Multistage-separation progressive shield cutter head

A shield cutter head, multi-stage separation technology, which is used in mining equipment, earthwork drilling, tunnels, etc. problem, to achieve the effect of easy control of earth pressure balance, small cutting amount and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

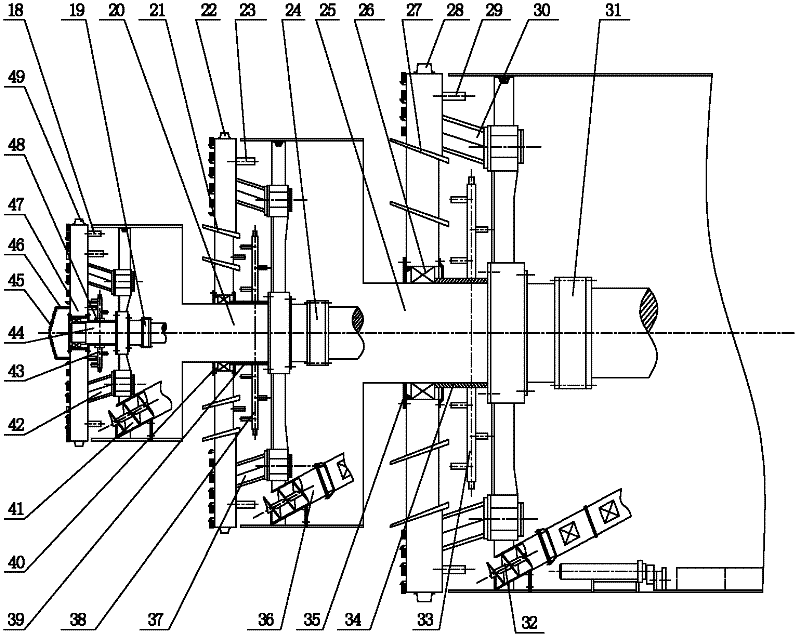

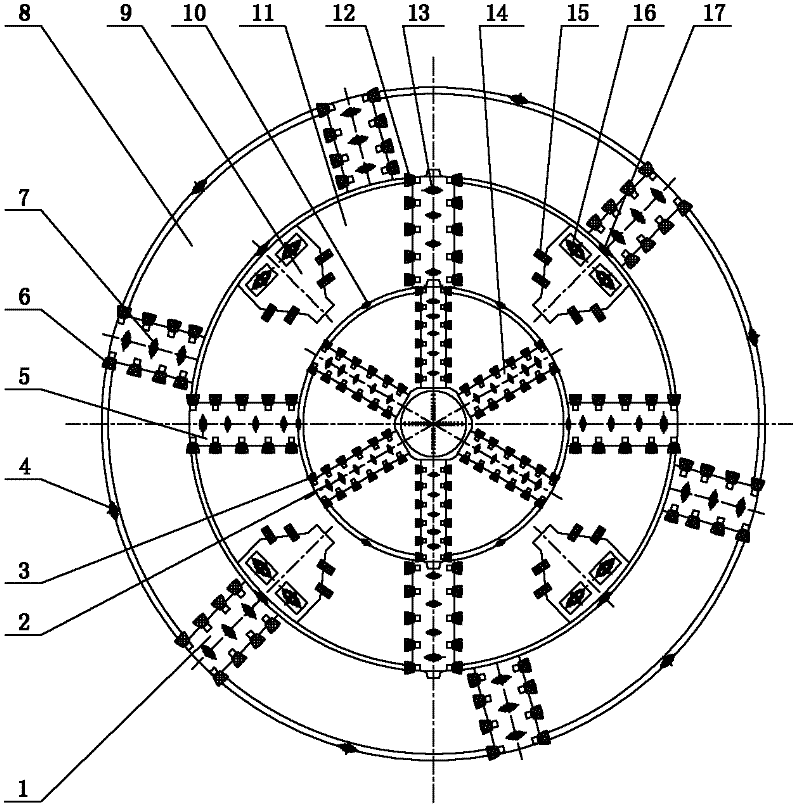

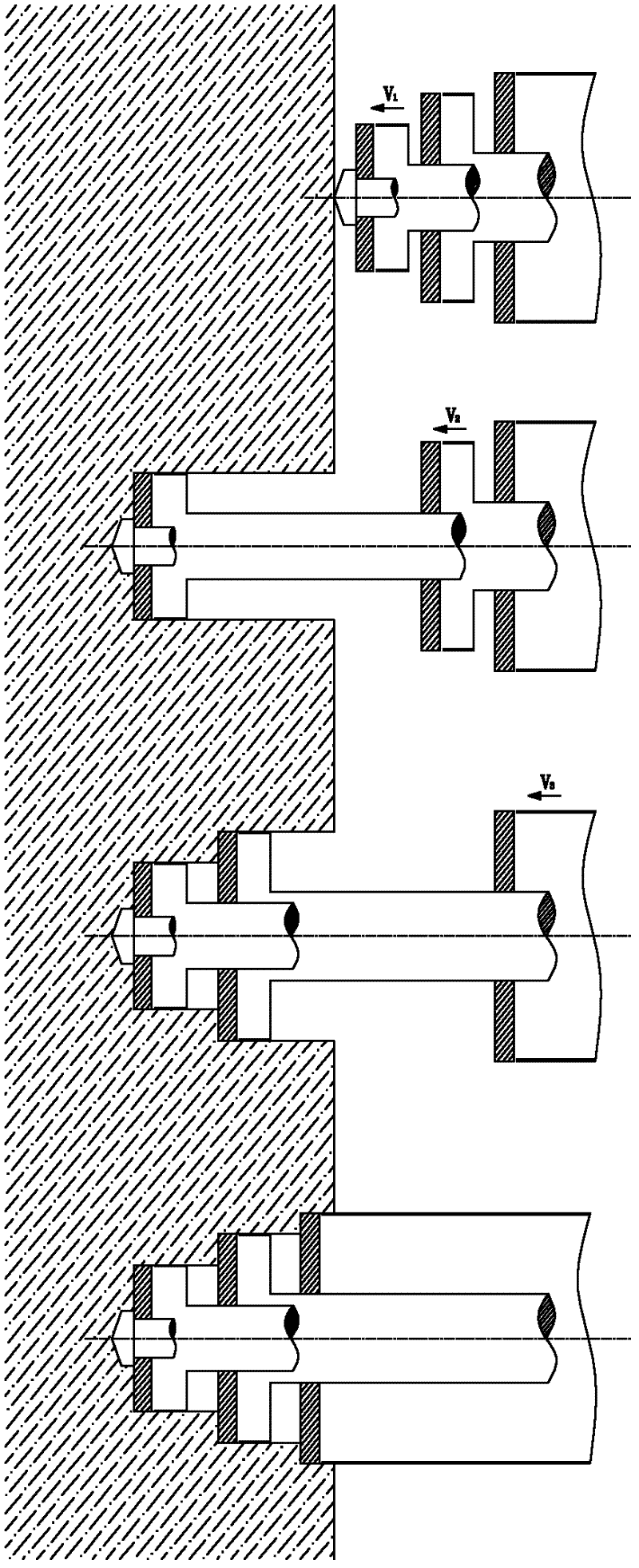

[0015] see figure 1 , figure 2 , the present invention comprises three stages of retractable stepped cutterheads, wherein the front end of the first stage cutterhead 47 is equipped with a drill bit 46 with a drill cutter 45, and the end face of the first stage cutterhead 47, that is, the face plate, adopts six spokes 14, and The six spokes 14 are respectively equipped with a first-level cutter hob 2 and a first-level scraper 3, and a first-level hob 10 and a first-level cutter 49 are installed on the outer edge of the first-level cutter 47, and the first-level cutter 47 passes through the bearing. And sealing device is installed on the primary rotary main shaft 44, and the primary power transmission device 42 that is fixedly connected with the primary cutter head is also installed on the primary rotary main shaft 44, the primary rotary main shaft 44 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com