First-time charging forming method for lithium-ion secondary battery

A technology of secondary battery and chemical formation method, applied in secondary battery charging/discharging, secondary battery repair/maintenance, non-aqueous electrolyte storage battery, etc., to ensure cycle life and safety performance, improve cycle performance, and avoid negative electrode lithium precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

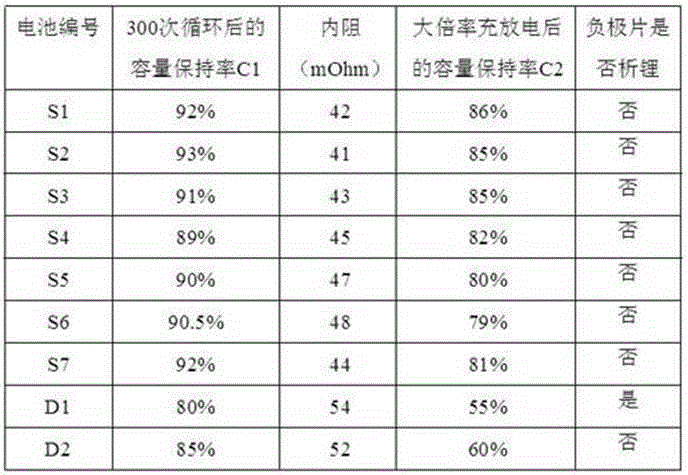

Examples

Embodiment 1

[0018] Embodiment 1, a kind of lithium ion secondary battery that this embodiment provides the initial charge formation method, comprises the following steps: the first step, the lithium ion secondary battery that has been filled with electrolyte is heated at a temperature of 20°C and relative humidity Aged for 12 hours in an environment less than or equal to 10%, and then charged to 2.5V with a constant current rate of 0.01C at a negative pressure of -0.085MPa, and then charged to 3.2V with a constant current rate of 0.05C. Then charge to 3.6V with a constant current at a rate of 0.1C, and seal the battery when the voltage reaches 3.6V.

[0019] In the second step, the sealed battery is aged at 50°C for 24 hours, then charged to 4.0V with a constant current rate of 0.5C, then charged to 4.2V with a rate of 0.2C, and finally charged at 4.2V Under constant voltage charging, the charging cut-off current is 100mA.

Embodiment 2

[0020] Embodiment 2, a method for forming a lithium-ion secondary battery for the first time provided by this embodiment, comprises the following steps: the first step, the lithium-ion secondary battery that has been injected with electrolyte is heated at a temperature of 70°C and a relative humidity Aged for 24 hours in an environment less than or equal to 10%, and then charged at a rate of 0.02C to 2.5V at a constant current rate of 0.02C, and then charged to 3.2V at a rate of 0.07C under a negative pressure of -0.092MPa. Then charge it to 3.6V with a constant current at a rate of 0.15C, and seal the battery when the voltage reaches 3.6V.

[0021] In the second step, the sealed battery is aged at 70°C for 72 hours, then charged to 3.9V with a constant current rate of 0.7C, then charged to 4.2V with a rate of 0.3C, and finally charged at 4.2V Under constant voltage charging, the charging cut-off current is 10mA.

Embodiment 3

[0022] Embodiment 3, a method for forming a lithium-ion secondary battery for the first time provided in this embodiment, comprises the following steps: the first step, the lithium-ion secondary battery that has been injected with electrolyte is heated at a temperature of 50°C and a relative humidity Aged for 18 hours in an environment less than or equal to 3%, and then charged to 2.5V with a constant current rate of 0.03C at a negative pressure of -0.090MPa, and then charged to 3.2V at a rate of 0.1C. Then charge it to 3.6V with a constant current at a rate of 0.2C, and seal the battery when the voltage reaches 3.6V.

[0023] In the second step, the sealed battery is aged at 10°C for 48 hours, then charged to 3.8V at a rate of 1C, and then charged to 4.2V at a rate of 0.5C, and finally charged at 4.2V Constant voltage charging, charging cut-off current is 200mA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com