Rapid tester for paper pulp kappa number and control method of rapid tester

A measuring instrument, Kappa value technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of cumbersome steps and time-consuming, and achieve the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

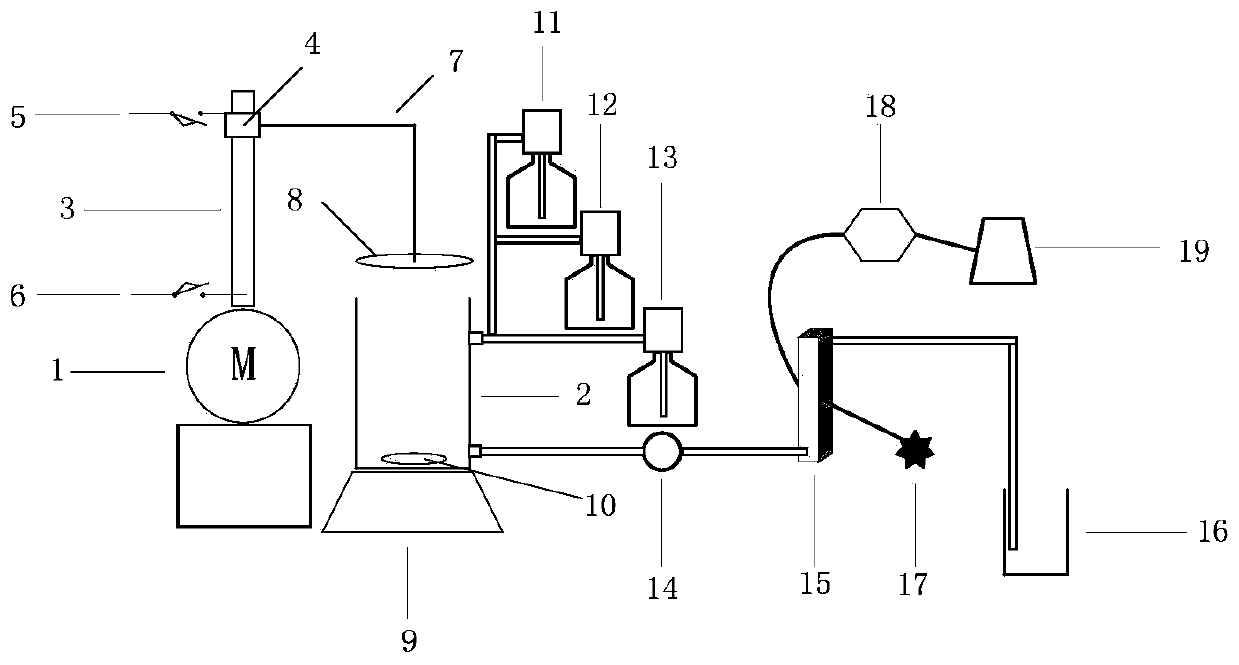

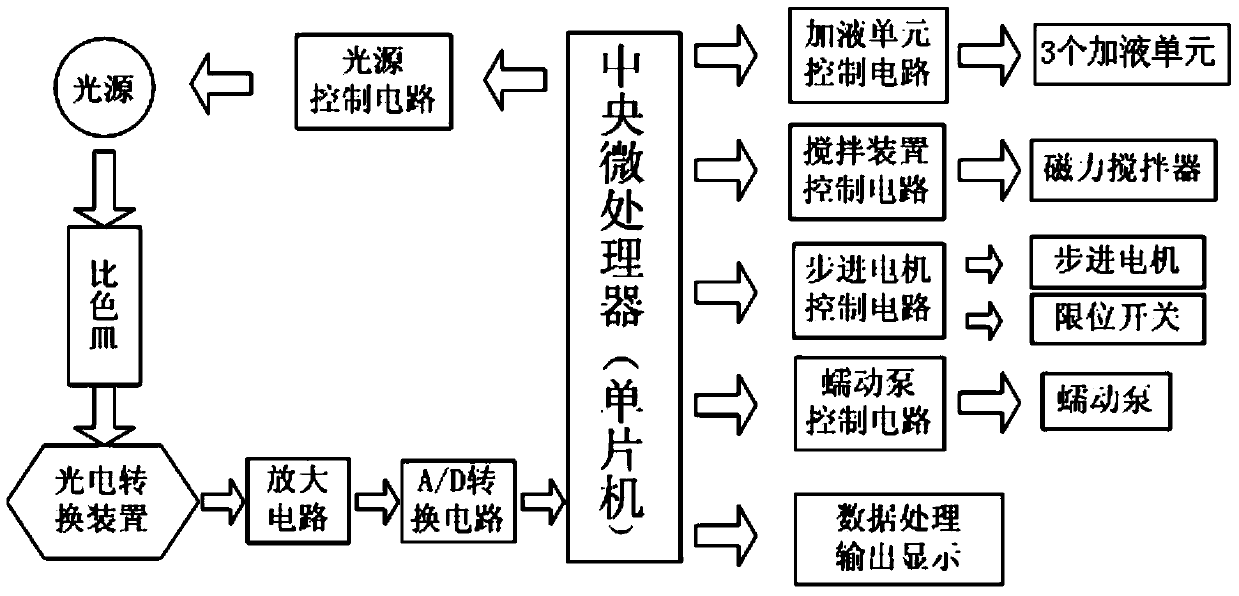

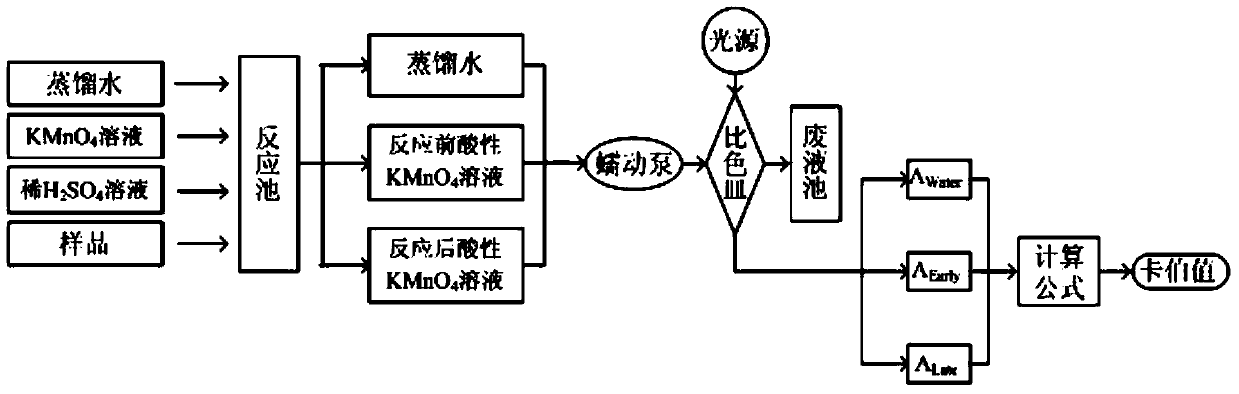

[0054] Such as figure 1 As shown, the rapid pulp kappa number tester of the present invention includes a reaction tank 2, three liquid addition units communicated with the reaction tank 2 and having the same structure, and a magnetic stirrer 9 carrying the reaction tank 2. These three liquid addition units are divided into It is the first liquid addition unit 11, the second liquid addition unit 12, and the third liquid addition unit 13; distilled water, KMnO 4 solution, H 2 SO 4 solution; and every liquid addition corresponds to the corresponding volume, these three liquid addition units add the above three liquids to the reaction pool 2 in a sequential manner, wherein distilled water is used for blank control and cleaning device, KMnO 4 solution and H 2 SO 4 The solution is used to prepare the reaction solution. The stirring rotor 10 of the magnetic stirrer 9 is placed in the reaction tank 2. The function of magnetic stirring is mainly to make the reaction in the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com