Polygonal cylinder type yarn grinding hairness and hair bulb tension holding pull measuring device and method

A measuring device and badminton technology, which are applied in the direction of measuring device, mechanical device, textile material inspection, etc., can solve the problem that the number of long hairs is small, the size of the entanglement and cohesion force of the appearance and morphological characteristics of the hair feather and the hairball cannot be obtained, and the test data is repeated. Sexual problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

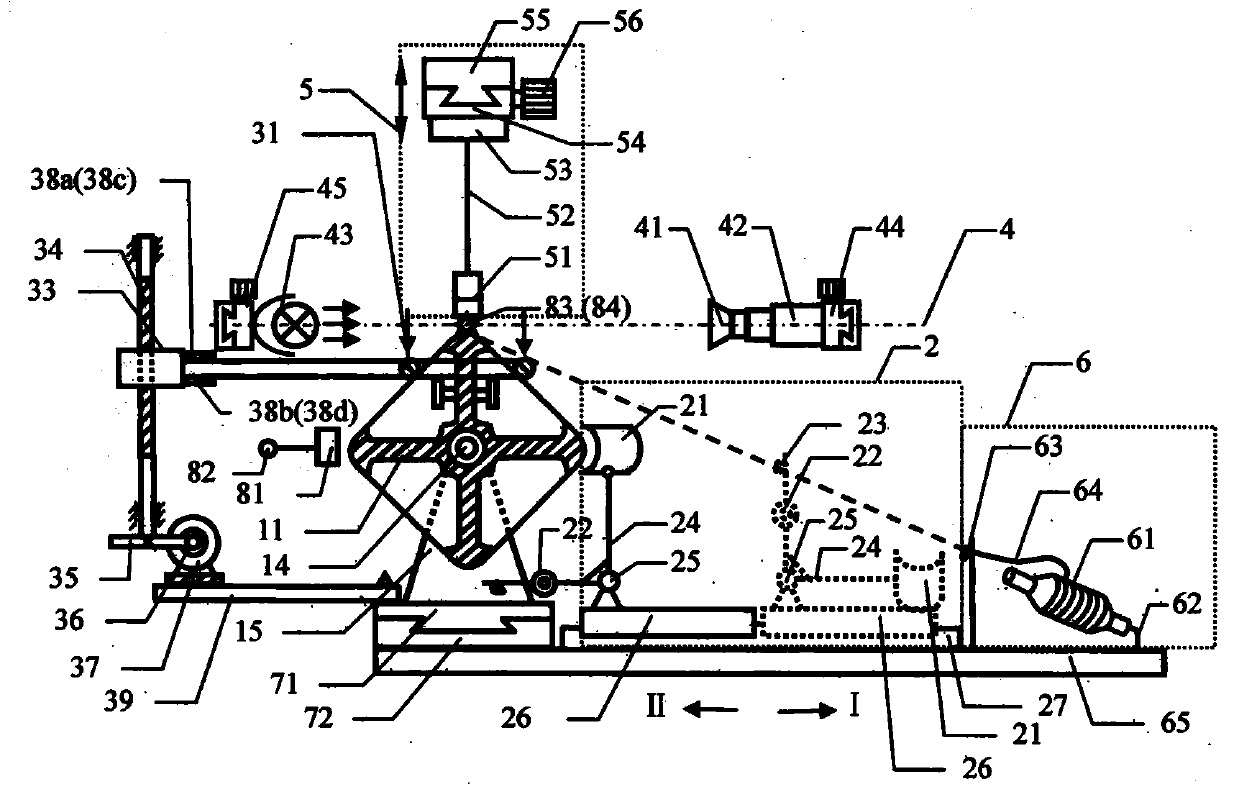

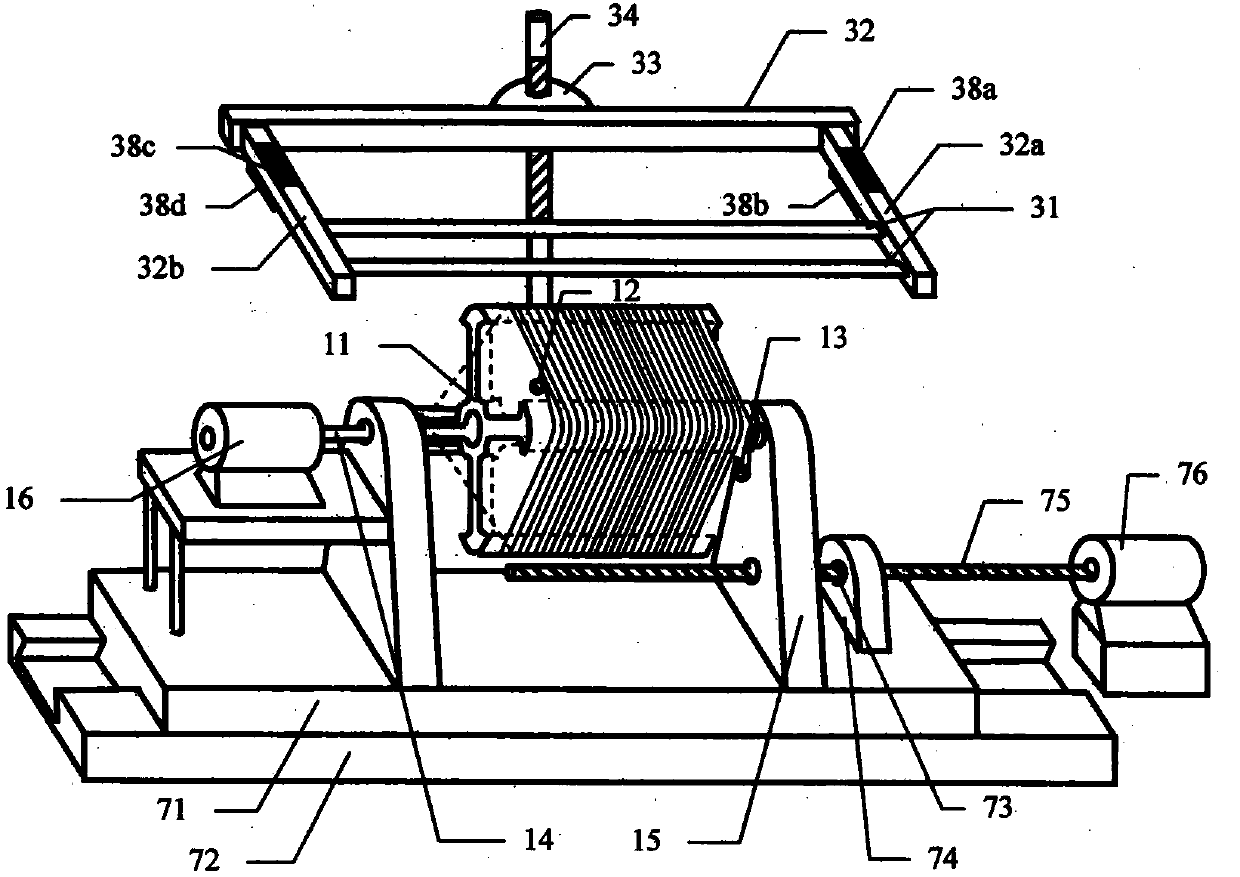

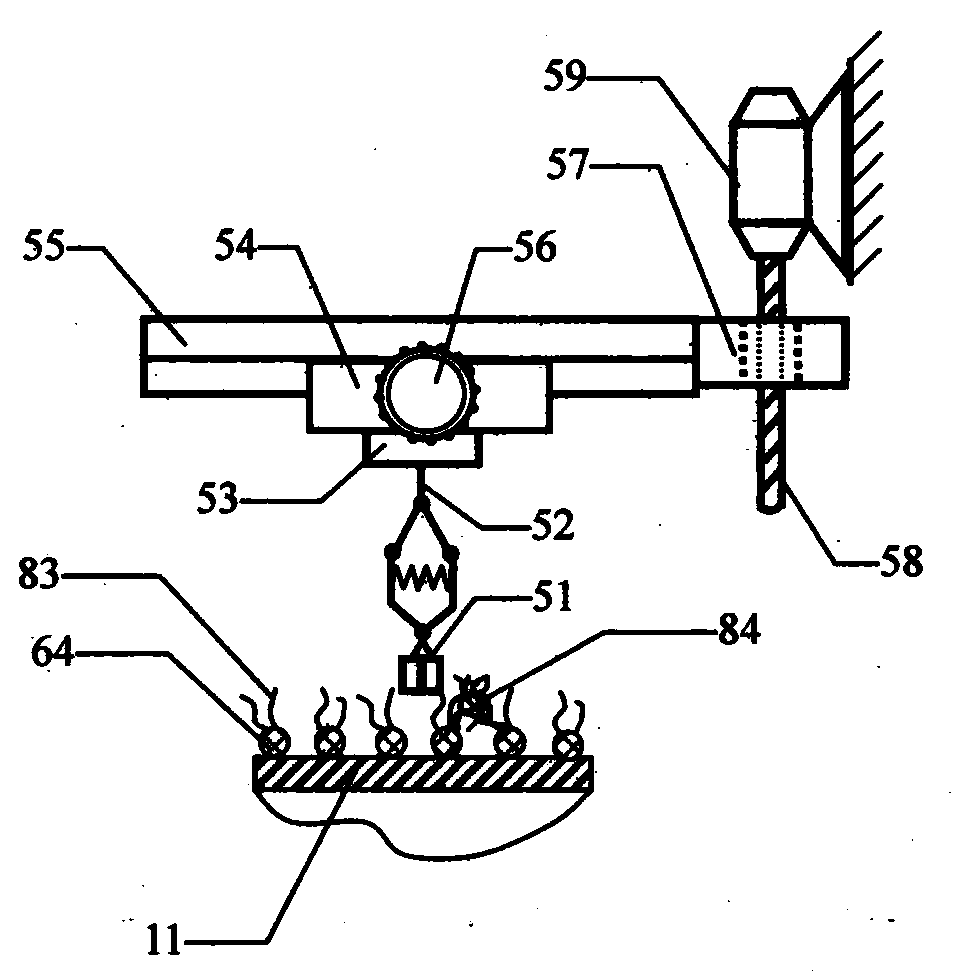

[0105] Using the triangular tube grinding yarn-grinding feather shuttlecock tension gripping and drawing measuring device and method of the present invention, the pilling and feather shuttlecock drawing of the full wool 2×8.2tex double-strand yarn with a yarn number of 16.4tex Force is measured, and its measurement condition parameter and actual measurement result are shown in the column of embodiment 1 in the table below and the extraction force measurement curve is shown in Figure 6 . From the measured results, it can be seen that the number of pills per unit area, the diameter of pills and their coefficient of variation obtained from the tangential observation of the worn full wool strands and the predicted yarn pilling level have a good consistency, indicating that the Effective and accurate devices and measurement methods. Telephoto microscope lens 41 and CCD camera 42 observe tangentially, the original yarn sample basically has no plush effect, while the polished yarn ...

Embodiment 2

[0107]Using the tension gripping and drawing measuring device and method of square tube grinding feather shuttlecock of the present invention, the pilling and pulling force of feather shuttlecock with yarn number of 13.1tex are measured, and the results are as follows: The measurement condition parameters and actual measurement results are shown in the column of Example 2 in the table below and the extraction force measurement curve is shown in Figure 6 . From the measured results, it can be seen that the number of pills per unit area, the diameter of pills and their coefficient of variation obtained from the tangential observation of the worn wool and acrylic blended yarn are in good agreement with the predicted yarn pilling level, indicating that The device and the measuring method are effective and accurate. The telephoto microscope lens 41 and the CCD camera 42 observe tangentially, the original yarn sample basically has no plush effect, while the polished yarn sample ha...

Embodiment 3

[0109] Adopting the tension gripping and drawing measuring device and method of the pentagonal barrel grinding feather badminton of the present invention, when the tension double rod 31 does not pressurize the yarn layer, the fluffing of the polyester-cotton blended yarn whose yarn number is 18.3tex Spherical and feather shuttlecock pulling force is measured, and its measurement condition parameters and actual measurement results are shown in the column of embodiment 3 in the table below and the pulling force measurement curve is shown in Figure 6 . From the actual measurement results, it can be seen that the number of hair balls per unit area obtained from the tangential observation of the worn polyester-cotton blended yarn is very small due to cotton fiber pilling, the diameter of hair balls is too large due to polyester pilling, and the coefficient of variation is small. and because of the difference in sampling volume, the CVD observed in the tangential direction is relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com