3D printing-based reflective polarizing film preparation method and device thereof

A 3D printing and preparation device technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of stretching technology and control film thickness, complicated processes, etc., to achieve strong practicability, simplify the preparation process, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] The preparation method of reflective polarizing film based on 3D printing of the present invention comprises the following steps:

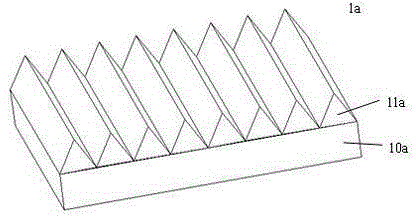

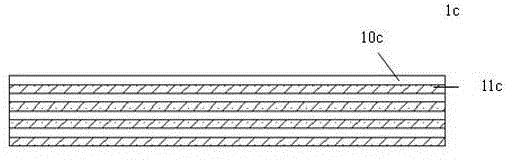

[0035] Step S1, establish a three-dimensional digital model of the reflective polarizing film, and convert it into a work instruction for controlling the work of the 3D printing device, including the first instruction for printing the first refractive index film of the reflective polarizing film and the second instruction for printing the reflective polarizing film. Second instruction for refractive index films.

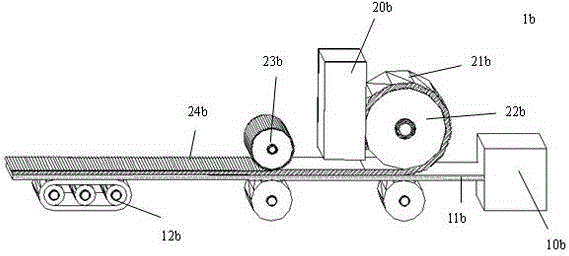

[0036] Step S2, put the first raw material for printing the first refractive index film and the second raw material for printing the second refractive index film into the feeding chamber of the 3D printing device respectively, and convert the first raw material and the second raw material into a li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com