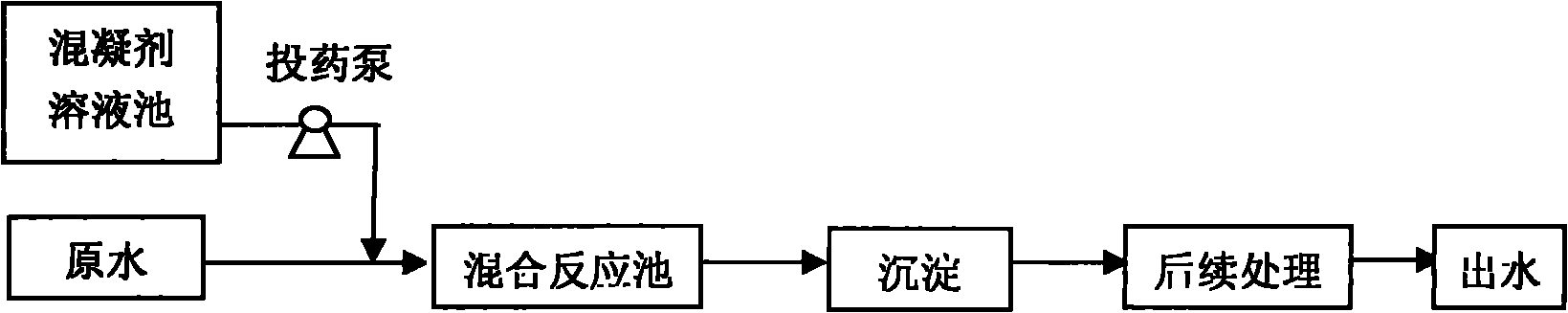

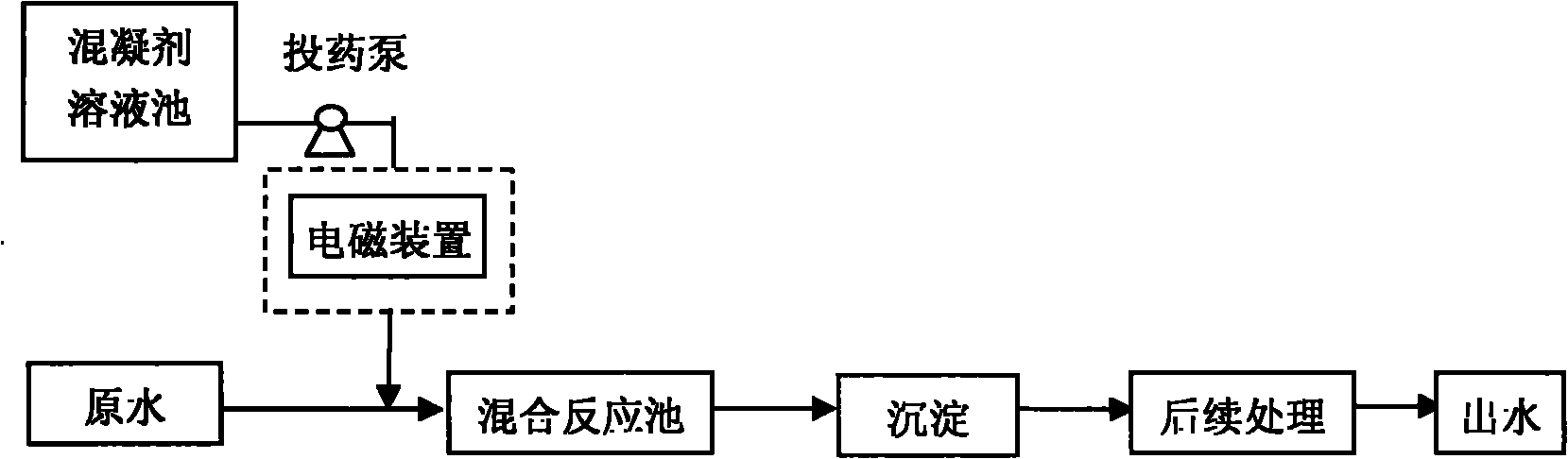

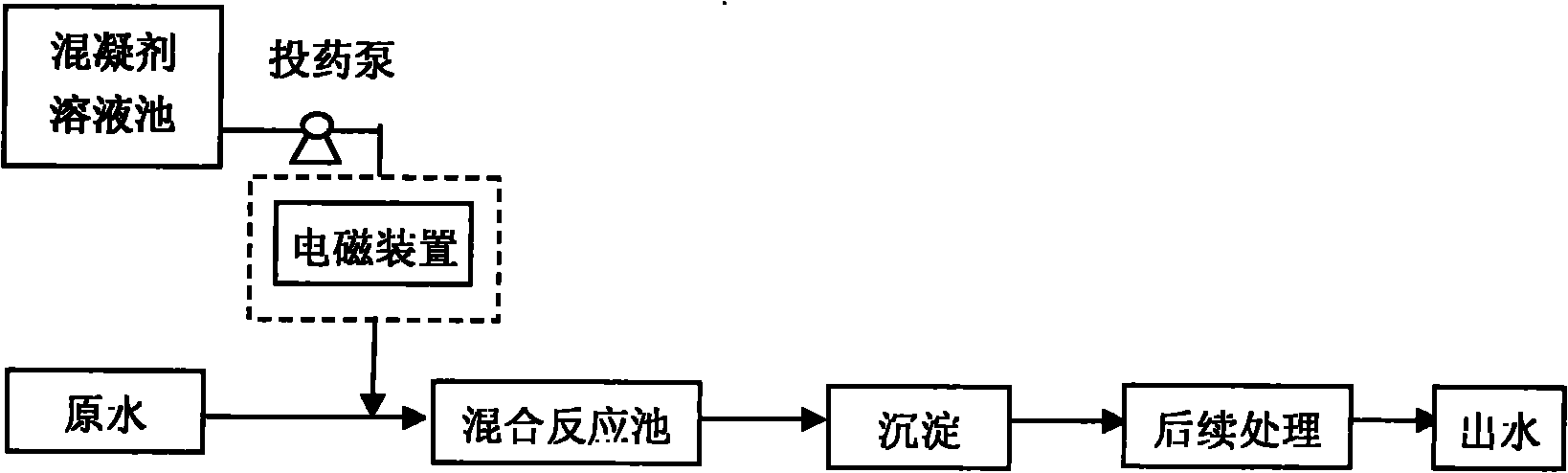

Electromagnetic coagulation treatment method

A treatment method and coagulation technology, which are applied in the fields of flocculation/sedimentation water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., which can solve the problems of high water content, large volume, and slow floc formation in sedimentation sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Treat raw water: Yellow River water, turbidity is 680NTU

[0011] Coagulant: 2% polyferric sulfate (PFS) solution

[0012] Coagulation conditions and equipment: laboratory standard coagulation mixing conditions, intelligent coagulation experimental mixer

[0013] ① Take the coagulant solution directly for coagulation experiment, the optimal dosage is 60mg / l, the turbidity of the precipitated water is 5.88NTU, and the moisture content of the sludge is 91.4%;

[0014] ② Install a magnetization device on the coagulant dosing tube to magnetize the coagulant solution in the electromagnetic device (magnetic field strength 44.6mT, magnetization time 5min), and then carry out coagulation experiments. The optimal dosage is 40mg / l, and the precipitation The water turbidity is 1.66NTU, and the moisture content of the sludge is 87%;

[0015] ③The magnetized coagulation effect is significantly better than the non-magnetized coagulation effect (the turbidity is reduced by 4.22NTU),...

Embodiment 2

[0018] Treat raw water: Yellow River water, turbidity is 700NTU

[0019] Coagulant: 7% rare earth coagulant solution (PRC)

[0020] Coagulation conditions and equipment: laboratory standard coagulation mixing conditions, intelligent coagulation experimental mixer

[0021] ① Take the coagulant solution directly for coagulation experiment, the optimal dosage is 28mg / l, the turbidity of the precipitated water is 4.32NTU, and the moisture content of the sludge is 78.6%;

[0022] ② Install a magnetization device on the coagulant dosing tube to magnetize the coagulant solution in the electromagnetic device. The optimum magnetic field strength is 60.1mT, and the magnetization time is 6min. l, the turbidity of sedimentation water is 3.51NTU, and the moisture content of sludge is 75%;

[0023] ③The effect of magnetized coagulation is significantly better than that of non-magnetized coagulation (the turbidity is reduced by 0.81NTU), the dosage can be reduced by 25%, the moisture conte...

Embodiment 3

[0026] Raw water treatment: secondary sedimentation tank of municipal sewage plant, turbidity is 6NTU, COD is 68mg / l

[0027] Coagulant: polyferric sulfate (PFS) solution, polyaluminum chloride (PAC) solution, rare earth coagulant solution (PRC)

[0028] Coagulation conditions and equipment: laboratory standard coagulation mixing conditions, intelligent coagulation experimental mixer

[0029] ① Take coagulant solution directly for coagulation experiment;

[0030] ② Take the coagulant solution and magnetize it in the electromagnetic device, and then carry out the coagulation experiment.

[0031] ③ Due to the low turbidity of raw water, there is no significant difference in dosage, turbidity of sedimentation water and COD removal rate

[0032] However, the effect of magnetization is better than that of non-magnetization; it is observed that the formation rate of magnetized flocs is fast and dense, the sedimentation performance is good, and the sludge volume is very small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com