3D printing-based prism film preparation method and device thereof

A 3D printing and preparation device technology, which is applied to flat products, household utensils, and other household utensils, can solve problems such as complicated procedures, stretching technology, and film thickness control problems, and achieve simplified preparation procedures, strong practicability, and improved Effect of Surface Cleanliness and Precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] The prism film preparation method based on 3D printing of the present invention comprises the following steps:

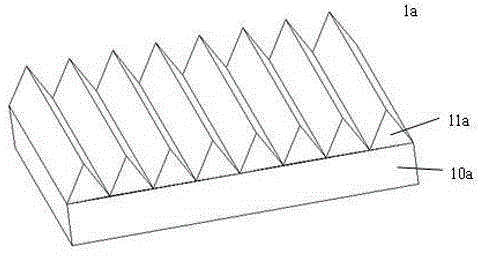

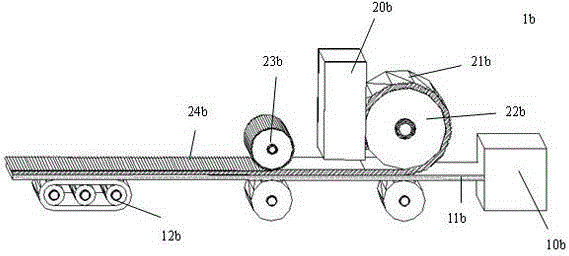

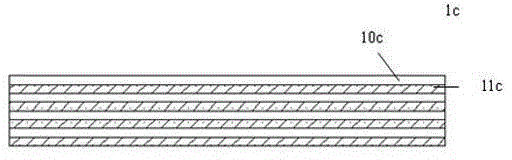

[0035] Step S1. Establish a three-dimensional digital model of the prism film and convert it into work instructions for controlling the operation of the 3D printing device, including a first instruction for printing the base layer of the prism film and a second instruction for printing the prism layer of the prism film.

[0036] Step S2. Put the first raw material for printing the base layer into the feeding chamber of the 3D printing device. The first raw material for printing the base layer is PET polyester. Use melting technology to convert the first raw material into a liquid state, and set the melting temperature at 255- 260°C; 3D printing equipment receives and works according to the first instruction, the print head spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com