Walking polishing device for inner wall of small-diameter cylinder

A polishing device and technology in the cylinder, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of hidden safety hazards, time-consuming and laborious, and difficult polishing operations on the inner wall of the cylinder, and achieve reliable installation. Disassembly, high practicability and versatility, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

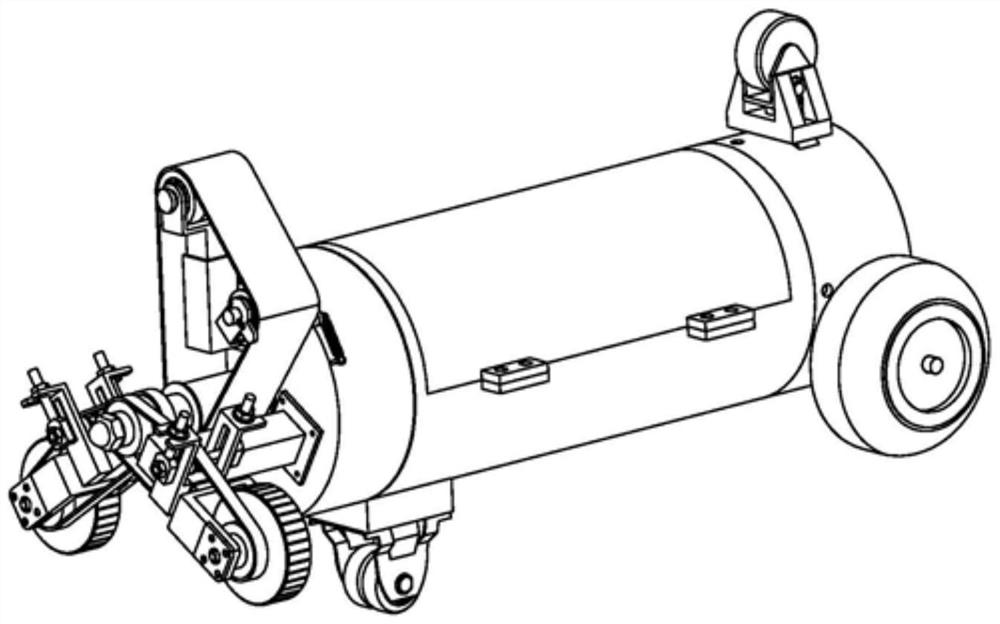

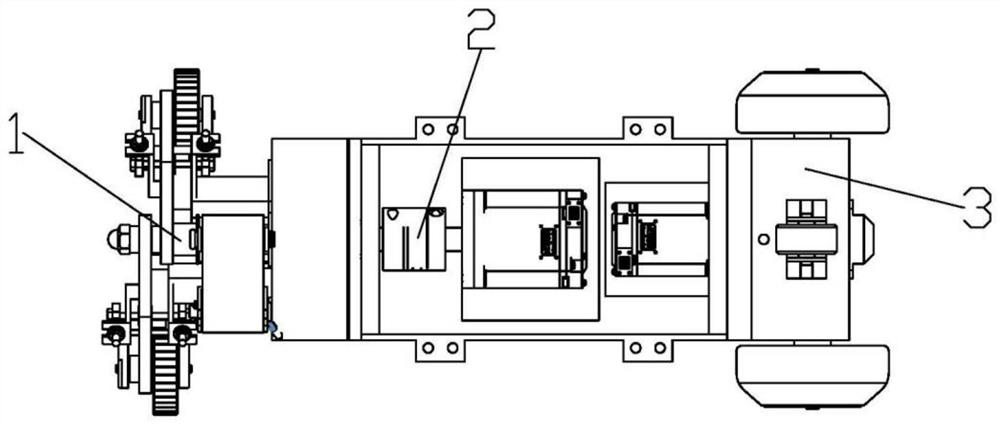

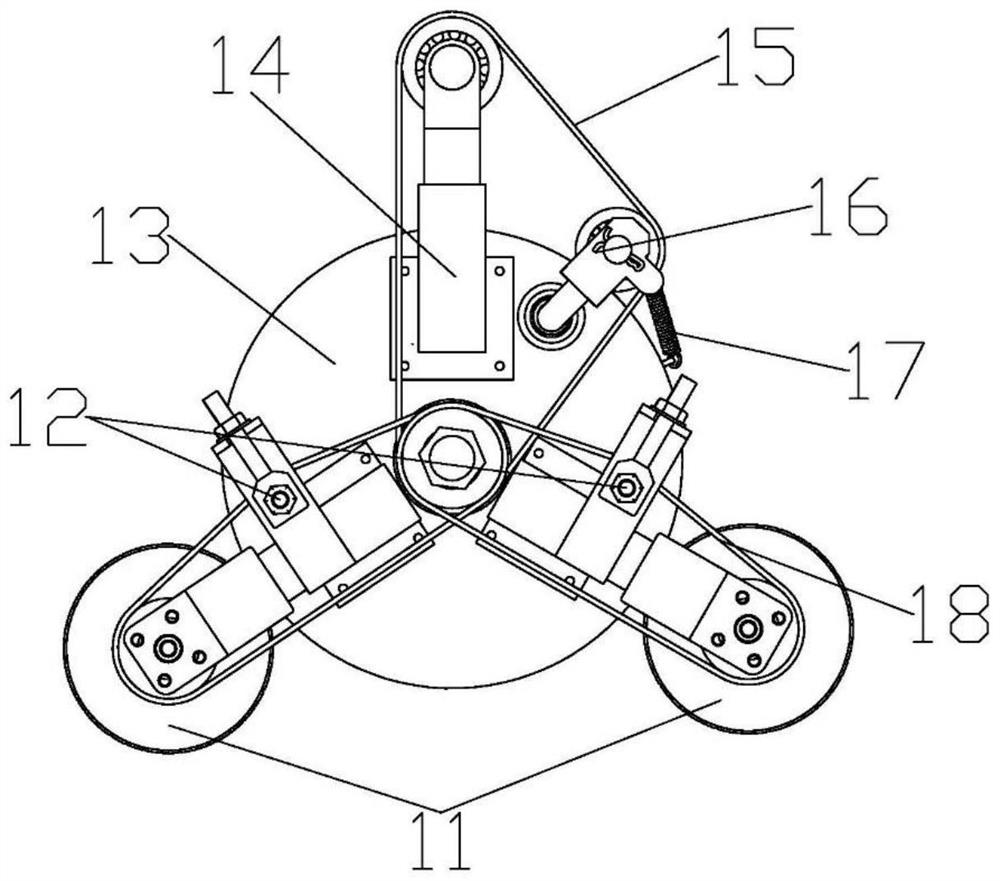

[0029] Such as Figure 1 to Figure 10 A walking polishing device for the inner wall of a small-diameter cylinder is shown, including a rotating polishing part 1, a rotating driving mechanism 2 and a walking driving structure 3; the rotating polishing part 1 is installed at the front end of the rotating driving mechanism 2, and the walking driving structure 3 is installed at the rear At least one polishing wheel 11 is installed on the rotary polishing component 1 through the polishing wheel fixing mechanism 12, and the polishing wheel fixing mechanism 12 can rotate relative to the rotary driving mechanism 2 along the center position of the rotary polishing component 1.

Embodiment 2

[0031] Based on Embodiment 1, the polishing wheel fixing mechanism 12 is fixed on the rotating front cover 13 , and the rotating front cover 13 is rotatably mounted on the front end of the rotating driving mechanism 2 .

Embodiment 3

[0033] Based on Embodiment 1, the polishing wheel 11 is driven to rotate by the synchronous belt 18, and the synchronous belt 18 is wound around the rotating mandrel 25, and the rotating mandrel 25 is driven by the servo motor 21 in the rotating drive mechanism 2 and installed through the rotating polishing unit 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com