Phosphor coating method and LED device

A technology of light-emitting diodes and phosphors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor light color consistency, low product repetition rate, uneven light field distribution, etc., and achieve the effect of uniform light field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

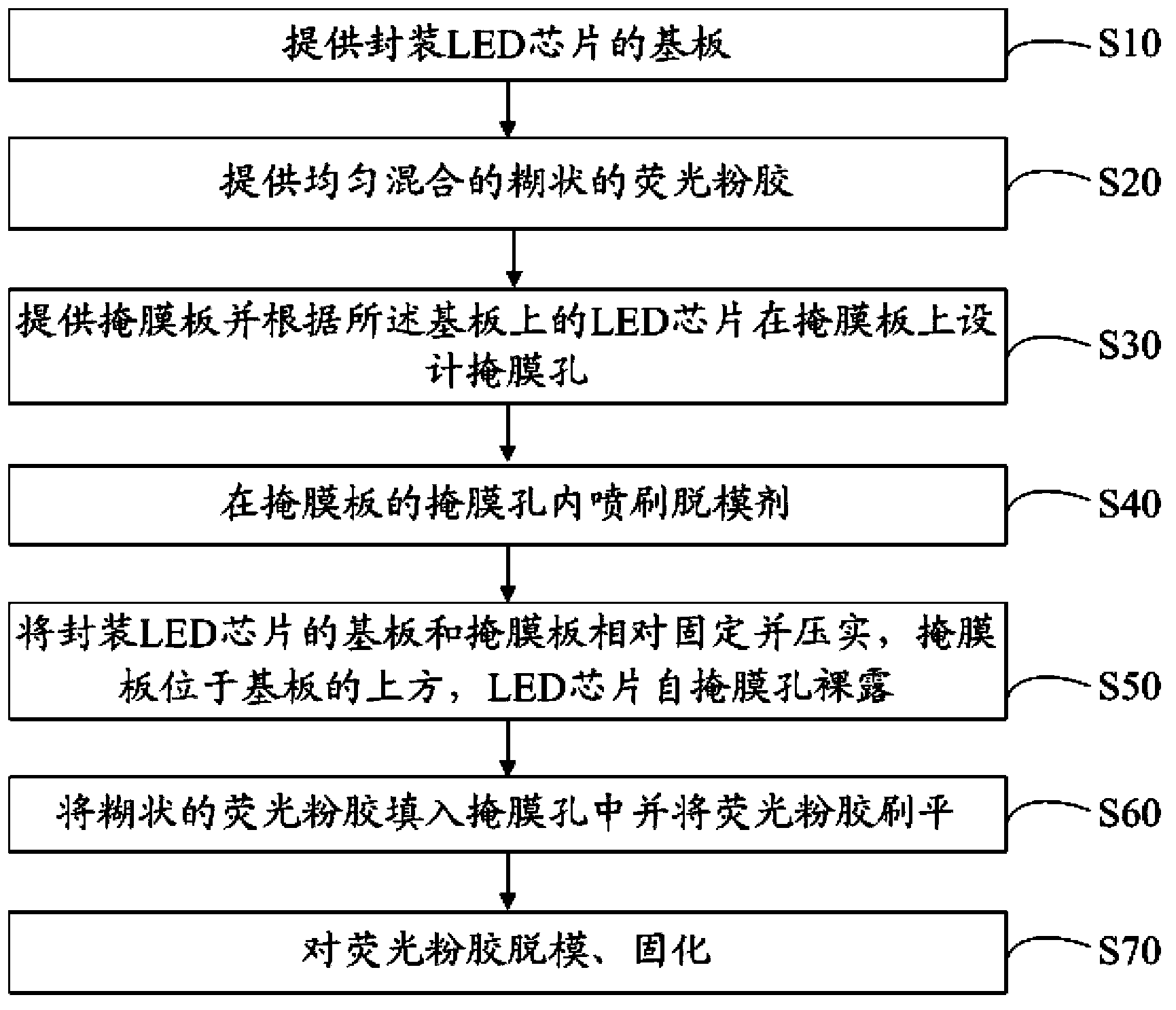

no. 1 approach

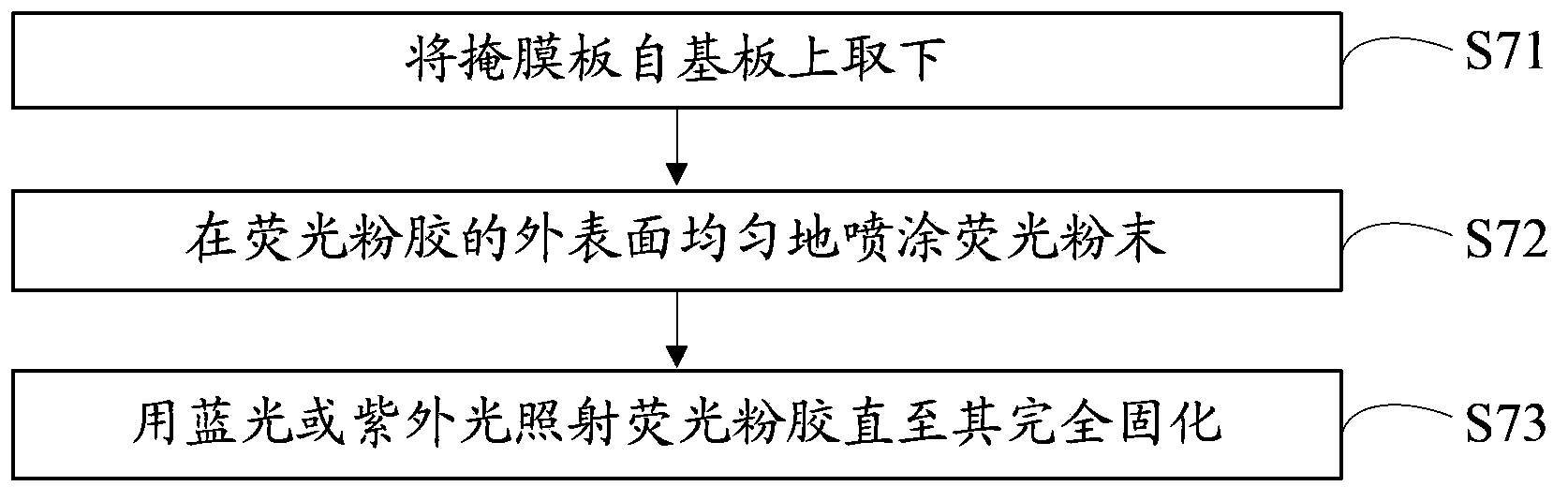

[0045] Please also refer to figure 2 , figure 2 It is a flow chart of the first embodiment of the demoulding and curing of phosphor glue in the phosphor coating method of the present invention, including the following steps:

[0046] S71, removing the mask plate 30 from the substrate 10;

[0047] S72, spraying phosphor powder evenly on the outer surface of the phosphor powder glue;

[0048] S73, irradiating the phosphor glue with blue light or ultraviolet light or heating the phosphor glue until it is completely cured.

[0049] The length of UV curing time is related to the colloid used, and a typical value in practical application is 30 seconds. Direct heating and curing is carried out by placing the phosphor glue in a vacuum oven. The heating temperature is generally 150 degrees Celsius and the heating time is 1 hour.

[0050] In this embodiment, the method of demoulding and then curing is adopted for the fluorescent powder glue brushed on the outside of the LED chip, wh...

no. 2 approach

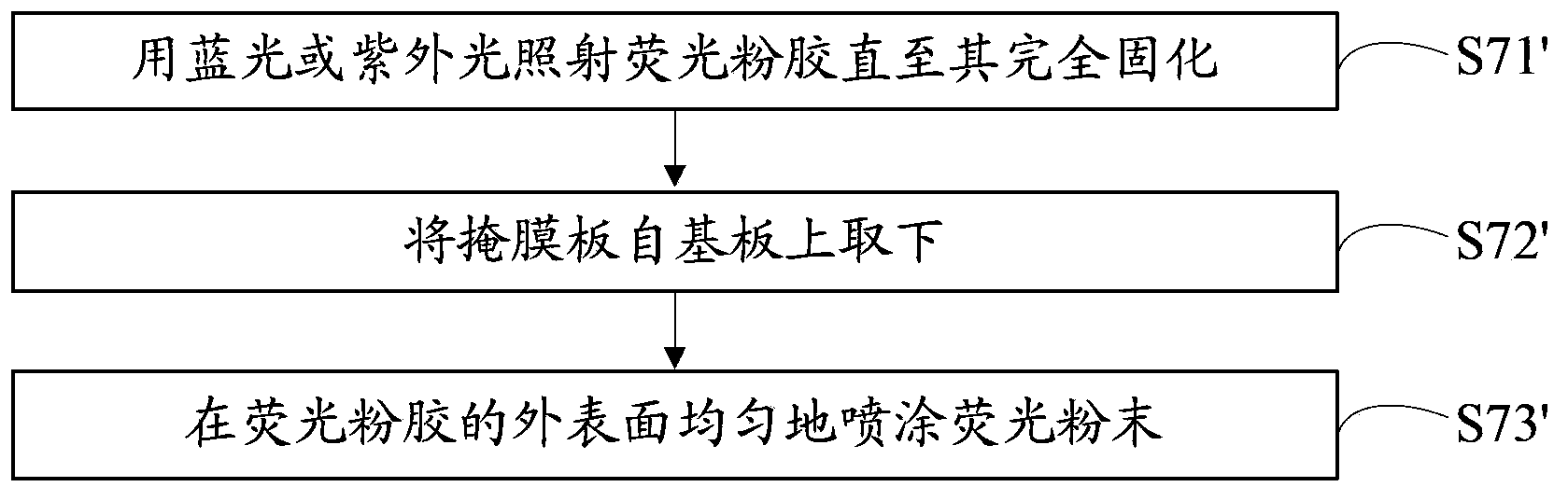

[0054] Please also refer to image 3 , image 3 It is a flow chart of the second embodiment of the demoulding and curing of phosphor glue in the phosphor coating method of the present invention, including the following steps:

[0055] S71', irradiating the phosphor glue with blue light or ultraviolet light until it is completely cured;

[0056] S72', the mask plate is taken off from the substrate;

[0057] S73', spraying fluorescent powder evenly on the outer surface of the fluorescent powder glue.

[0058] In this embodiment, the method of first curing and then demolding the phosphor glue brushed on the outside of the LED chip is applicable to the situation where relatively thin phosphor glue (that is, with a low viscosity coefficient) is prepared through step S20.

[0059] When the viscosity coefficient of the phosphor colloid is low, the phosphor colloid brushed on the outside of the LED chip through the mask plate is easy to flow, and it is not suitable for demoulding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com