Negative ion measuring device and method for drum-type textile material

A textile material, measuring device technology, applied in the field of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

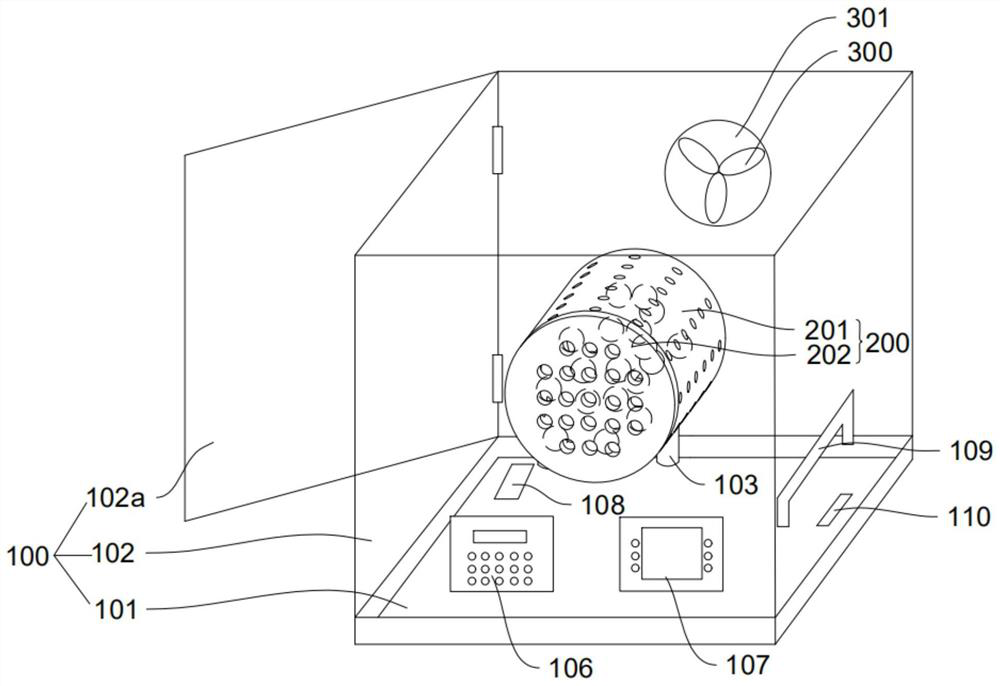

[0031] refer to figure 1 with figure 2 , is the first embodiment of the present invention, this embodiment provides a kind of negative ion measuring device and measuring method of drum type textile material, the negative ion measuring device and measuring method of drum type textile material comprise box assembly 100 and drum assembly 200, The box assembly 100 includes a base 101 arranged at the bottom, and a housing 102 vertically placed on the base 101, and a glass door 102a is hinged on the housing 102;

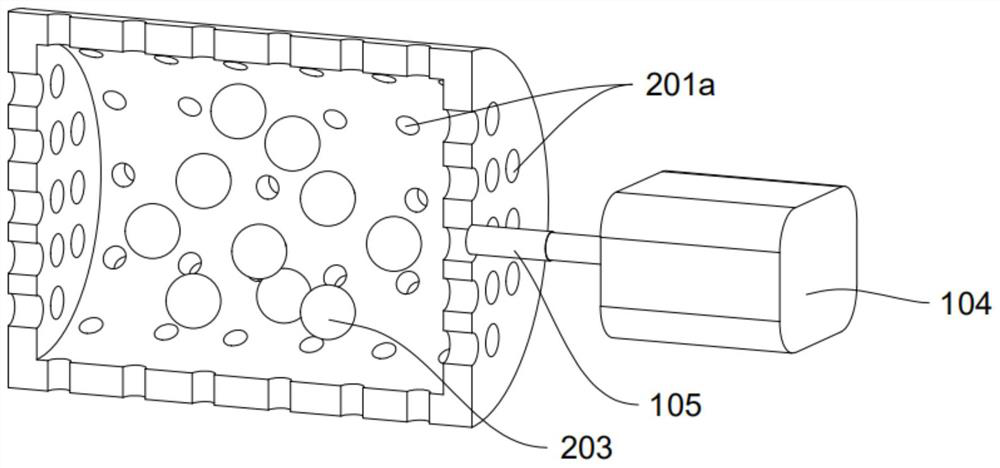

[0032] The roller assembly 200 is disposed inside the box assembly 100 and includes a cylinder 201 with a plurality of holes 201a evenly distributed in a circular shape, and a plurality of balls 203 placed in the cylinder 201 .

[0033] Based on the above, the box assembly 100 is in the shape of a cuboid, the base 101 is placed at the bottom, the casing 102 and the glass door 102a are placed around the base 101, and the top is also the casing 102, and the glass door 102a...

Embodiment 2

[0035] refer to Figure 1~2 , is the second embodiment of the present invention, which is different from the first embodiment in that: the drum assembly 200 also includes a cylinder cover 202 arranged on the cylinder body 201, the cylinder cover 202 and the cylinder body 201 are hingedly arranged, and the cylinder cover Several holes 201a are distributed at equal intervals on the surface of 202 .

[0036] Specifically, the method of testing the negative ions of the sample is divided into using the rotation of the drum assembly 200 to generate pressure to make the sample generate negative ions and raising the temperature to make the sample generate negative ions.

[0037] Based on the above, the cylinder assembly 200 includes a cylinder body 201 and a cylinder cover 202, the cylinder cover 202 is hingedly arranged with the cylinder body 201, and the diameter of the cylinder cover 202 is adapted to the diameter of the cylinder body 201 to prevent the sample inside the cylinder b...

Embodiment 3

[0048] refer to figure 1 and figure 2 , for the third embodiment of the present invention, this embodiment provides a kind of negative ion measurement method of drum type textile material, comprises the following steps:

[0049] Determine the negative ion content M in the air 0 ;

[0050] Put different samples into the cylinder 201 and put the balls 203 into the sample preparation operation;

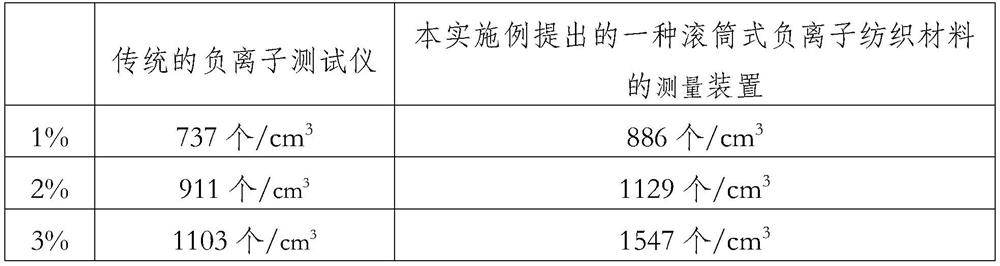

[0051] According to different ways to test the negative ion content of the sample, according to the number of tests, take the average value of the test results M 1 , and then use the average M 1 Subtract the negative ion content M in the air obtained by the test 0 , to obtain the number of negative ions produced by the sample under different test conditions.

[0052] Specifically, when the sample is anion fiber filament or yarn, take 1000 meters of anion fiber filament or yarn sample to be tested, and cut it into 10cm fiber bundles; when the sample is anion staple fiber, take 5g t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com