Preparation method of nylon powder for selective laser sintering

A nylon powder and laser sintering technology is applied in the field of nylon powder preparation, which can solve the problems of reducing the oxidation resistance of nylon powder, reducing the recovery rate of organic solvents, cumbersome production operations, etc., and achieves easy implementation, regular powder morphology, and repeatability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

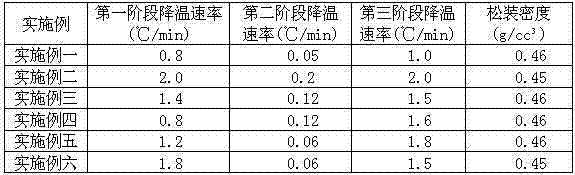

Embodiment 1

[0015] a. In 100Kg of methanol, add 10Kg of nylon 1212 pellets, under the pressure of 2.0MPa, stir at 170°C for 1.0h, and then lower the temperature. The cooling method adopts three stages of cooling, and the rate of the first stage is 0.8°C / min Cool down to 110°C; in the second stage, slowly cool down to 100°C at 0.05°C / min; in the third stage, quickly cool down to room temperature at 1.0°C / min. Centrifugal filtration, drying to obtain nylon 1212 powder, the powder shape is regular;

[0016] b. Mix the nylon 1212 powder obtained in step 1 with a flow aid and an antioxidant at a ratio of 1:0.003:0.003, and sieve after mixing evenly to obtain a selective laser sintering 1212 powder.

Embodiment 2

[0018] a. In 100Kg of ethanol, add 10Kg of nylon 1212 pellets, under the pressure of 2.0MPa, stir at 170°C for 1.0h, and then cool down. The cooling method adopts three stages of cooling, and the rate of the first stage is 2.0°C / min Cool down to 110°C; in the second stage, slowly cool down to 100°C at 0.2°C / min; in the third stage, quickly cool down to room temperature at 2.0°C / min. Centrifugal filtration, drying to obtain nylon 1212 powder, the powder shape is regular;

[0019] b. Mix the nylon nylon 1212 powder obtained in step 1 with flow aid and antioxidant at a ratio of 1:0.003:0.003, mix evenly and sieve to obtain a nylon 1212 powder for selective laser sintering.

Embodiment 3

[0021] a. Add 10Kg of nylon 1212 pellets to 100Kg of dimethyl sulfoxide, stir at 170°C for 1.0h under a pressure of 2.0MPa, and then cool down. The cooling method adopts three stages of cooling, and the rate of the first stage is: Cool down to 110°C at 1.4°C / min; slowly cool down to 100°C at 0.12°C / min in the second stage; quickly cool down to room temperature at 1.5°C / min in the third stage. Centrifugal filtration, drying to obtain nylon 1212 powder, the powder appearance is relatively regular;

[0022] b. Mix the nylon nylon 1212 powder obtained in step 1 with flow aid and antioxidant at a ratio of 1:0.003:0.003, mix evenly and sieve to obtain a nylon 1212 powder for selective laser sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com