Accurate automatic excavating device for model test

A model test and accurate technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve problems such as difficulty in simulating automatic excavation, difficult excavation depth, and high accuracy of model test, so as to achieve the effect of reducing human disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

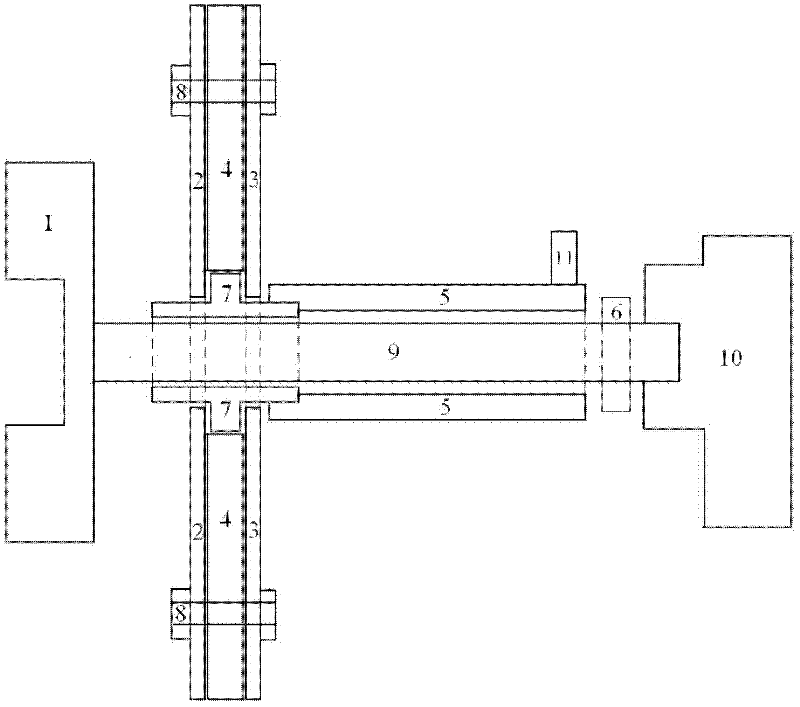

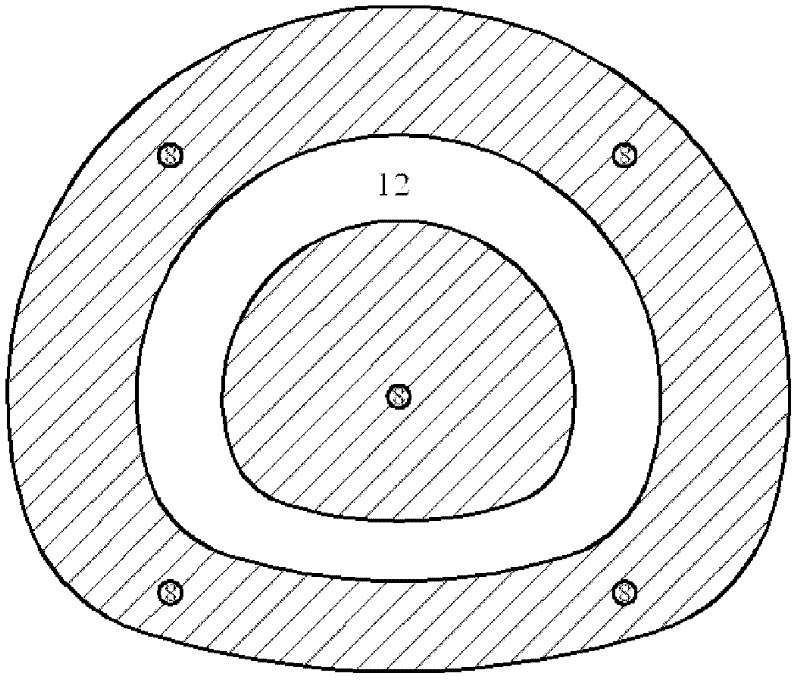

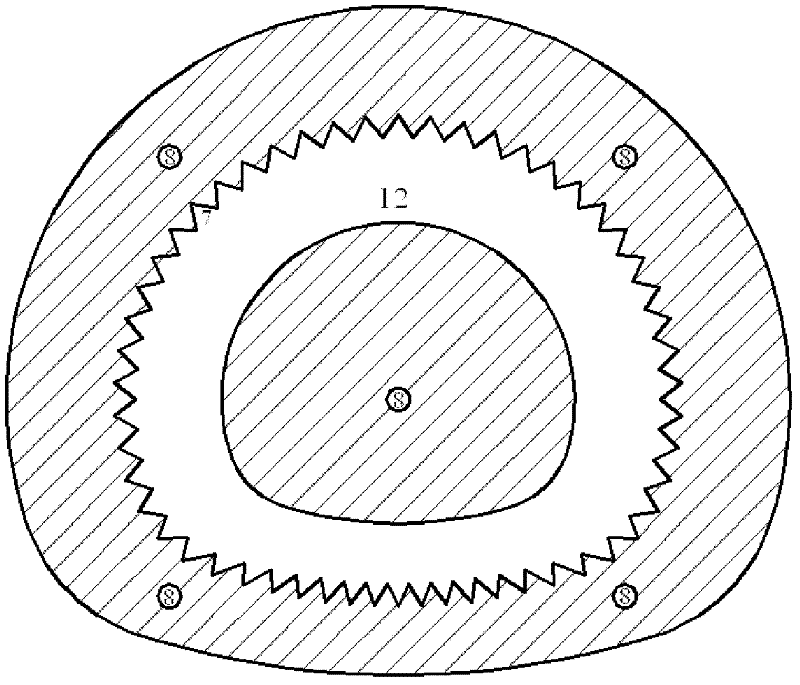

[0028] figure 1 Among them, a precise automatic excavation device for underground engineering model tests, including an excavation tool 1 of low-strength similar materials capable of simultaneously cutting the front and periphery, the tool 1 is connected to a transmission rod 9, and the end of the transmission rod 9 is connected to a power system 10, Power is provided by a small wind turbine. There is a hole control device behind the tool 1 (composed of hole-shaped control panel steel plate I 2, hole-shaped control panel steel plate II 3, hole-shaped control panel steel plate III 4, gear 7, bolt 8, and tool movement track 12), the hole-shaped control device There is a control tool movement track 12 on the device, and a gear 7 on the tool movement track 12 controls the rotation of the tool 1 through meshing. The gear 7 is connected with the sleeve 5 out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com