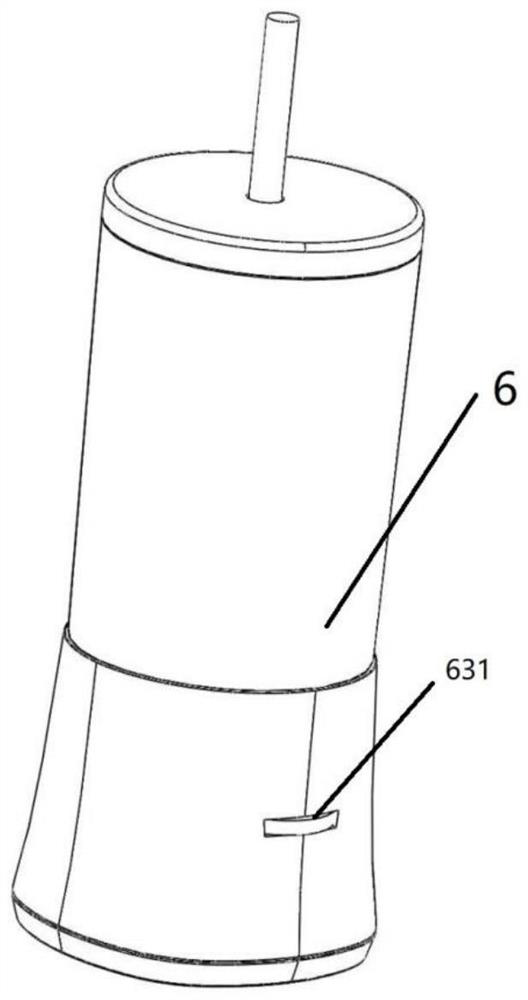

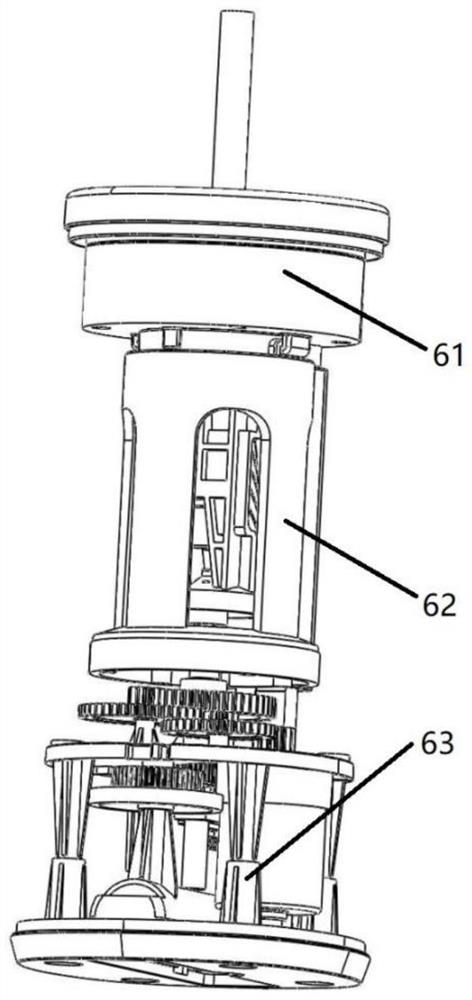

Air purifier

InactiveCN107559987AImprove performanceConvenient and detachableSpace heating and ventilation safety systemsLighting and heating apparatusAir filterAir purifiers

The invention discloses an air purifier. The air purifier comprises a shell, a movable front door and an purification part, wherein air inlets are formed in two sides of the shell; an air outlet is formed in the upper part of the shell; the upper part of the shell can be opened; the movable front door is arranged on the front side of the shell; a guide part is arranged in the front side of the shell; sliding parts are arranged on two sides of the inside of the shell and are slidably disposed in the guide part; a hinge part is arranged at the lower part of the shell and is connected with the movable front door; the purification part is arranged on one side of the movable front door in the shell. According to the air purifier, the air flows into the shell from two sides, so that the air admission amount is increased; the air filtering efficiency is improved; the movable front door is arranged on the front side of the shell, so that the disassembly of a filter screen in the purification part is facilitated; silica gel sealing strips are arranged on four sides of the movable front door; the performance of the overall air purifier is improved.

Owner:ANHUI LEJIN ENVIRONMENT TECH CO LTD

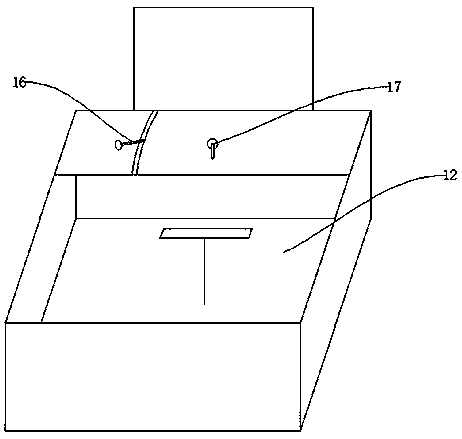

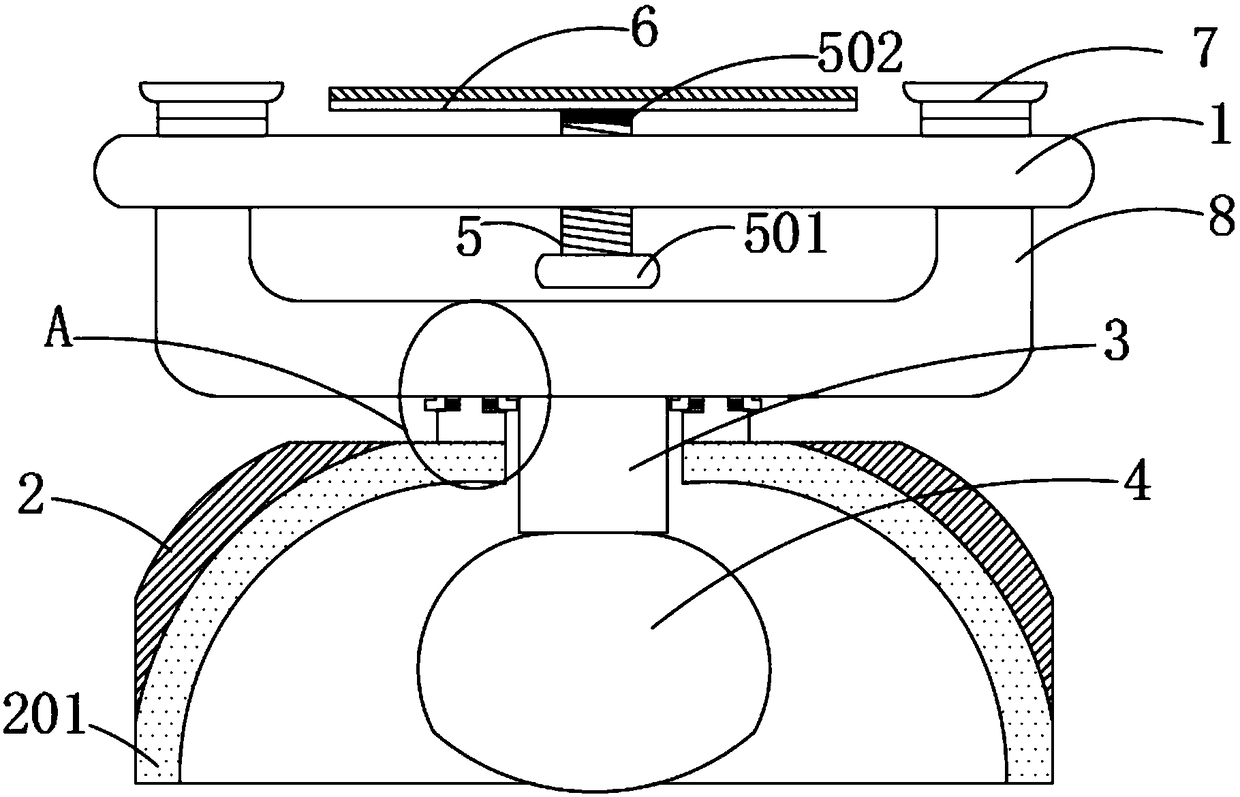

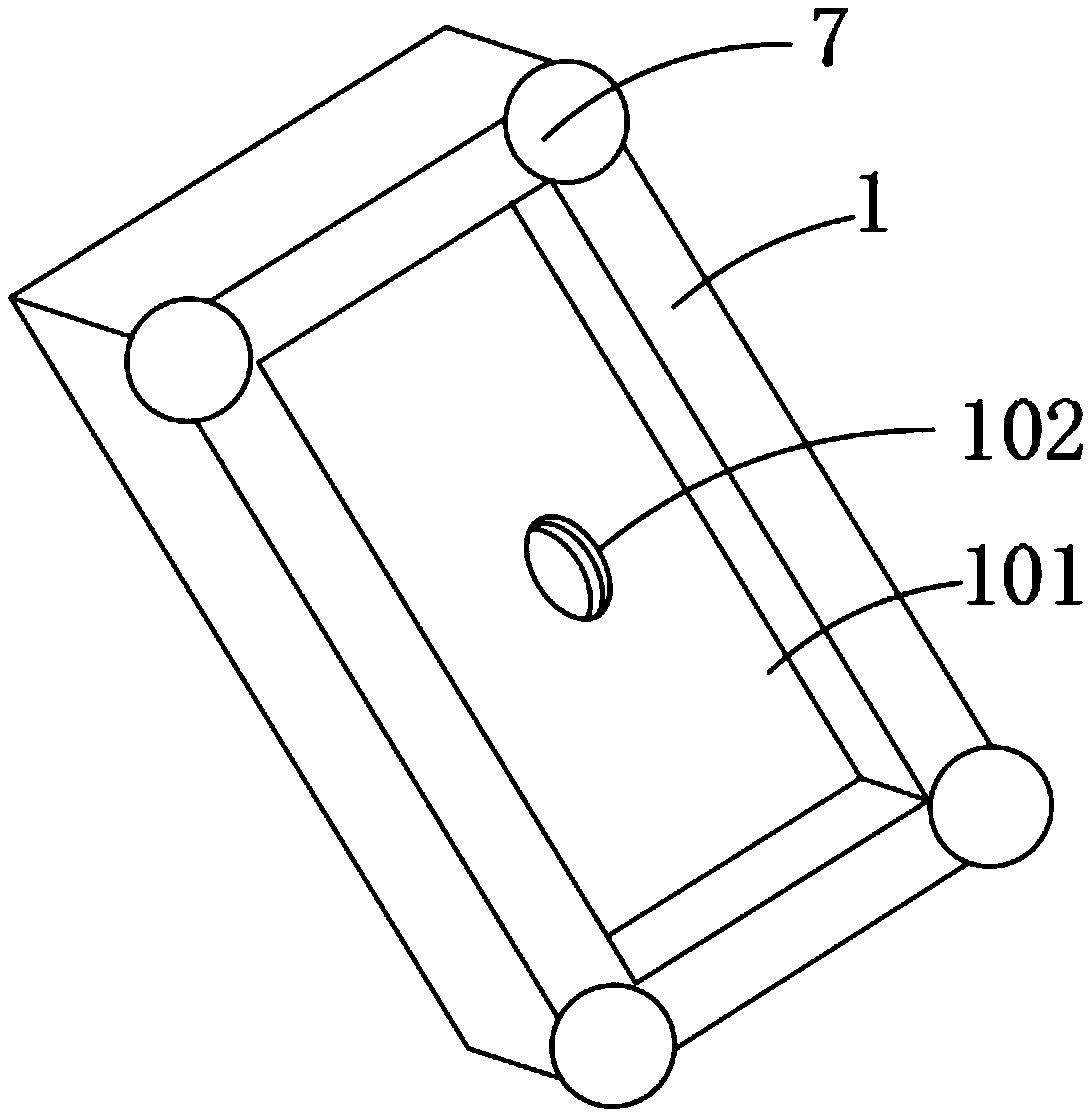

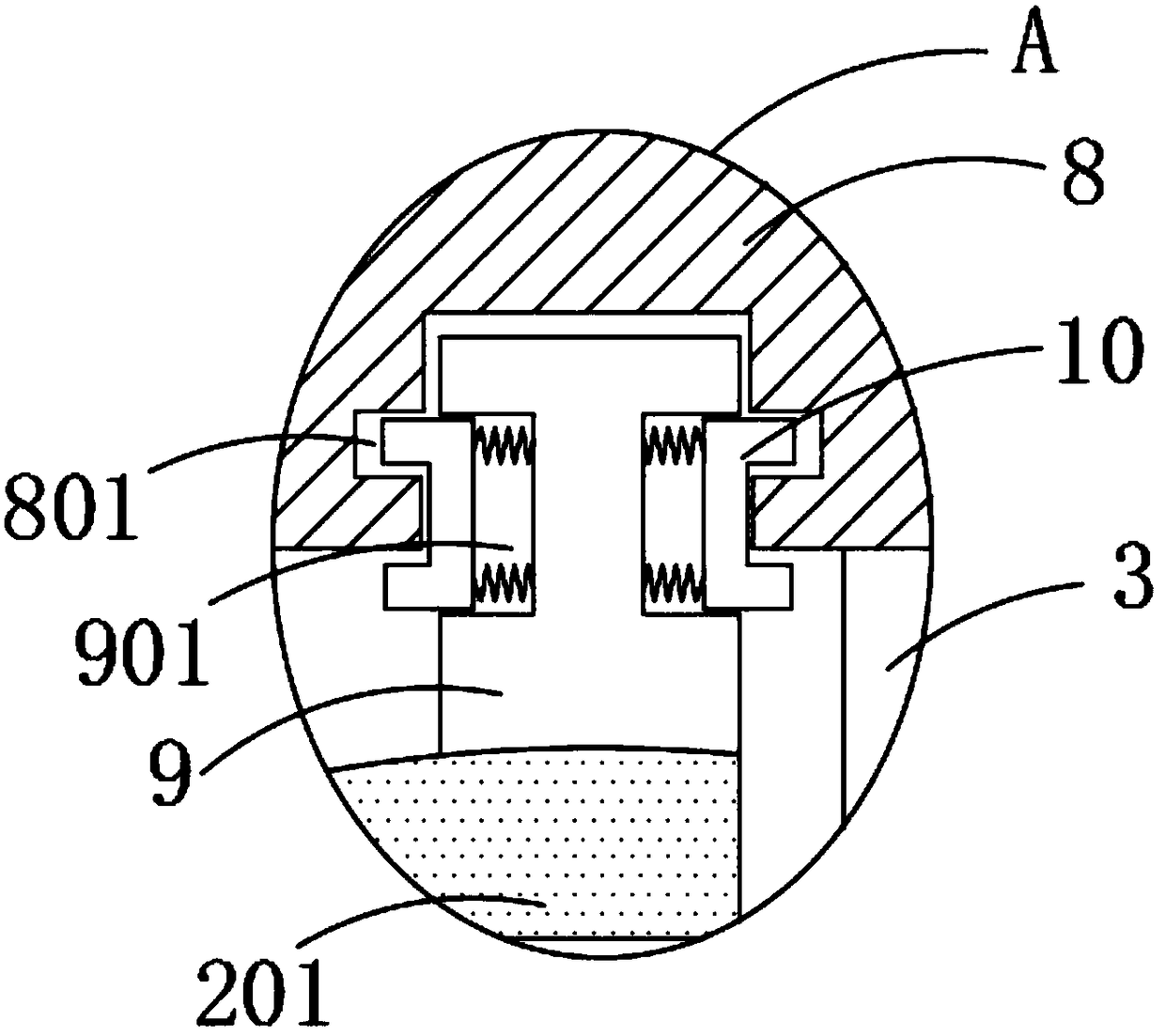

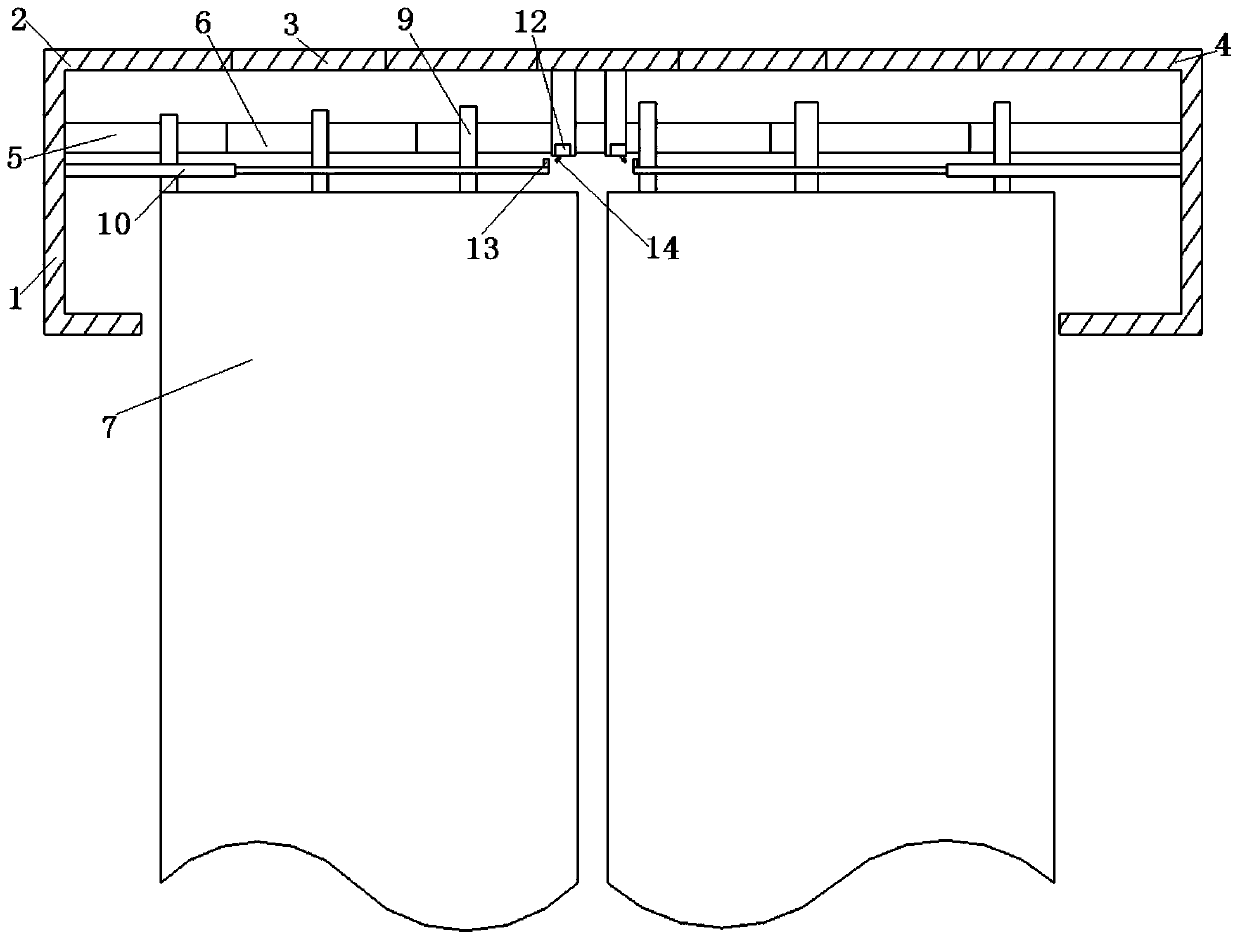

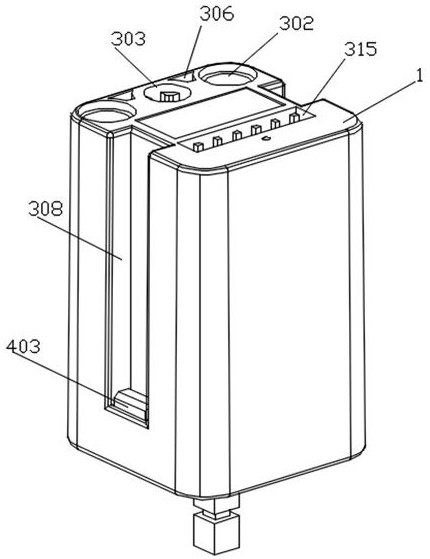

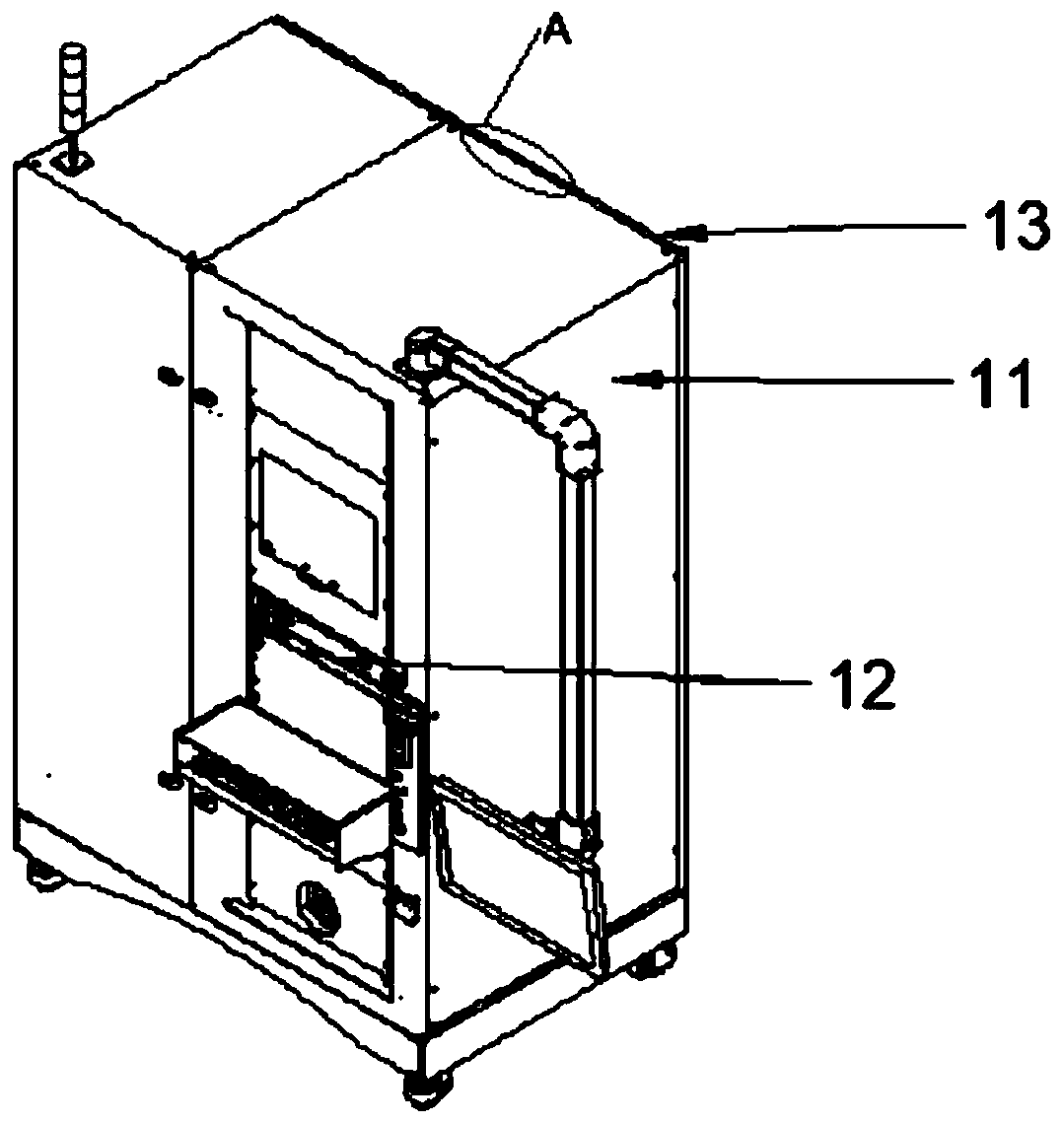

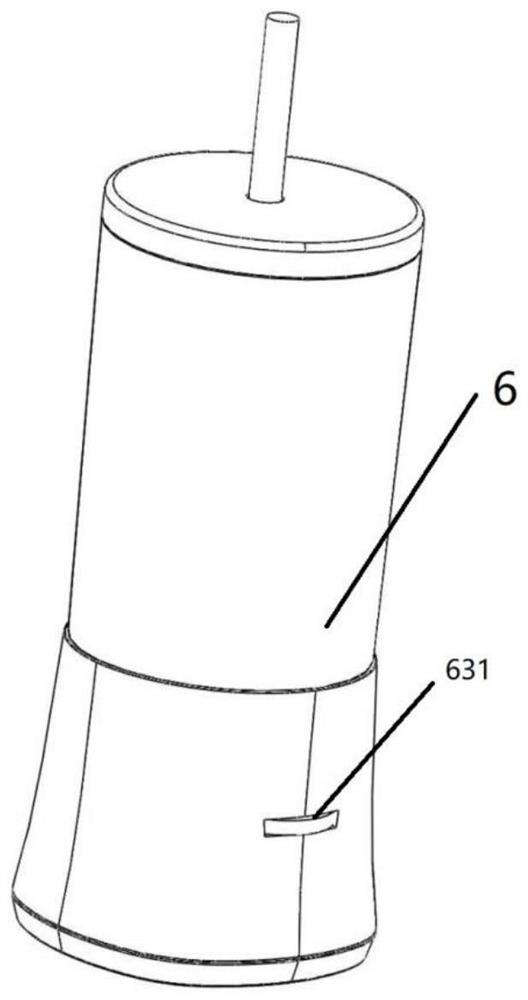

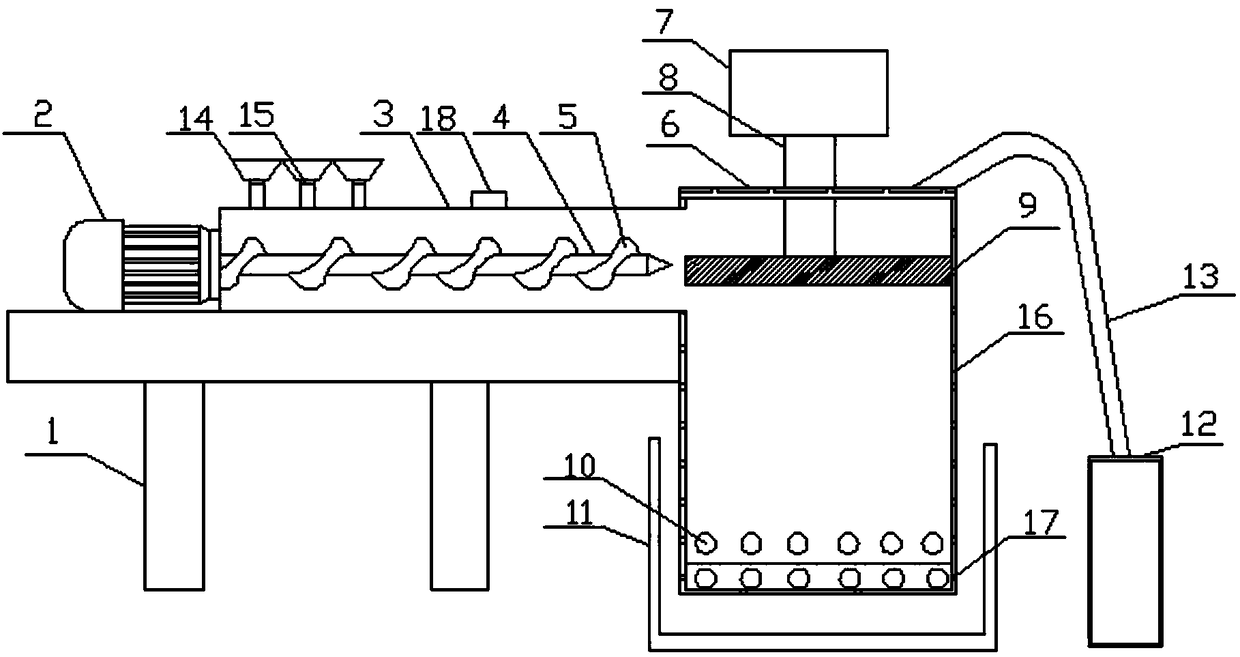

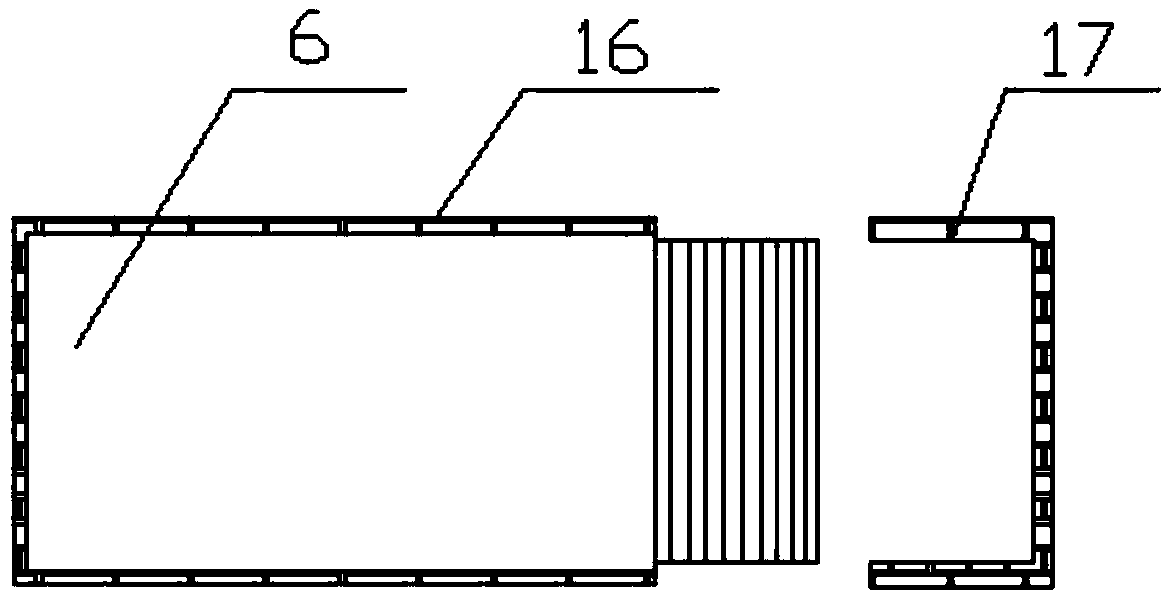

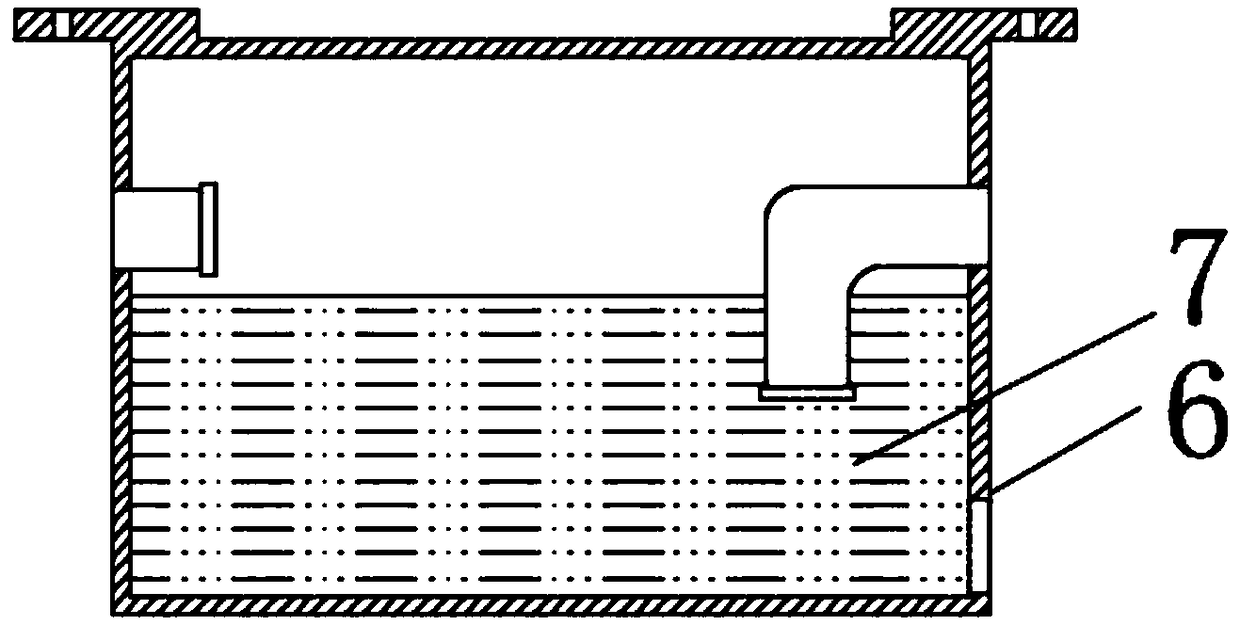

Steaming stove for steaming food

PendingCN108518704AConvenient and detachablePromote refluxLighting and heating apparatusStove/ranges for heating waterCombustion chamberMaterial supply

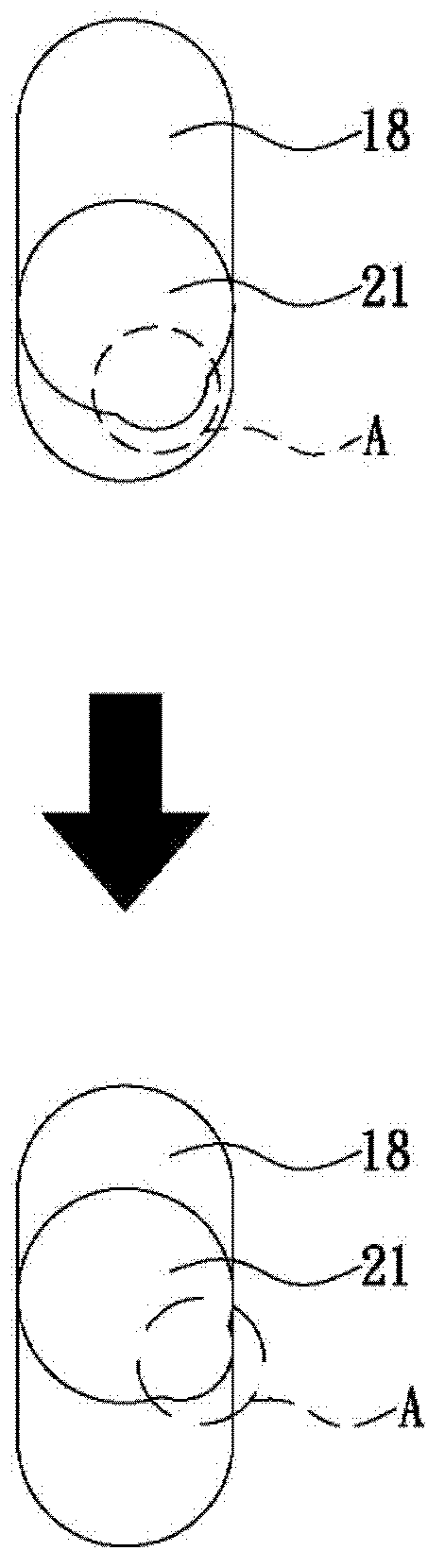

The invention discloses a steaming stove for steaming food. The steaming stove for steaming the food comprises a material supply assembly arranged on the left side of a box body (1), an ash discharging box (2), a combustion chamber (3) and a water tank (12), wherein the ash discharging box (2), the combustion chamber (3) and the water tank (12) are arranged on the right side of the box body (1) from bottom to top. The steaming stove for steaming the food is characterized in that the combustion chamber (3) is installed on the upper portion of the ash discharging box (2), a combustion inner cylinder (4) is installed in the combustion chamber (3), the combustion inner cylinder (4) is provided with holes (5), a baffle (6) is arranged between the combustion chamber (3) and the combustion innercylinder (4), a material falling bin (8) is installed on the upper portion of the combustion chamber (3), the water tank (12) is installed on the top of the material falling bin (8), a plurality of heating pipelines (11) are arranged in the water tank (12), and a food steamer (14) is detachably installed on the upper portion of the water tank (12). The material supply assembly comprises a spiral material supply pipe (22) and a feeding cylinder (18), wherein one end of the spiral material supply pipe (22) communicates with the bottom of the feeding cylinder (18), and the other end of the spiralmaterial supply pipe (22) communicates with the material falling bin (8). The steaming stove for steaming the food is efficient, good in quality, simple in structure and suitable for use and popularization for food steaming.

Owner:贵州安顺惠烽科技发展有限公司

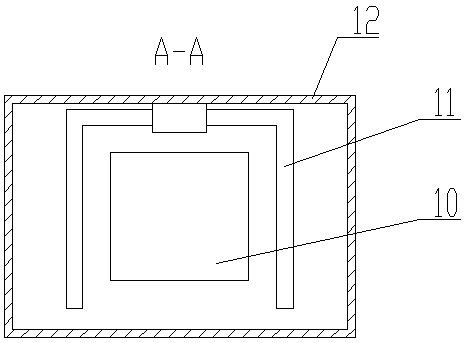

Semiconductor device test fixture and test box body

PendingCN110954802AEasy to useEasy to disassembleMeasurement instrument housingIndividual semiconductor device testingEpoxyDevice material

A semiconductor device test fixture disclosed by the present invention comprises an epoxy plate, a first signal probe, a first connecting end, a second signal probe and a second connecting end, wherein the first connecting end is arranged on one side of the epoxy plate, the position, close to the first connecting end, of the top of the epoxy plate is connected with the first signal probe through aconnecting column body, and the second signal probe is further arranged at the bottom of the epoxy plate, and a second connecting end is arranged at the position, at one side of the second signal probe, of the bottom of the epoxy plate. The invention also discloses a semiconductor test box body. When the test fixture is used, the first signal probe of the test fixture is connected with a third connecting point, the second connecting end is connected with a second connecting point, and the second signal probe is connected with the first connecting point of a tested piece, so that the tested piece is connected with the test fixture. When the test fixture is used, the test fixture is convenient to detect and use, is time-saving and labor-saving, and is convenient to disassemble.

Owner:HEFEI KEWELL POWER SYST CO LTD

Double-lug cup

The invention discloses a double-lug cup. In order to effectively expand functions of a cup and realize diversification of the functions of the cup, a handle of an original cup is designed to be two detachable handles, and the handles can be used as a fork and a ladle. The problem of a single function of a traditional cup is solved.

Owner:重庆韵源科技有限公司

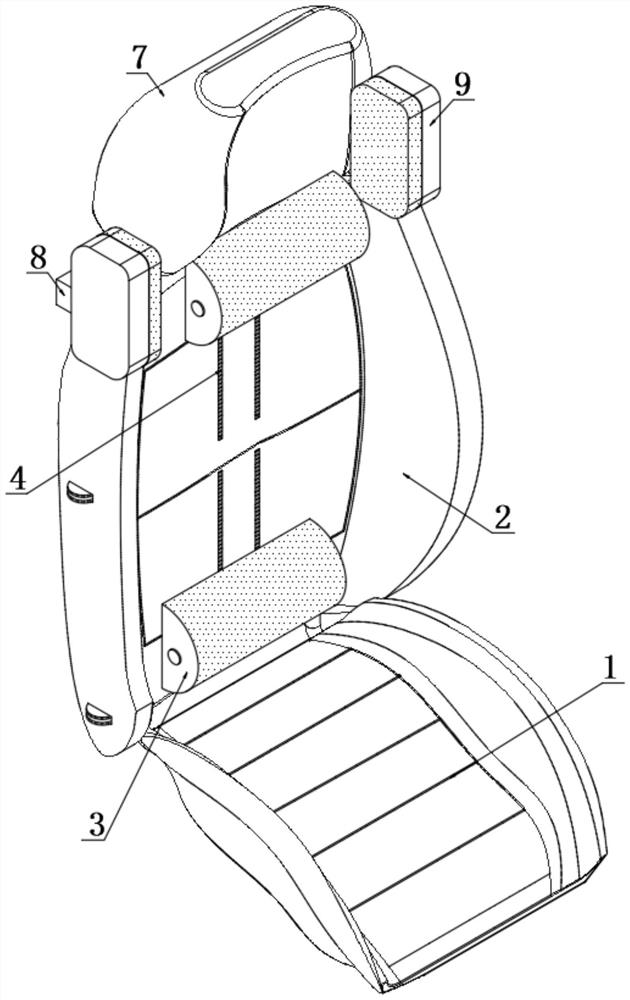

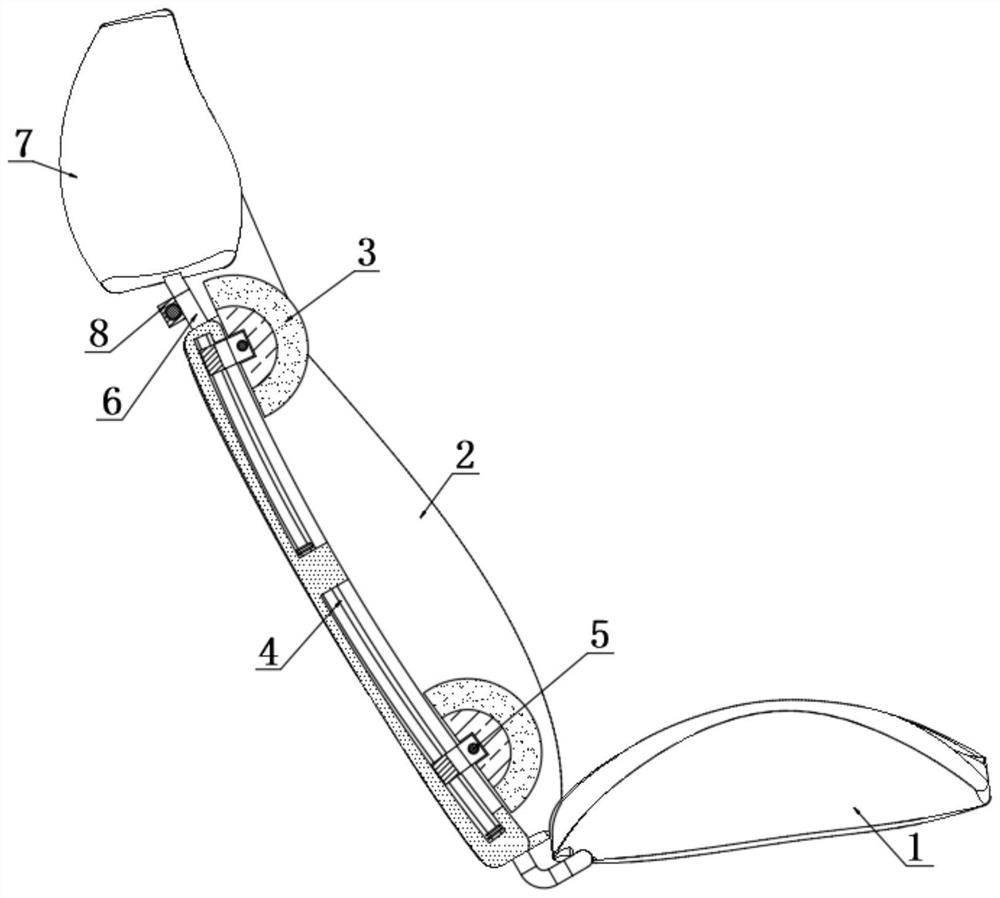

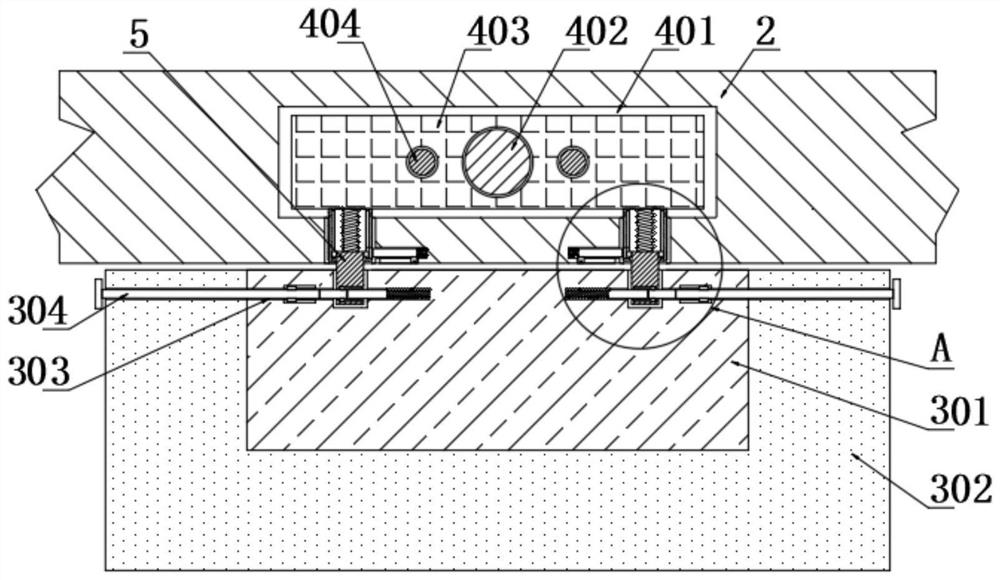

Safe automobile seat with high comfort and using method thereof

ActiveCN114655095AEasy to slideConvenient and detachableInternal combustion piston enginesBack restsCar seatCushion

The invention discloses a high-comfort safety automobile seat and a using method thereof.The high-comfort safety automobile seat comprises a cushion body and a backrest body, back cushion mechanisms are arranged at the top and the bottom of the backrest body, and sliding mechanisms are arranged at the top and the bottom of the backrest body; the back cushion mechanism comprises a cushion block, a soft cushion, two pressing grooves, two pressing blocks, two sliding grooves, two first compression springs, two sliding rods and a connecting groove, the two sliding grooves are formed in the two sides of the cushion block, and the sliding mechanism comprises a sliding groove, a lead screw, a sliding block, two limiting columns, two synchronous wheels, a synchronous belt, a plurality of rotating grooves and a rotating shaft. The synchronous belt is arranged between the two synchronous wheels, and two connecting mechanisms are arranged on one side of the sliding block. The arrangement mode that the back cushion mechanism, the sliding mechanism and the connecting mechanism are matched is utilized, the cushion block and the backrest body can be detached conveniently, sliding of the soft cushion is facilitated through the sliding block, and the backrest is suitable for supporting waists and necks of passengers of different heights conveniently.

Owner:HIGHER TECH CO LTD

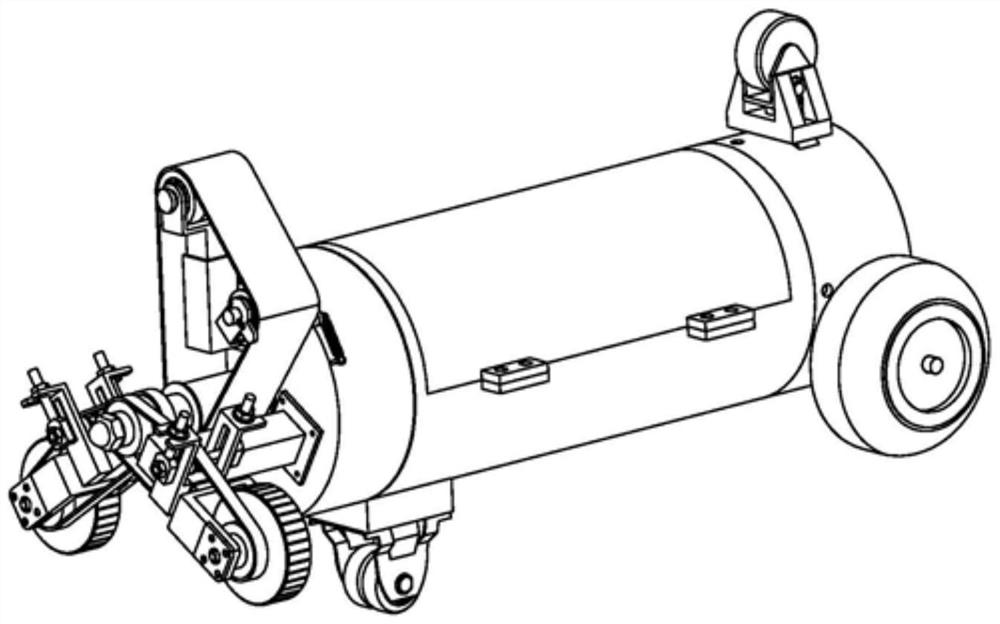

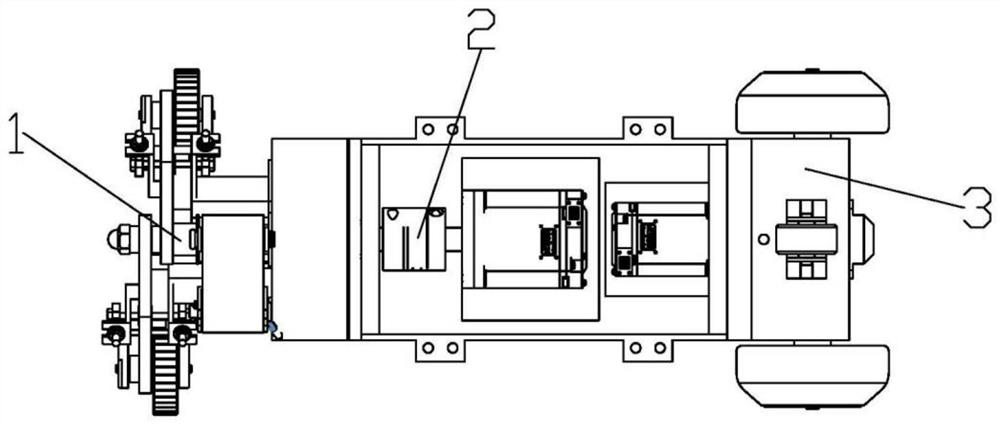

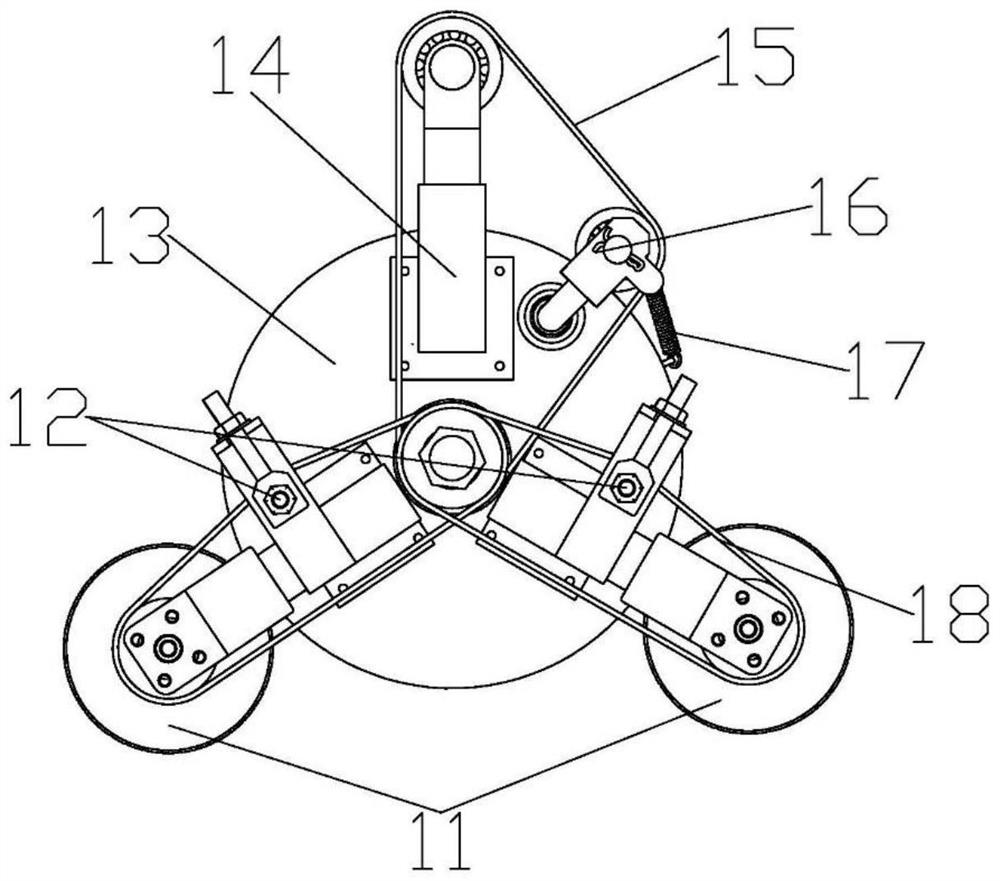

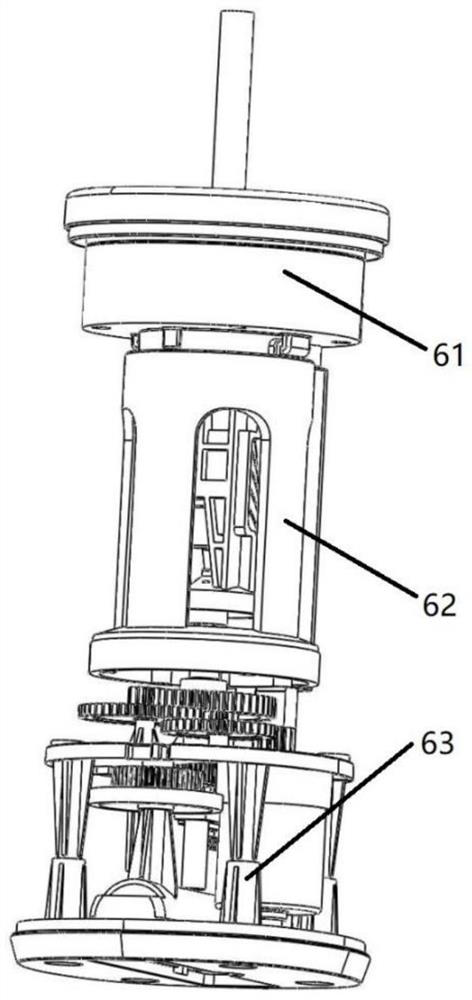

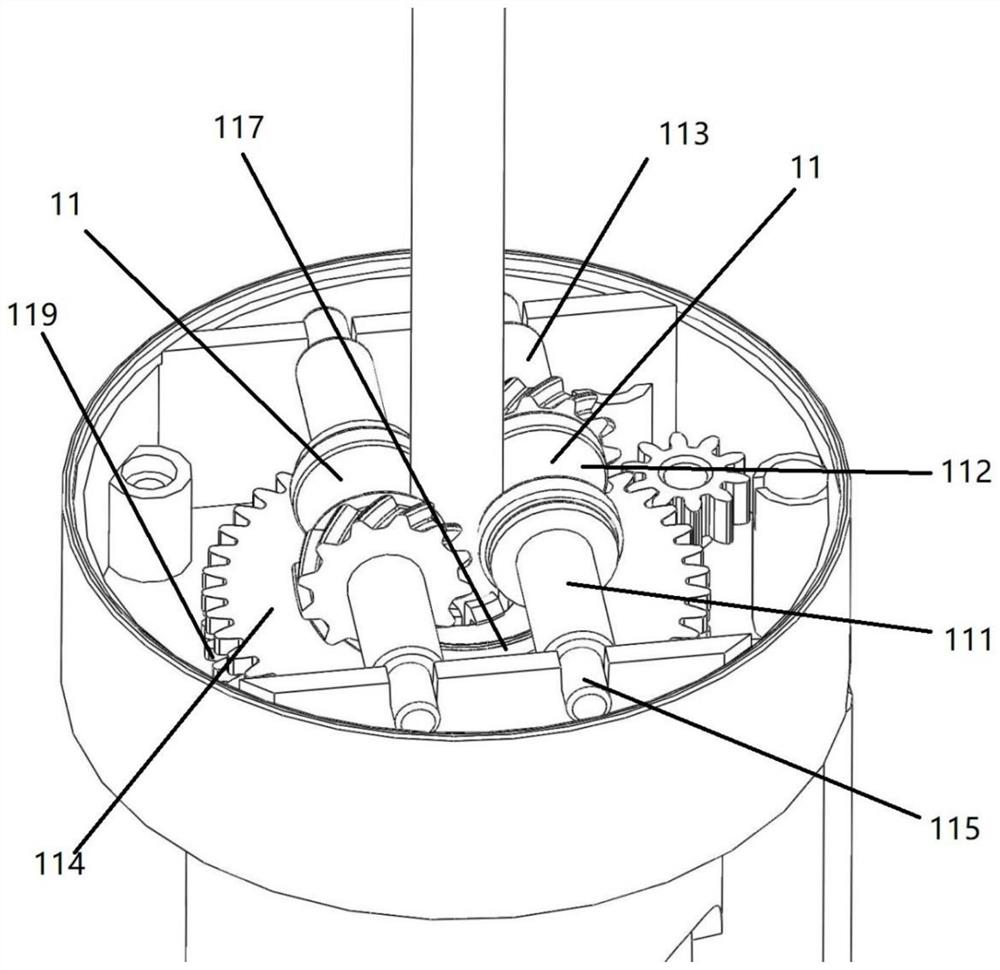

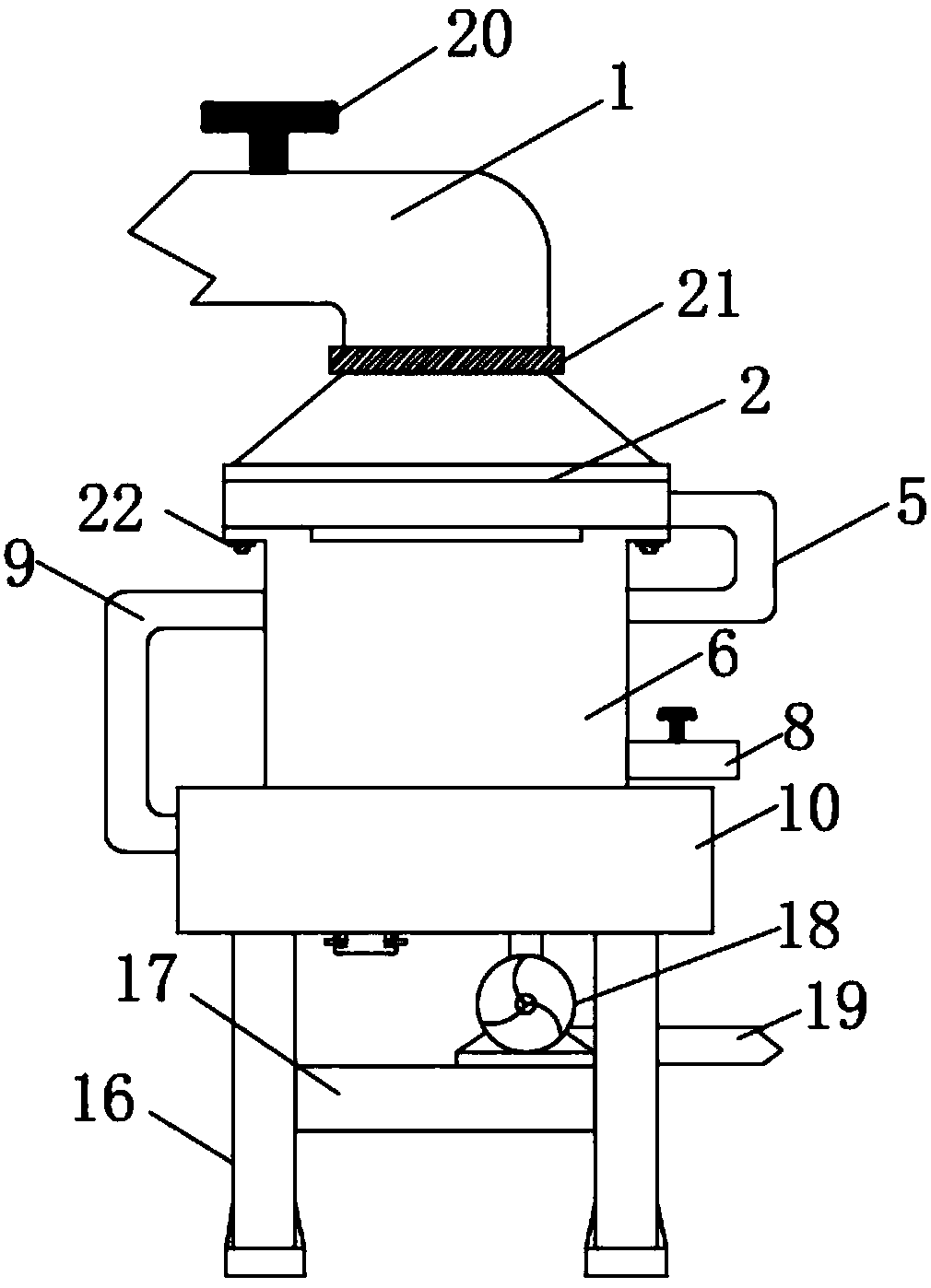

Walking polishing device for inner wall of small-diameter cylinder

ActiveCN114290199AAdapt to deformationAdapt to the problem of poor roundnessPolishing machinesGrinding drivesPolishing

The invention provides a walking polishing device for the inner wall of a small-diameter cylinder. The walking polishing device comprises a rotary polishing part, a rotary driving mechanism and a walking driving structure. The front end of the rotary driving mechanism is provided with the rotary polishing part, and the rear end is provided with the walking driving structure; at least one polishing wheel is installed on the rotary polishing component through a polishing wheel fixing mechanism, and the polishing wheel fixing mechanism can rotate relative to the rotary driving mechanism along the center position of the rotary polishing component. In-cylinder walking and rotary polishing can be executed through rotary driving and walking driving correspondingly, and practicability and universality are high; the problems of deformation and poor roundness caused by machining precision difference of the inner wall of the barrel can be solved; and the polishing device is convenient to mount and detachable, and can be used for polishing the inner walls of barrel products of different specifications or materials.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

Pencil sharpener

The invention discloses a pencil sharpener which comprises an automatic pencil feeding structure, a self-starting structure, a knife rest, a gear adjusting structure, a pencil point protecting structure and a detachable pencil sharpening frame. The detachable pencil sharpening frame comprises an upper portion, a middle portion and a lower portion, the automatic pencil feeding structure is arranged on the upper portion, the knife rest is arranged in the middle portion, the gear adjusting structure is arranged on the lower portion, and the self-starting structure and the pencil point protecting structure penetrate through the upper portion, the middle portion and the lower portion. The pencil sharpener is simple in structure, convenient to operate, relatively low in cost and long in service life.

Owner:NINGBO TIANTIAN STATIONERY CO LTD

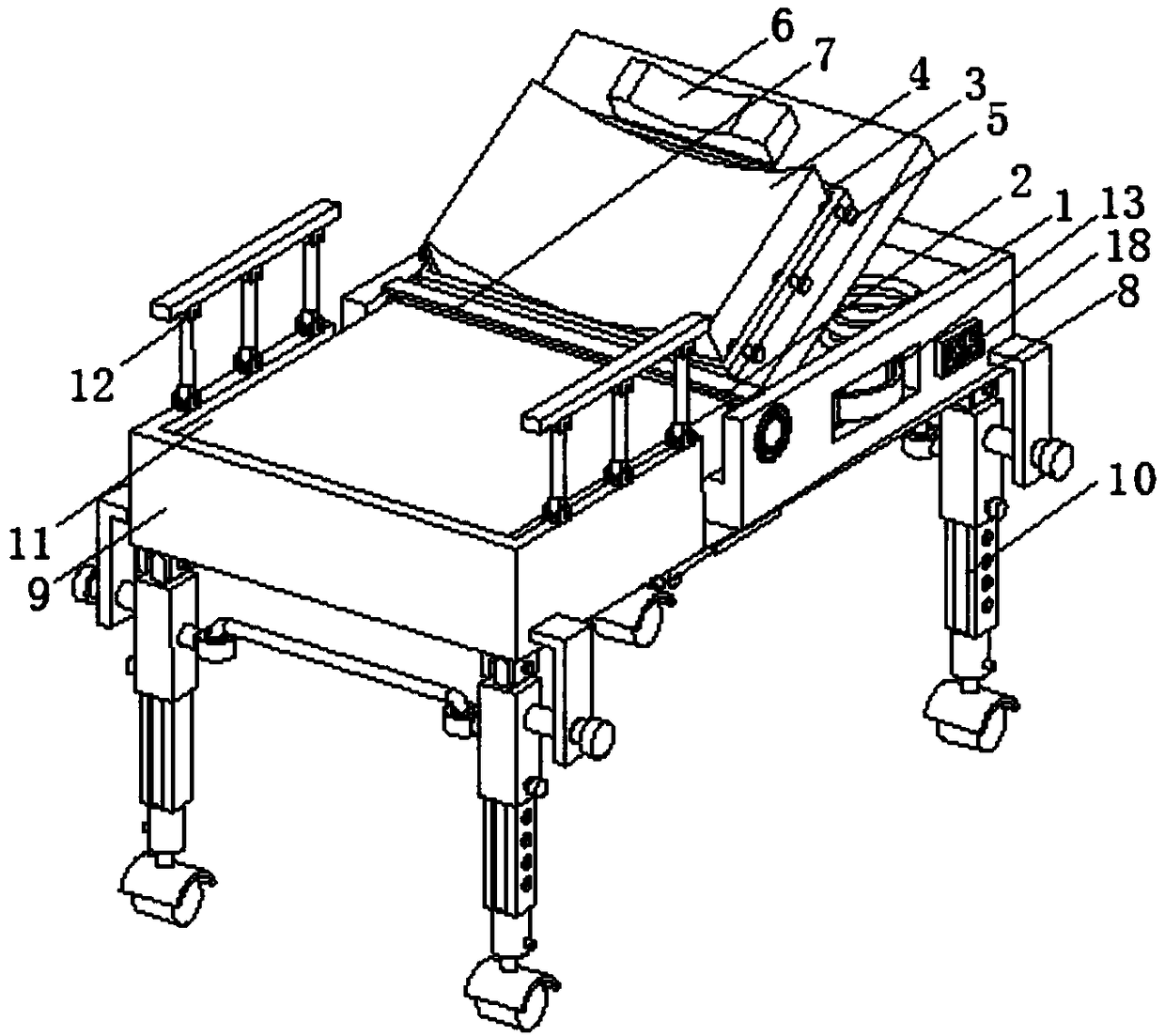

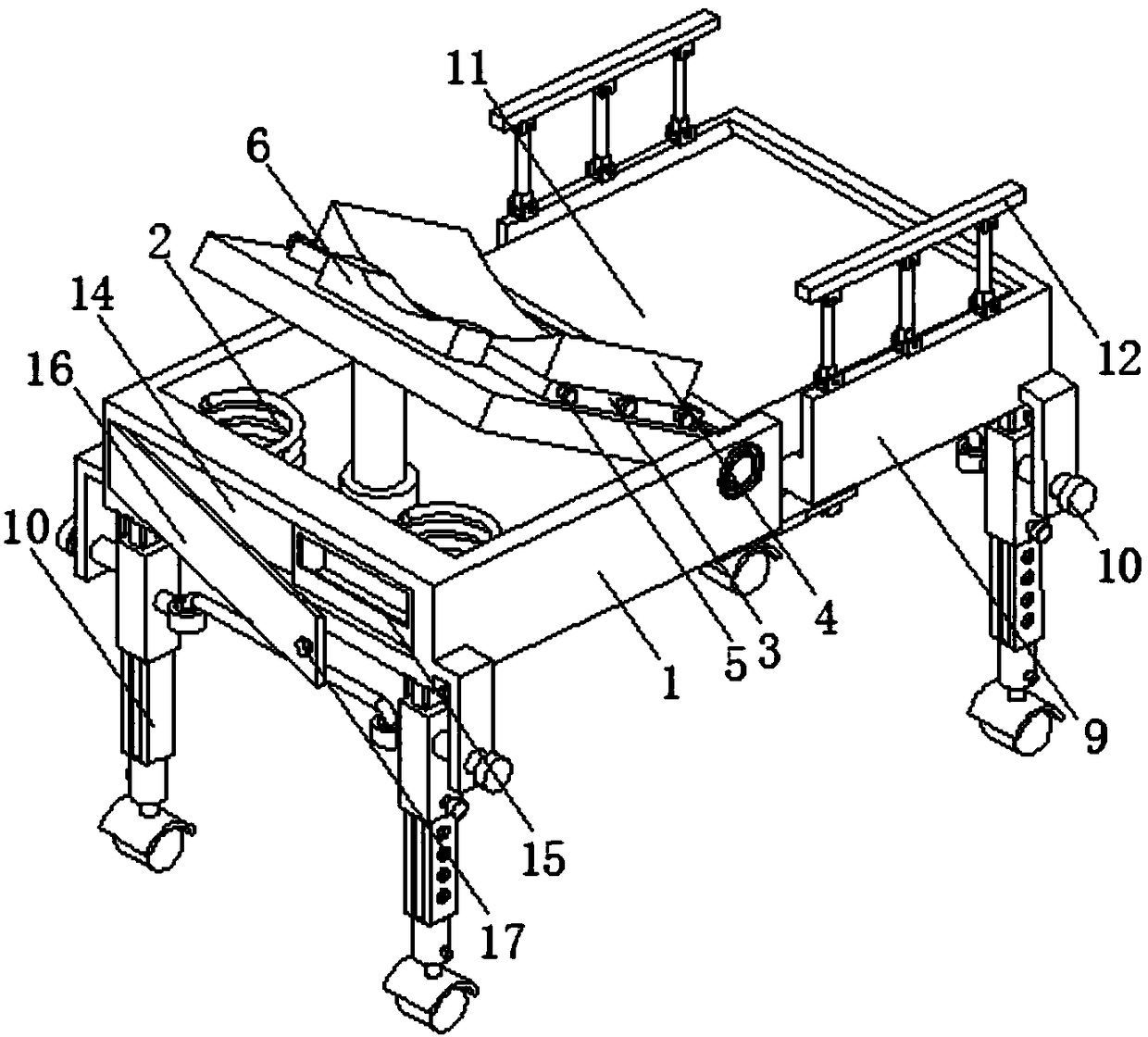

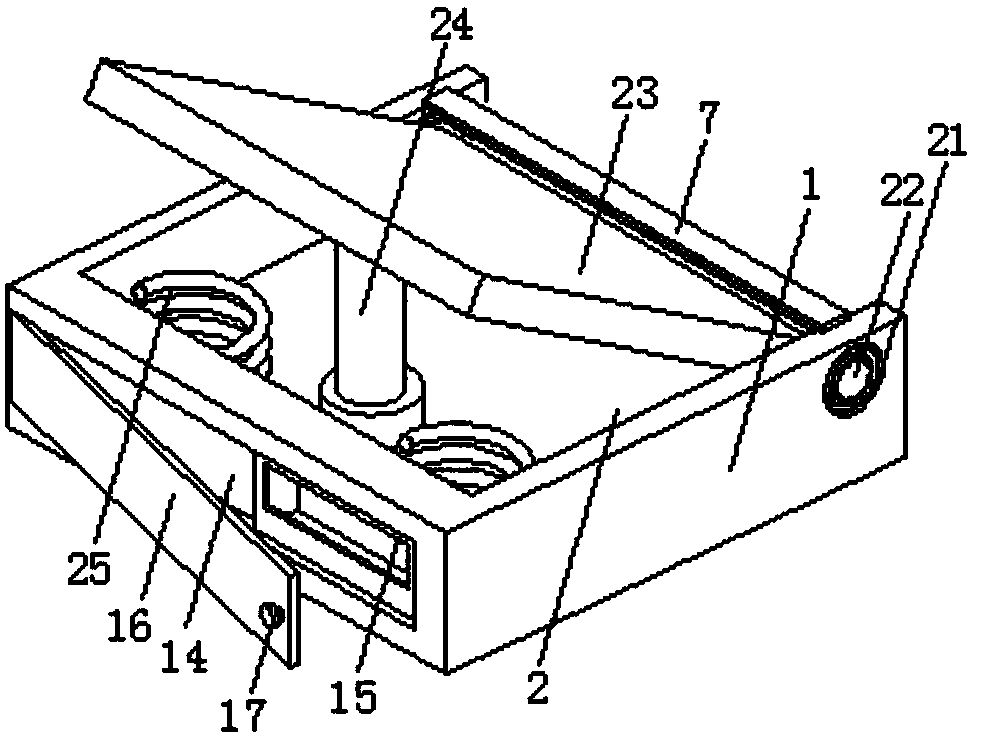

Obstetric table with split structure

InactiveCN107320276AEasy to fixEasy to disassembleOperating tablesMedical transportInsertion stentMechanical engineering

The invention discloses an obstetric table with a split structure. The obstetric table with the split structure comprises a bed board, a bracket, movable wheels and a locating device, wherein the bed board comprises a first bed board body and a second bed board body, and the first bed board body and the second bed board body are connected with each other through a base hinge; the bracket comprises an adjusting rod and a first fixing rod, and the adjusting rod is composed of a hydraulic rod and a second fixing rod; the hydraulic rod is connected together with the second fixing rod through a fixing base, and the top of the first fixing rod is connected together with the top of the second fixing rod through a first connecting frame; the bottom of the first fixing rod is connected with the bottom of the second fixing rod through a second connecting frame, and the locating device comprises an upper support base and a movable base. According to the obstetric table, the split structure is adopted, so that the whole obstetric table is good in disassembly and assembly ability and convenient to adjust at the same time; movement and quick fixation can be achieved at the same time, and the obstetric table with the split structure has the advantages of being simple practical in structure, convenient to fix quickly and move and worth promoting.

Owner:李达

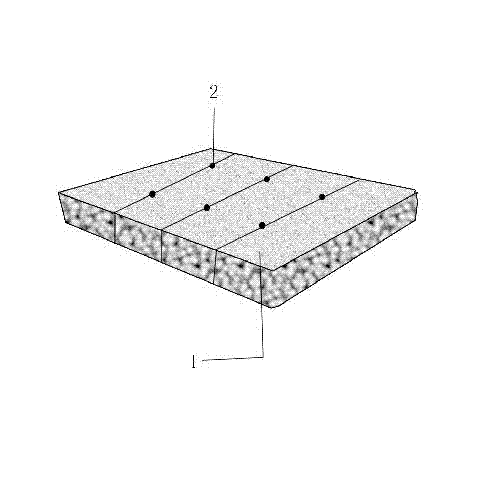

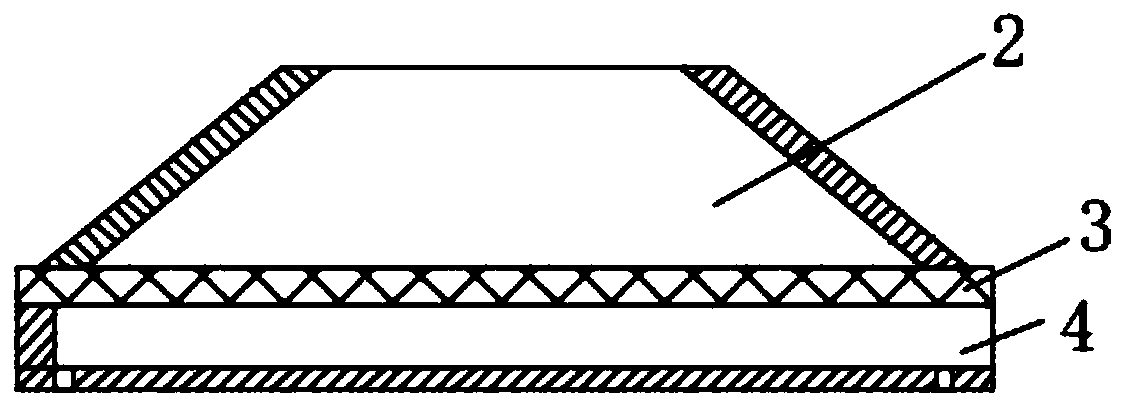

Extensible mattress

InactiveCN103082730ARealize detachableConvenient and detachableStuffed mattressesSpring mattressesMedicineEngineering

In order to effectively expand the function of a mattress, and change the size of the mattress according to the size of a bed, the original mattress is deliberately designed to be the combination of a plurality of mattress units. The extensible mattress can be disassembled or expanded based on the size of the bed, and is convenient during transporting.

Owner:重庆韵源科技有限公司

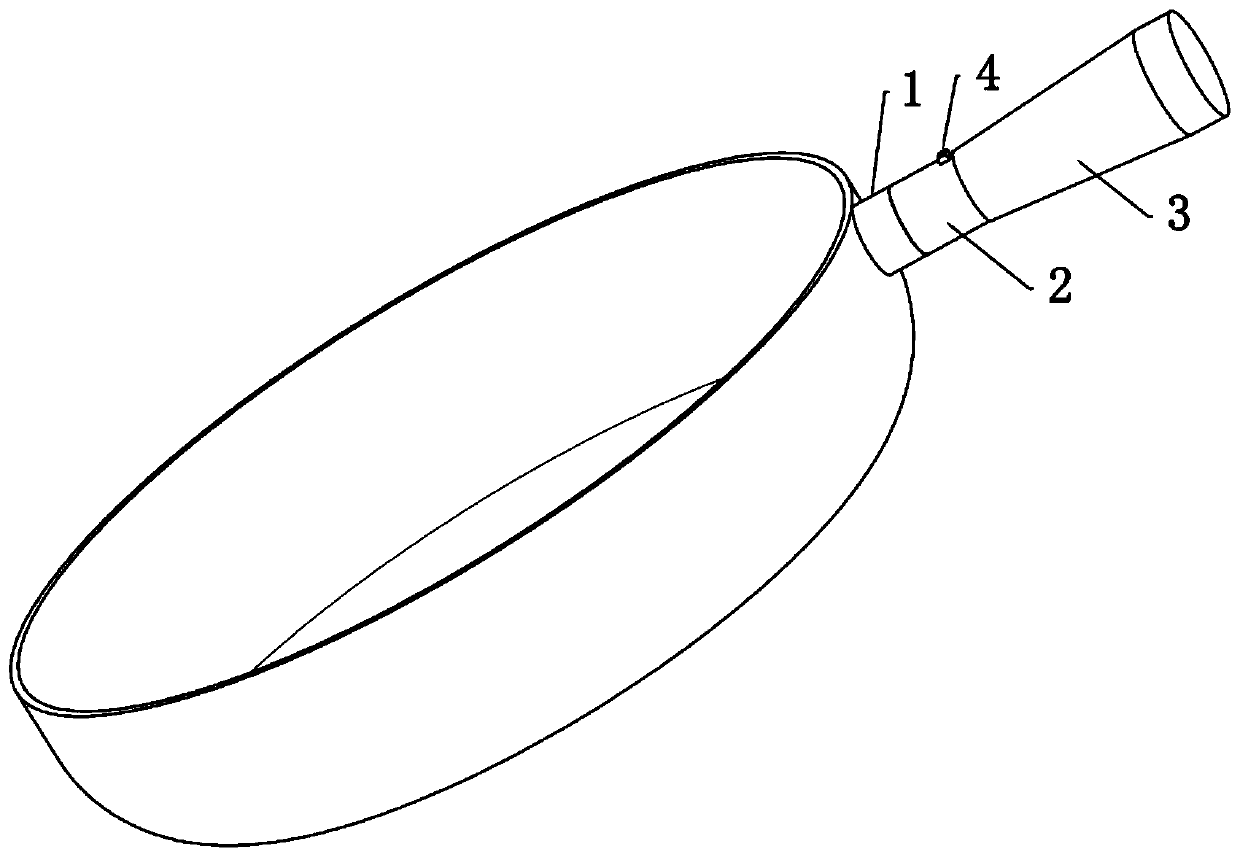

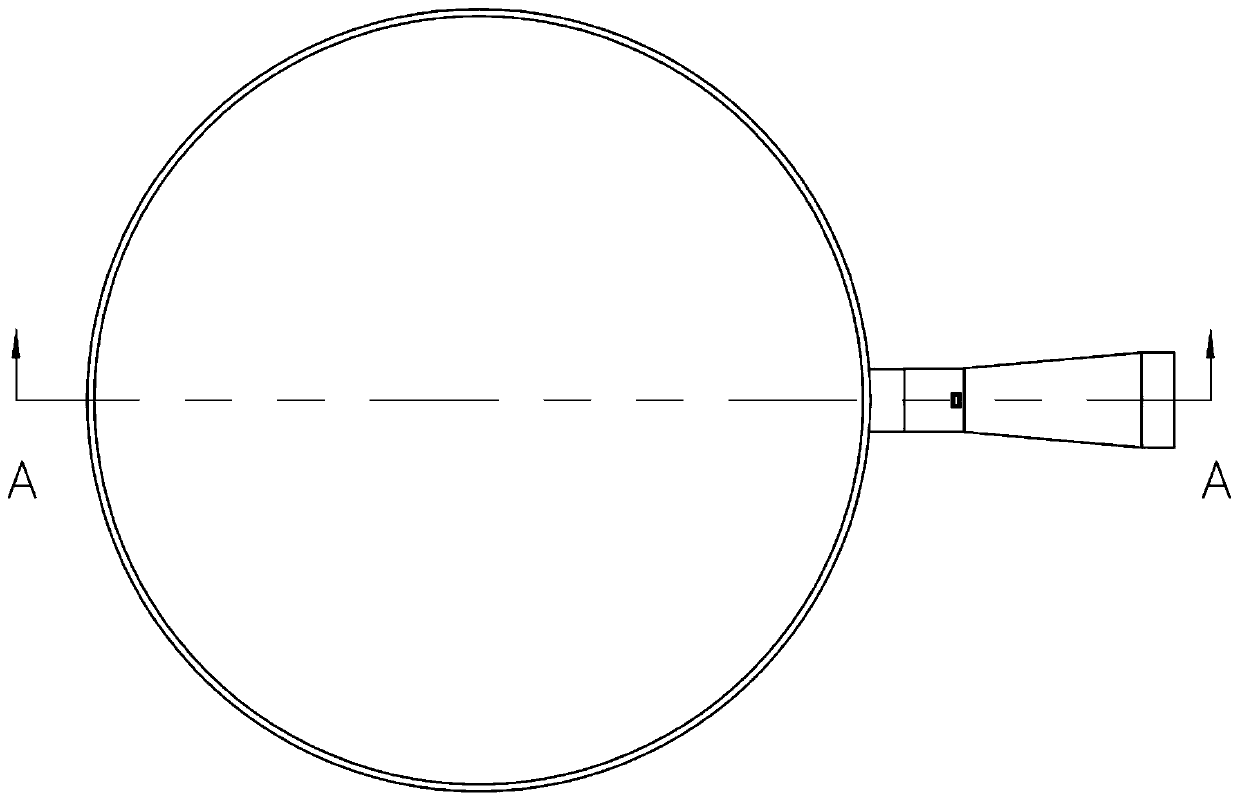

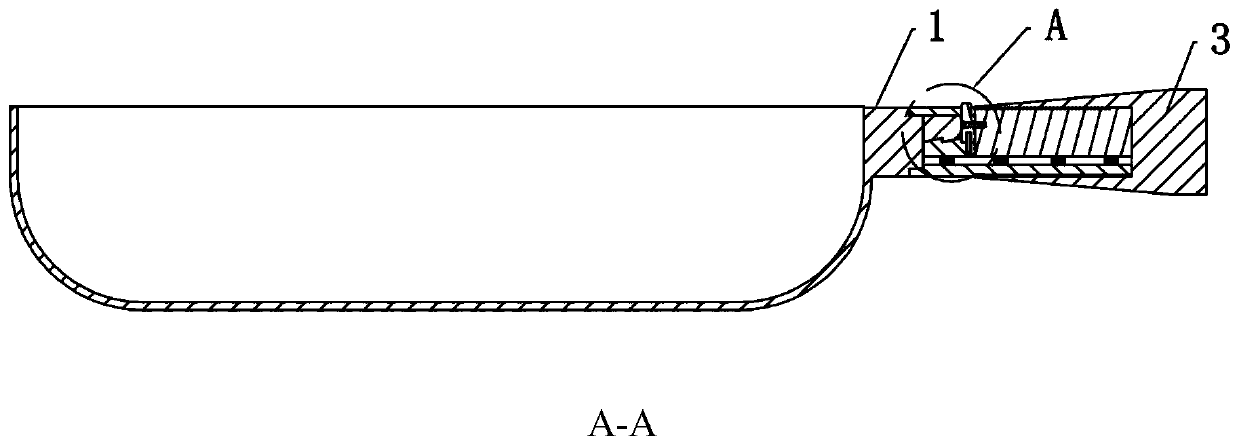

Pot handle easy to adjust and disassemble

ActiveCN110464229AHigh strengthSimple structure and operation modeKitchen equipmentMechanical engineeringEngineering

The invention relates to the field of cooking utensils, and discloses a pot handle easy to adjust and disassemble. The pot handle comprises a pot handle base and a pot handle body. The pot handle bodycomprises a fixed section and an adjusting section arranged outside the fixed section in a telescopic and sleeving mode. An occlusion limiting mechanism is arranged between the fixed section and thepan handle base. An adjustment and limiting mechanism is arranged between the fixed section and the adjustment section. The occlusion limiting mechanism comprises a first occlusion block arranged on the pan handle base in a protruding mode and a second occlusion block arranged in the fixed section in a lifting mode and occluded with the first occlusion block. The adjusting and limiting mechanism comprises a tooth block longitudinally arranged in the fixed section in a lifting mode and a rack arranged on the inner wall of the adjusting section and engaged with the tooth block. Teeth of the tooth block extend in the telescopic direction of the adjusting section. The second meshing block and the tooth block are fixedly arranged. Reset springs are arranged at the bottom of the second meshing block and the bottom of the tooth block. A driving block for driving the second meshing block and the tooth block to ascend and descend is arranged on the second meshing block or the tooth block. The pot handle easy to adjust and detach is low in production difficulty, low in manufacturing cost and convenient to operate.

Owner:浙江意可味厨具制造有限公司

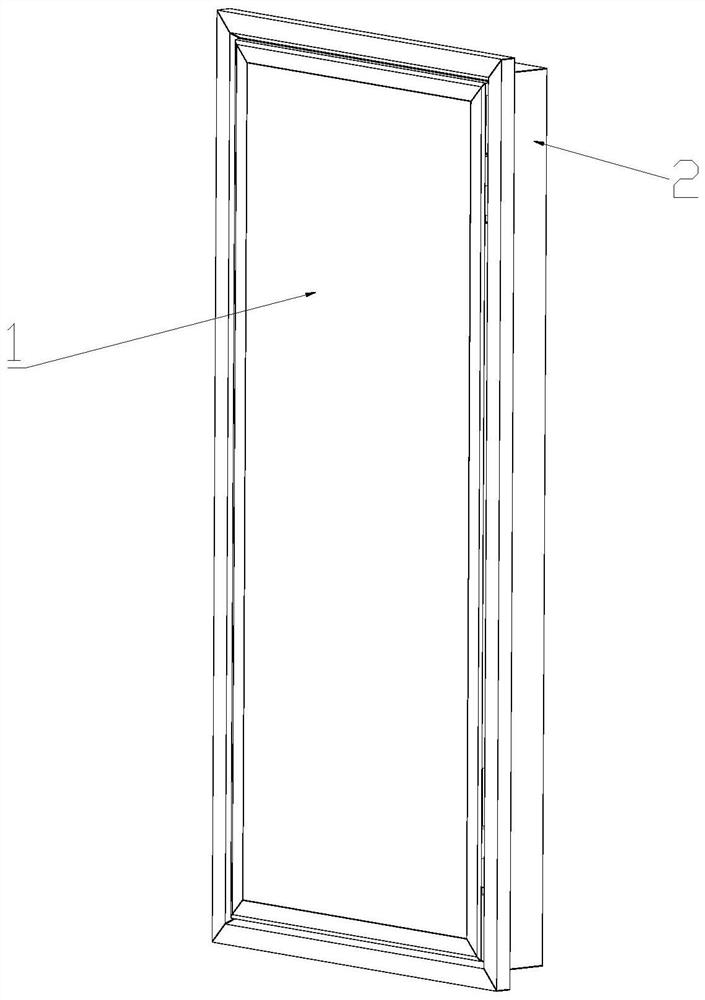

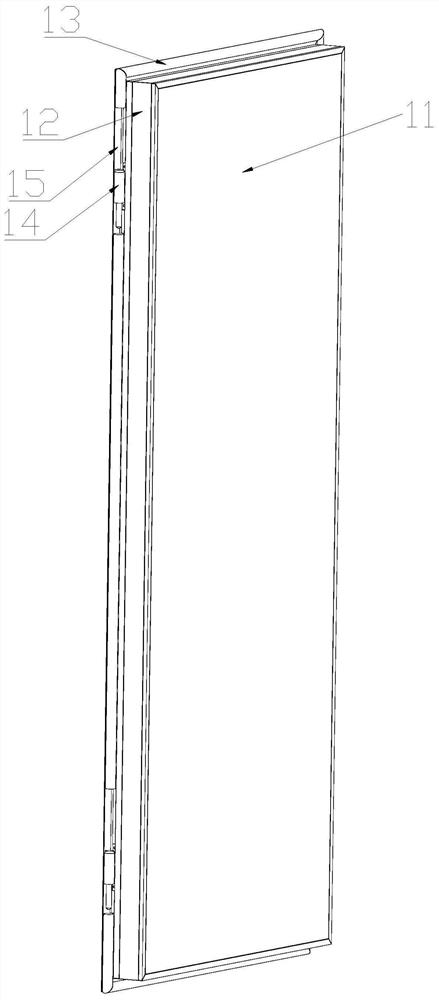

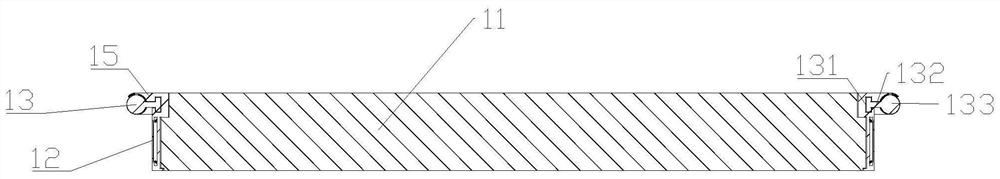

Door frame sleeve convenient to disassemble and assemble

PendingCN112412244ARealize detachable activity assemblyConvenient and detachableWindow/door framesPin hingesMechanical engineeringIndustrial engineering

The invention relates to the field of door frames, and particularly relates to a door frame sleeve convenient to disassemble and assemble. With the movable connecting of a bolt rotating shaft assemblyand with a bolt hinge assembly, the door body and a door frame are detachably and movably assembled, namely the door body and the door frame are very convenient to disassemble and assemble, and can be detachably carried and transported; the bolt rotating shaft assembly and the bolt hinge assembly can be used for a long time through cooperation, and lubricating liquid and the like can be conveniently added. The door frame, a door body clamping edge, the bolt rotating shaft assembly and the bolt hinge assembly can be produced in a modular mode, so that the cost is reduced, the precision is improved, and meanwhile, the application range is wide; standardized and large-scale production can be achieved, and the product stability and the integration are high. The invisibility and the attractiveness of the connection between the door body and the door frame are good, meanwhile, the quality manufacturing and upgrading of industrial products are promoted, the production cost is reduced, and the benefits are improved. The produced product is high in precision and cannot move, and the after-sales problem and the maintenance cost are reduced.

Owner:朱静敏

Lift with detection device for detecting displacement of door ball of lift hall door

ActiveCN108569605AAchieve precisionConvenient and detachableElevatorsBuilding liftsImaging processingEngineering

The invention relates to the technical field of a lift, in particular to a lift with a detection device for detecting displacement of a door ball of a lift hall door. The lift comprises a lift main body; the lift main body comprises a lift hall car door linkage device; the lift hall car door linkage device comprises a lift door opening machine arranged on a lift car as well as a landing door device arranged on the lift hall door; the lift door opening machine comprises a door knife; the landing door device comprises a door ball linked with the door knife and further comprises a photographing detection system; the photographing detection system comprises a photographing device and an image processing system; the photographing device is connected with the image processing system; the photographing detection system further comprises a shell; the photographing device and the image processing system are arranged in the shell; a light-transmitting opening is formed in the shell; the photographing direction of the photographing device faces towards the light-transmitting opening; the photographing direction of the photographing device faces towards the door ball through the light-transmitting opening; the shell is fixed on the door knife. The traditional photographing detection system for detecting displacement is arranged on the door knife, so that displacement monitoring of the doorball is realized.

Owner:上海富士电梯有限公司

Pencil sharpener based on pencil point adjustment

InactiveCN114523791ASimple structural designReasonable structural designSharpenersEngineeringNeedle sharpener

The invention discloses a pencil sharpener based on pencil point adjustment. The pencil sharpener comprises an automatic pencil feeding structure, a self-starting structure, a knife rest, a gear adjusting structure, a pencil point protection structure and a detachable pencil sharpening frame. The detachable pencil sharpening frame comprises an upper portion, a middle portion and a lower portion, the automatic pencil feeding structure is arranged on the upper portion, the knife rest is arranged in the middle portion, the gear adjusting structure is arranged on the lower portion, and the self-starting structure and the pencil point protecting structure penetrate through the upper portion, the middle portion and the lower portion. The pencil sharpener based on pencil point adjustment is simple in structure, convenient to operate, relatively low in cost and long in service life.

Owner:NINGBO TIANTIAN STATIONERY CO LTD

Detachable extrusion device for ceramic membrane production

InactiveCN108246118AMix well and thoroughlyAvoid it happening againSemi-permeable membranesMembranesHelical bladePulp and paper industry

The invention discloses a detachable extrusion device for ceramic membrane production. The device comprises a support frame; a motor is arranged at the top of the support frame; a stirring box is arranged at one side of the motor; a stirring shaft is arranged in the stirring box; the surface of the stirring shaft is provided with helical blades; one side of the stirring box is provided with an extrusion box; a cylinder is arranged at the top of the extrusion box; a connecting rod is arranged at the bottom of the cylinder; an extrusion plate is arranged at the bottom of the connecting rod; discharge holes are arranged at the bottom of the extrusion box; and a material receiving box is arranged at the bottom of the extrusion box. According to the invention, with the arrangement of the helical blades and the stirring shaft, ceramic membrane raw materials can be fully stirred before raw materials for ceramic membrane production are extruded, so that various raw materials are mixed more thoroughly, and the extrusion quality is ensured; through the arrangement of a vacuum pump, air in a box body is first pumped out during extrusion, so that air bubbles are prevented during extrusion; thewhole machine structure is simple, the use is convenient, and the extrusion quality is improved.

Owner:合肥万呈鑫陶瓷膜科技有限公司

Flue gas desulfurizing and dust removing device applied in field of environment protection

InactiveCN108379950AConvenient and detachableEnsure cleaning and maintenanceGas treatmentDispersed particle filtrationFlue gasFiltration

The invention discloses a flue gas desulfurizing and dust removing device applied in the field of environment protection. The flue gas desulfurizing and dust removing device includes a gas inlet pipeline, a desulfurization box, a connection block and support legs; the lower end of the gas inlet pipeline is connected with a dust removing cavity, an adsorption plate is transversely arranged inside the dust removing cavity, one side of a circulation cavity is fixedly connected with one end of a first connection pipeline, a reaction pool is formed in the desulfurization box, the other end of the first connection pipeline penetrates through the side wall of the desulfurization box and is connected with the reaction pool, a sewage pipeline is fixedly connected to the lower end of one side of thedesulfurization box, the other side of the desulfurization box is fixedly connected with one end of a second connection pipeline, the other end of the second connection pipeline is fixedly connectedwith a filtration box, a filtration plate is fixedly connected to the upper end of the connection block, a connection plate is arranged between the support legs, an exhaust fan is fixed to the upper end of the connection plate, and the other end of the exhaust fan is fixedly connected with a gas outlet pipeline. By the adoption of the flue gas desulfurizing and dust removing device applied in thefield of the environment protection, the problems are solved that current flue gas desulfurizing and dust removing devices are pool in airtightness and not convenient for later maintenance, besides, waste heat of flue gas cannot be fully utilized, and then energy waste is caused.

Owner:浙江格扬热工装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com