Method for preparing ultra-high-temperature thermal-insulation Yb3Al5O12ceramic component

A technology of yb3al5o12, ceramic components, applied in the field of ultra-high temperature heat-insulating ceramics, achieving the effects of high purity, low thermal conductivity, and optimized preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

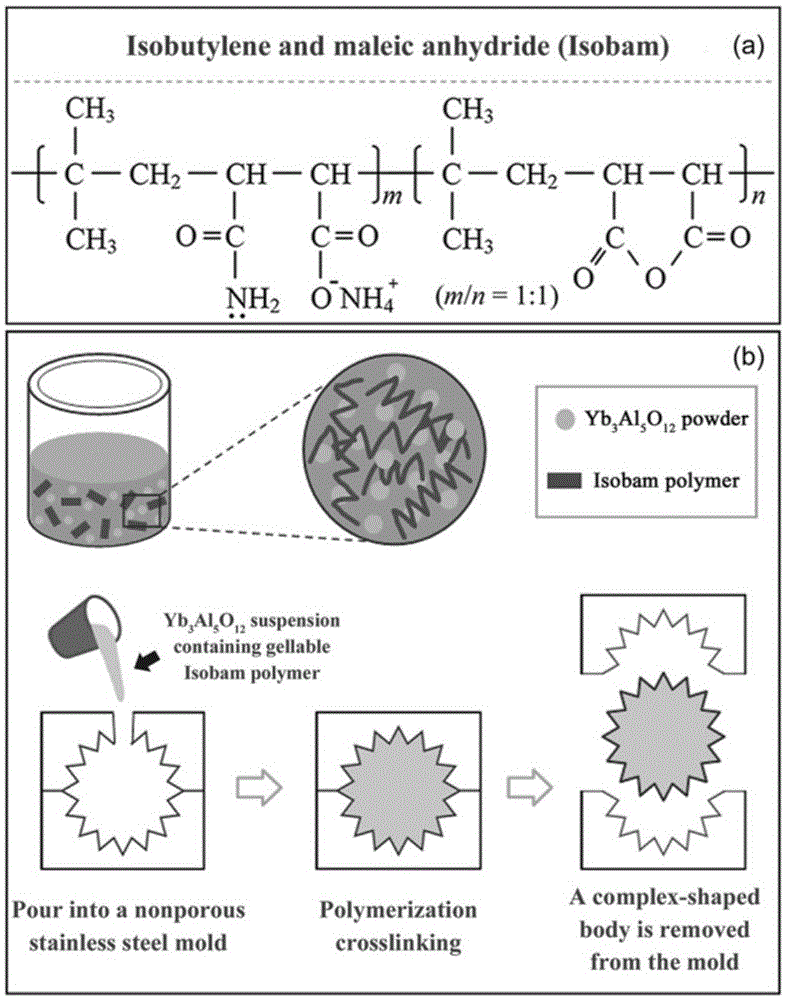

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation ultra-high temperature insulation Yb described in the present invention 3 Al 5 o 12 A method for a ceramic element, comprising the steps of:

[0031] (1) Change Yb 2 o 3 and Al 2 o 3 Powder according to Yb 2 o 3 :Al 2 o 3 =3.01:5 molar ratio weighing, adding absolute ethanol, mixing with a drum mixer for 48 hours, the rotating speed is 80 / rev, and the uniformly mixed raw materials are dried at 20°C for 24 hours to obtain Yb 2 o 3 and Al 2 o 3 Mix the powder, dry the Yb after treatment 2 o 3 and Al 2 o 3 The mixed powder is placed in a molybdenum disilicide furnace, heated to 1050°C in the air, and kept for 4 hours to obtain the main phase as Yb 3 Al 5 o 12 Ultra-high temperature insulation ceramic powder.

[0032] (2) take dehydrated alcohol as medium with the Yb of step (1) gained with planetary ball mill ball mill 3 Al 5 o 12 The ceramic powder was ball milled for 36 hours at a speed of 200 rpm to obtain Yb with a particle ...

Embodiment 2

[0037] A kind of preparation ultra-high temperature insulation Yb described in the present invention 3 Al 5 o 12 A method for a ceramic element, comprising the steps of:

[0038] (1) Change Yb 2 o 3 and Al 2 o 3 Powder according to Yb 2 o 3 :Al 2 o 3 =3.02:5 molar ratio weighing, adding absolute ethanol, mixing with a drum mixer for 36 hours, the rotating speed is 100 / rev, and drying the uniformly mixed raw materials at 35°C for 12 hours to obtain Yb 2 o3 and Al 2 o 3 Mix the powder, dry the Yb after treatment 2 o 3 and Al 2 o 3 The mixed powder is placed in a molybdenum disilicide furnace, heated to 1250°C in the air, and kept for 2 hours to obtain high-purity Yb 3 Al 5 o 12 Ultra-high temperature insulation ceramic powder.

[0039] (2) take absolute ethanol as the medium and use planetary ball mill ball mill to Yb 3 Al 5 o 12 The ceramic powder was ball milled for 24 hours at a speed of 300 rpm to obtain Yb with a particle size of less than 1 μm 3 Al ...

Embodiment 3

[0042] A kind of preparation ultra-high temperature insulation Yb described in the present invention 3 Al 5 o 12 A method for a ceramic element, comprising the steps of:

[0043] (1) Change Yb 2 o 3 and Al 2 o 3 Powder according to Yb 2 o 3 :Al 2 o 3 =3.03:5 molar ratio weighing, adding absolute ethanol, mixing with a drum mixer for 30 hours, the rotating speed is 150 / rev, and drying the uniformly mixed raw materials at 40°C for 12 hours to obtain Yb 2 o 3 and Al 2 o 3 Mix the powder, dry the Yb after treatment 2 o 3 and Al 2 o 3 The mixed powder is placed in a molybdenum disilicide furnace, heated to 1350°C in the air, and kept for 1 hour to obtain high-purity Yb 3 Al 5 o 12 Ultra-high temperature insulation ceramic powder.

[0044] (2) take absolute ethanol as the medium and use planetary ball mill ball mill to Yb 3 Al 5 o 12 The ceramic powder was ball milled for 30 hours at a speed of 280 rpm to obtain Yb with a particle size of less than 1 μm 3 Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com