Formation method of lithium ion battery

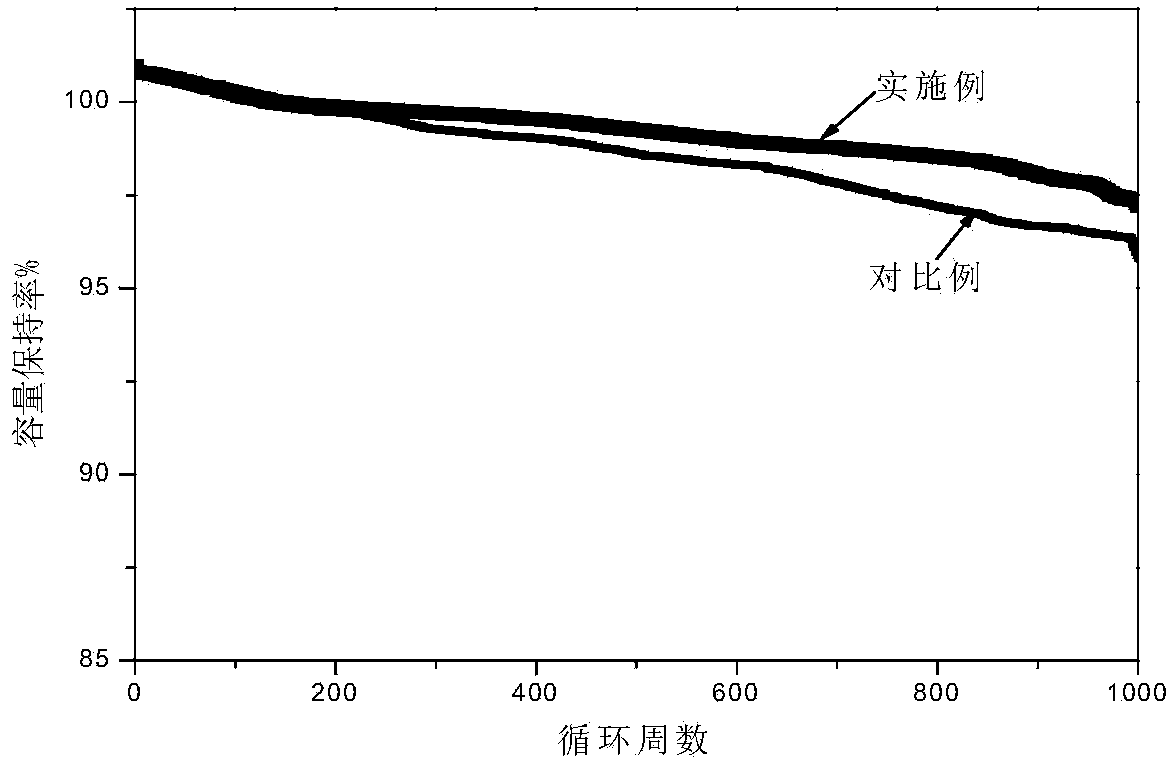

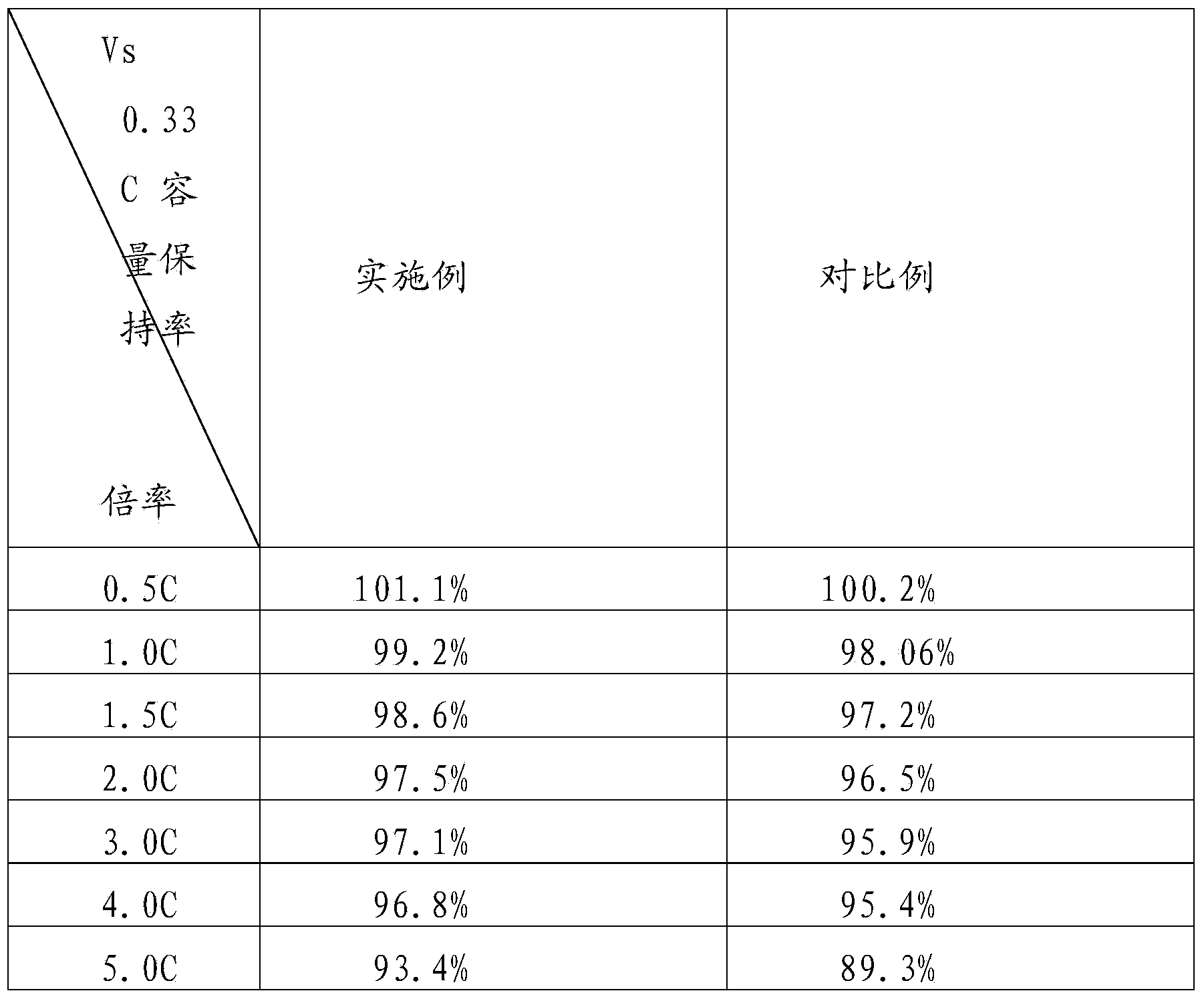

A technology of lithium-ion batteries and formation methods, which is applied in the field of formation of lithium-ion batteries, can solve the problems of battery capacity loss, safety hazards of piercing the diaphragm, and reduction of discharge capacity, etc., and achieve the effect of improving cycle and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

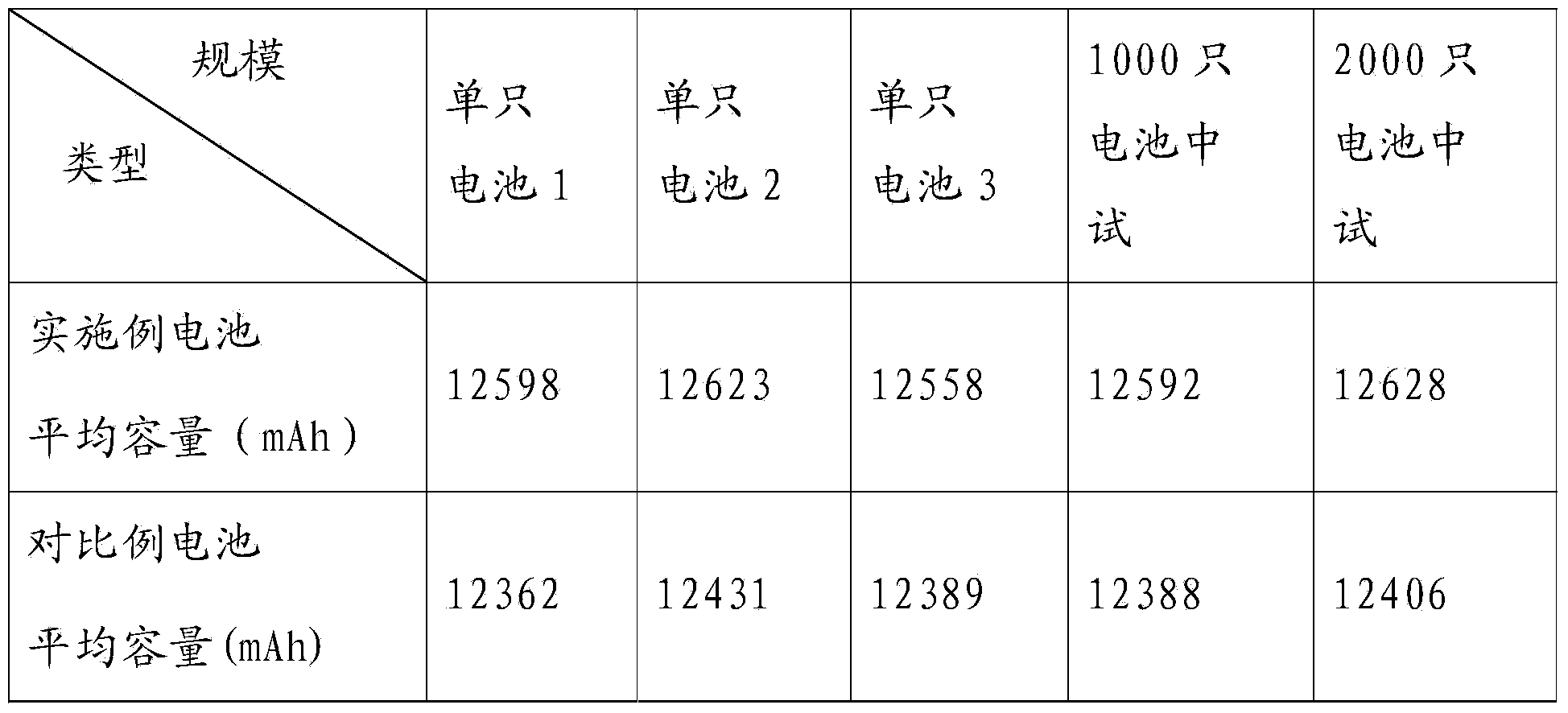

[0026] Take the formation of 12.5Ah lithium iron phosphate lithium ion battery as an example. Specifically include the following steps:

[0027] (1) Control the internal pressure of the battery case at -0.02MPa, and charge it with a constant current of 0.04C (500mA) for 150min (charge 10% of the nominal capacity);

[0028] (2) Charge it with a constant current of 0.2C (2500mA) for 240min (charge 80% of the nominal capacity), so that the battery is initialized to a total capacity of 90% SOC;

[0029] (3) Stand still for 4 minutes;

[0030] (4) Discharge it with a constant current of 0.2C (2500mA) to 2.0V;

[0031] (5) Stand still for 4 minutes;

[0032] (6) Charge it with a constant current of 0.5C (6250mA) for 108min (charging 90% of the nominal capacity);

[0033] (7) Then charge with a current of 0.04C (500mA) to 3.65V, then switch to constant voltage charging, and stop when the current drops to 0.02C (250mA).

Embodiment 2

[0035] Take the formation of 20Ah lithium iron phosphate lithium ion battery as an example. Specifically include the following steps:

[0036] (1) Control the internal pressure of the battery case at -0.03MPa, and charge it with a constant current of 0.2C (4000mA) for 30 minutes (charged with 10% of the nominal capacity);

[0037] (2) Charge it with a constant current of 1.0C (20000mA) for 42 minutes (charge 70% of the nominal capacity), so that the battery is initialized to a total capacity of 80% SOC;

[0038] (3) Stand still for 5 minutes;

[0039] (4) Discharge it with a constant current of 0.6C (12000mA) to 2.0V;

[0040] (5) Stand still for 5 minutes;

[0041] (6) Charge it with a constant current of 1.0C (20000mA) for 48 minutes (charging 80% of the nominal capacity);

[0042] (7) Then charge with a current of 0.2C (4000mA) to 3.65V, then switch to constant voltage charging, and stop when the current drops to 0.02C (400mA).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com