Nanometer impression device and nanometer impression method for high-brightness light-emitting diode (LED) graphics

A nano-imprinting and patterning technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for information processing, can solve the problems of mold damage, difficulty in large-area demoulding, high cost, etc., and achieve the goal of reducing imprinting defects Effects of production, good conformal contact capability, solution lifetime and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

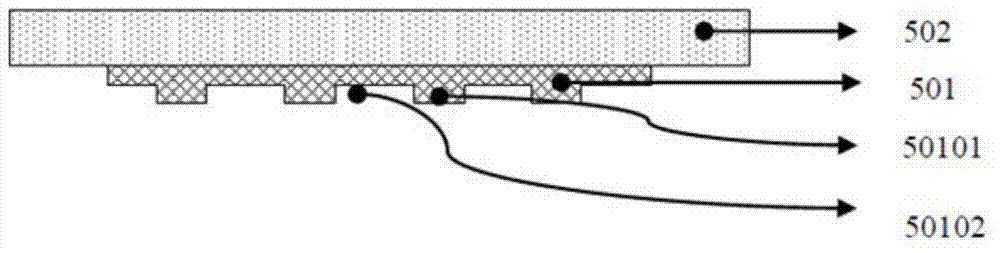

[0072] The present invention is an embodiment with the nano-patterned 4-inch sapphire substrate, the substrate 3 is a 4-inch sapphire, the graphic layer 501 of the film-like composite elastic soft mold selects water-soluble polymer polyvinyl alcohol (polyvinyl alcohol, PVA), and the supporting layer 502 uses highly transparent and elastic film-like PET material.

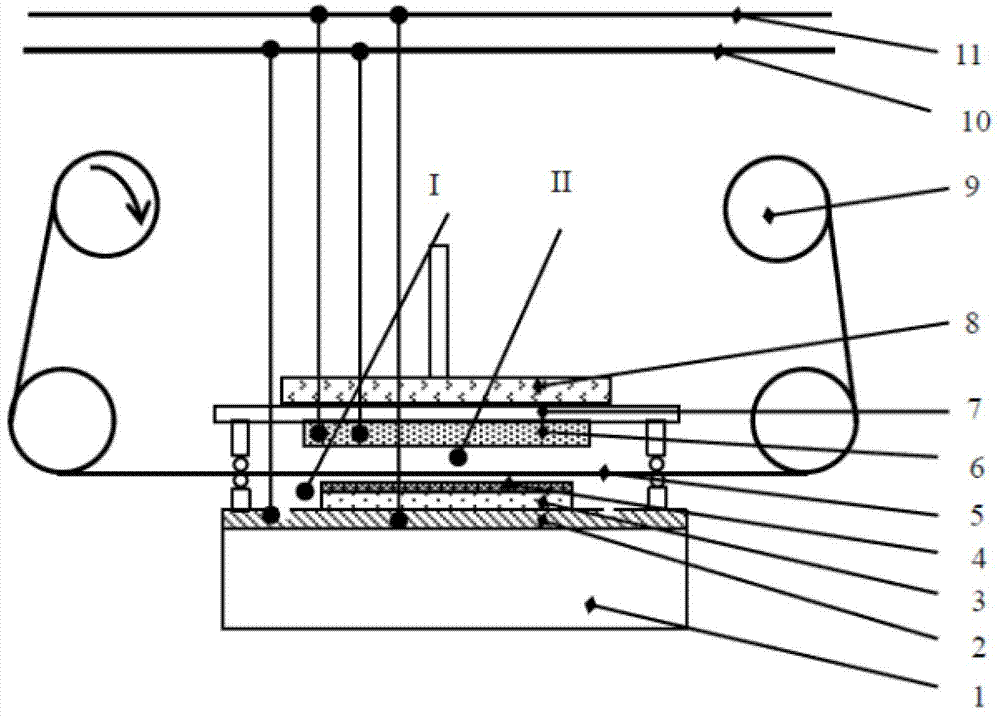

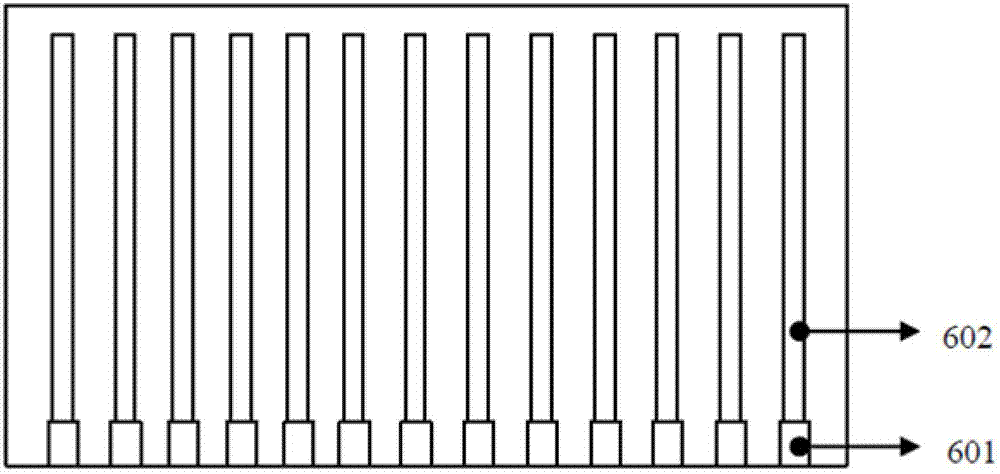

[0073] figure 1It is a schematic structural diagram of the nanoimprinting device used for high-brightness LED patterning in the present invention, which includes: a substrate 1, a vacuum chuck 2, a substrate 3, a UV-curable nanoimprinting resist 4, a mold 5, and a gas Valve plate 6, embossing mechanism 7, ultraviolet light source 8, mold feeding mechanism 9, vacuum pipeline 10, pressure pipeline 11; among them, the substrate 3 coated with UV-curable nanoimprint resist 4 is adsorbed On the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com