Negative ion performance measuring device and method for negative ion textile

A measuring device and technology of negative ions, applied in the field of measurement, can solve the problems of not considering the influence of temperature and negative ion performance, unable to accurately reflect the negative ion performance of negative ion fibers, trouble and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides an anion performance measuring device for anion textiles, which can satisfy the anion performance measurement of anion fibers and fabrics.

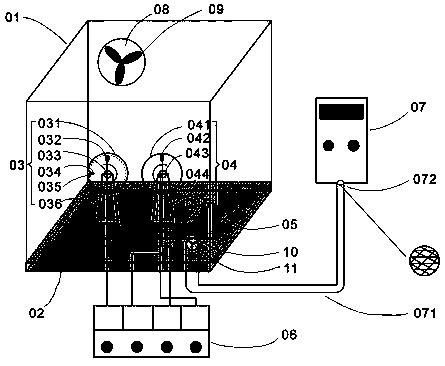

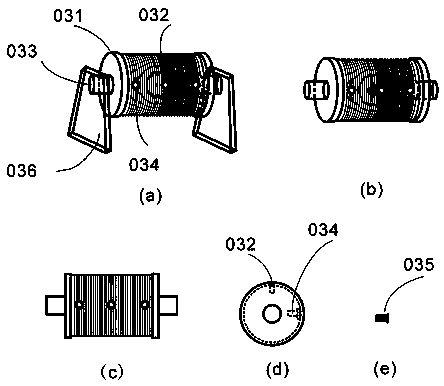

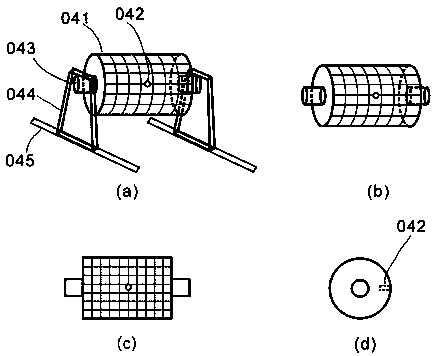

[0048] figure 1 It is a structural schematic diagram of an anion performance measuring device for anion textiles provided by the present invention. refer to figure 1 , the measuring device provided in this embodiment includes: a glass box (01), a box base (02), a winding pressure roller (03) installed on the box base, a transmission pressure roller (04) and a heating resistor (05 ), the temperature sensor (032) and the pressure sensor (042) installed in the winding drum (031) and the driving drum (041) respectively. In addition, the measuring device also includes an external test controller (06), an anion tester (07), an intake fan (09) and an exhaust fan (11) installed on the glass box, and a The guide rail (045) and the hollow tube (071) connecting the negative ion tester and the glass box. The windin...

Embodiment 2

[0053] This embodiment provides a method for testing the anion performance of anion textiles. This test method is based on an anion performance measuring device for anion textiles described in Example 1.

[0054] This test method includes the following steps:

[0055] A1. Determination of negative ion content in the air;

[0056] Let the winding pressure roller be unloaded, simultaneously turn on the intake fan (9) and exhaust fan on the glass box (01), turn on the power of the negative ion tester, and test the negative ion content in the air at room temperature.

[0057] Execute step A2 after step A1,

[0058] Step A2 is the fixing operation of the sample; the method is;

[0059] When the sample is anion fiber, remove the glass box (01), tie one end of the anion fiber to the inner cylinder of the winding drum, turn on the power of the winding roller, and let the winding drum rotate slowly. Control the direction of the fiber, so that the fiber is evenly wound one layer fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com