Mortar glue

A mortar and quartz sand technology, applied in the field of mortar glue, can solve the problems of falling off cement mortar performance, large climate temperature difference, cracking, etc., and achieve the effect of strong weather resistance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

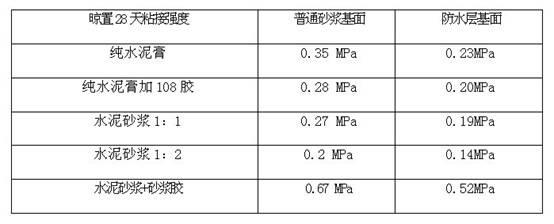

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of mortar glue, the parts by weight of each component in this mortar glue are respectively: vinyl acetate rubber powder or acrylic acid rubber powder 25 parts, hydroxypropyl methylcellulose 5 parts, mineral oil 0.5 calcium carbonate 69 parts, 0.5 part of polycarboxylate water reducer. Add the mortar glue of the present invention to cement mortar for tile laying: put 2 cups of the mortar glue measuring cup of the present invention on a flat top and pour 1 kilogram in total into the packaging barrel, add clear water to 6 liters, and stir with an electric tool After 5 minutes, let the mortar glue and clear water fully blend. According to the needs of the project, it can be directly mixed with cement and fine sand before use.

Embodiment 2

[0021] Embodiment 2: a kind of mortar glue, the parts by weight of each component in this mortar glue are respectively: 50 parts of acrylic rubber powder, 10 parts of guar gum, 1 part of organic silicon, 138 parts of quartz sand, polycarboxylate water reducing 1 dose. The mortar glue of the present invention is added in the cement mortar, is used for the paving of marble and natural stone: put the mortar glue measuring cup of the present invention into flat-top 4 cups and pour 2 kilograms into the packaging barrel in total, add clear water to 12 liters, Stir with an electric tool for 5 minutes to allow the mortar glue and water to fully blend. According to the needs of the project, it can be directly mixed with cement and fine sand before use.

Embodiment 3

[0022] Embodiment 3: a kind of mortar glue, the parts by weight of each component in this mortar glue are respectively: 20 parts of vinyl acetate rubber powder, 4 parts of hydroxypropyl methylcellulose and guar gum, 0.4 part of mineral oil and organosilicon, 55 parts of calcium carbonate and quartz sand, 0.4 parts of melamine-based water reducer. Add the mortar glue of the present invention to the cement paste for roughening the interface: add water to the mortar glue of the present invention, mix it with cement and stir it into a paste, and wipe it on the interface with a tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com