Building block type sensor

A sensor and building block technology, which is applied in the direction of instruments, electrical components, casings/cabinets/drawer components, etc., can solve the problems of inconvenient assembly of the casing, increase the difficulty of installing the sensor on the casing, and the complexity of the sensor structure, etc., to achieve assembly The effect of easy collocation operation, reassuring and more stable assembly, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "inner", "middle", "left", "right" and "one" quoted in this specification are only for the convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

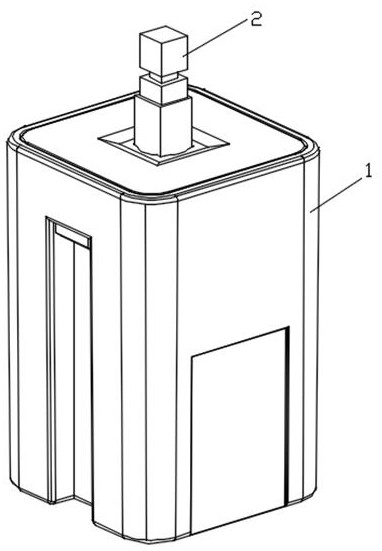

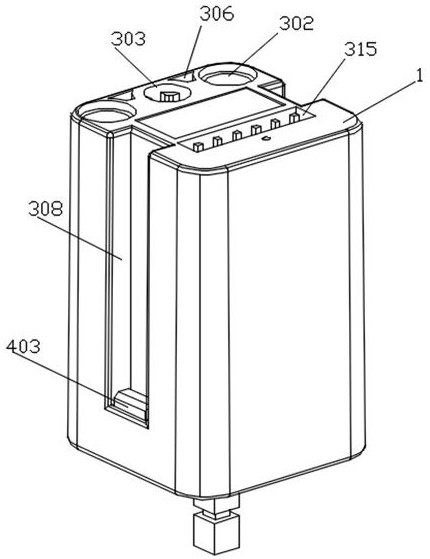

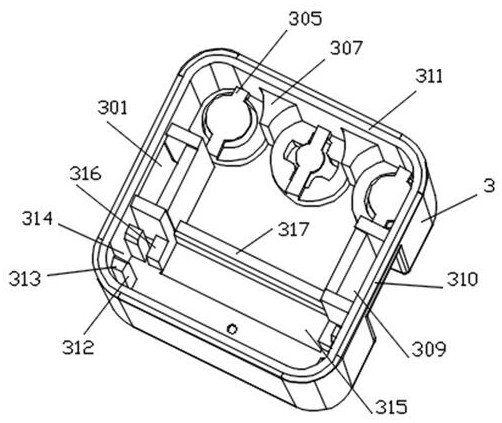

[0028] Such as Figure 1-2 As shown, a building block sensor includes a housing 1 and a sensor body 2 installed in the housing 1. The housing 1 includes a bottom shell 3 and a top cover 4. The bottom of the top cover 4 is provided with a buckle 401, and the bottom shell 3 is provided with a snap-in position 301 on the top, and the top cover 4 and the bottom case 3 are snapped into the buckle-in position 301 on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com