Plate shell-type nonsaturated evaporation condensing plant

An evaporative condensation, plate-and-shell technology, used in evaporators/condensers, lighting and heating equipment, steam/steam condensers, etc., can solve the problem of weakened water spiral flow, poor heat transfer effect, and affected heat transfer effect. and other problems, to achieve the effect of increasing the sedimentation velocity, increasing the effective heat transfer area, and enhancing the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

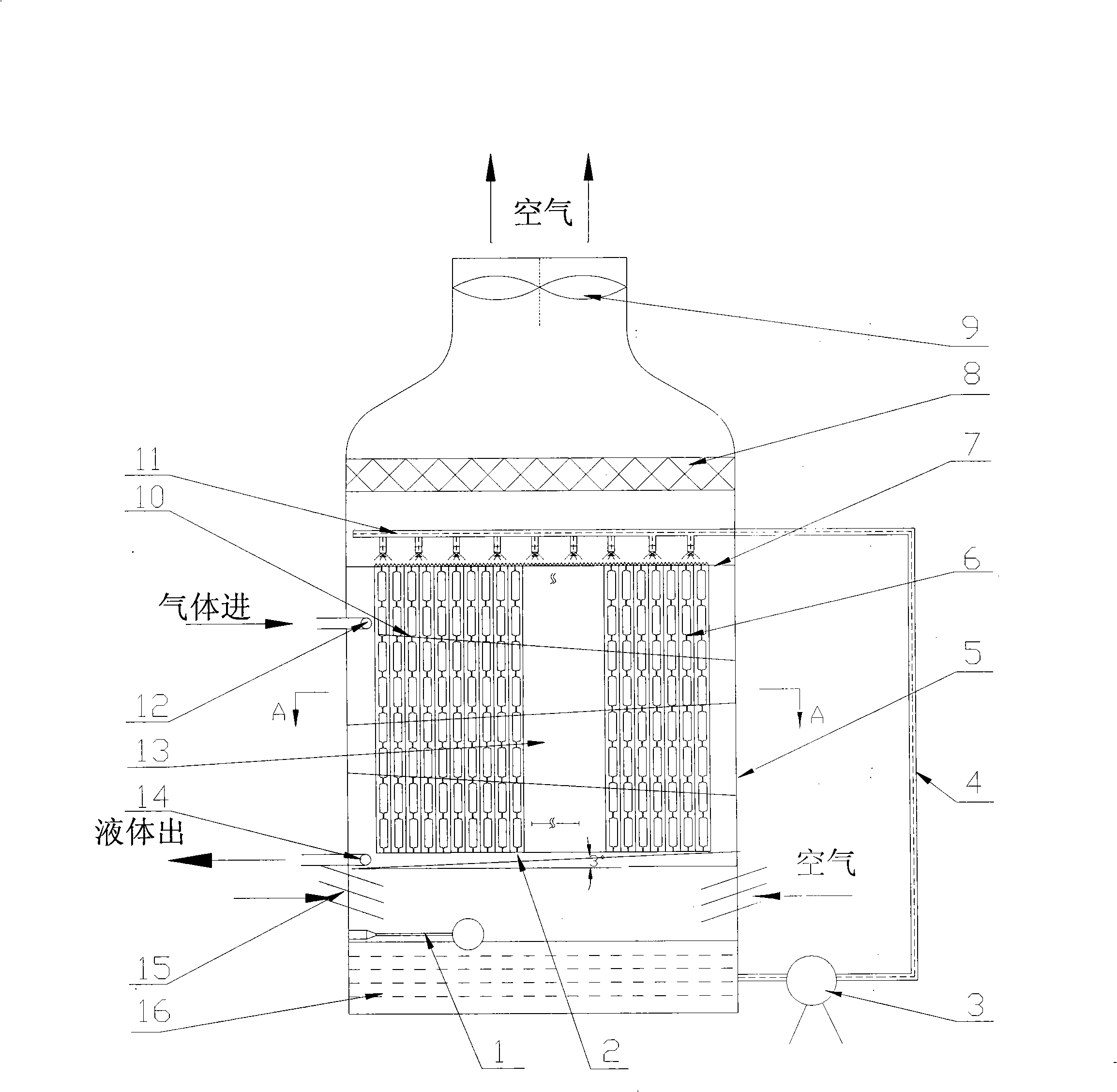

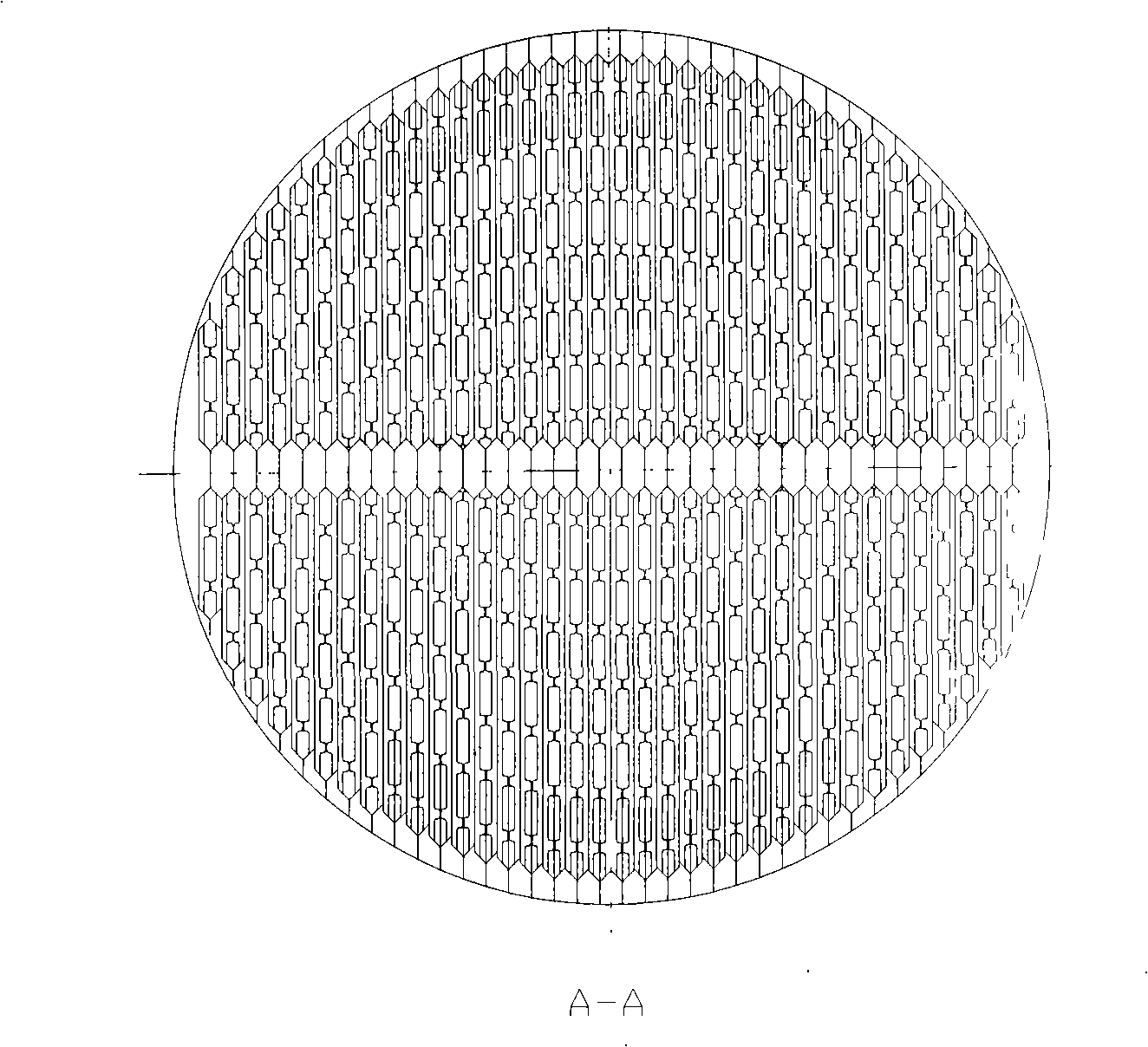

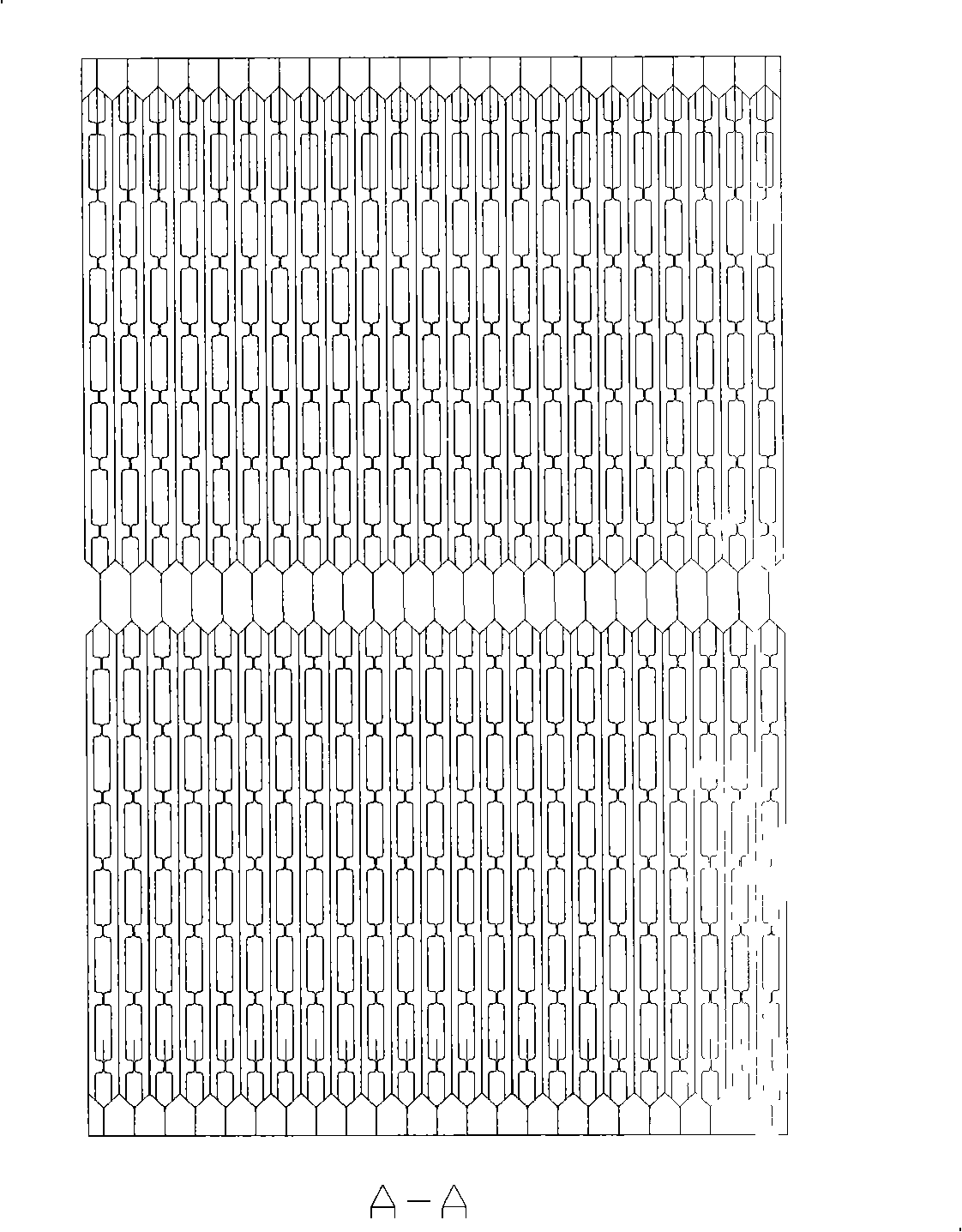

[0017] Such as figure 1 As shown, the plate-shell unsaturated evaporative-condensing equipment of the present invention includes an upper box, a lower box and a plate-shell heat exchanger 13 . The upper box contains an axial flow fan 9, a water baffle 8, and a top water collector 11 to realize the air circulation and water distribution of the cooling equipment; the lower box contains an air inlet grid 15, a float valve 1 and a bottom water collection tank 16. The air intake grid 15 is cylindrical and located on the upper part of the lower box, allowing air to enter the lower box from any direction; the top water collector 11 is connected to the bottom water collection tank 15 by the water pump 3 through the circulating water pipeline 4. The plate-shell heat exchanger 13 is fixedly connected with the upper box body and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com