Cover plate, display panel and preparation method of display panel

A technology of display panel and cover plate, which is applied to instruments, identification devices, etc., can solve the problems affecting the performance of the display panel, poor fit, etc., to achieve the effect of precise shape control, avoid bonding bubbles, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

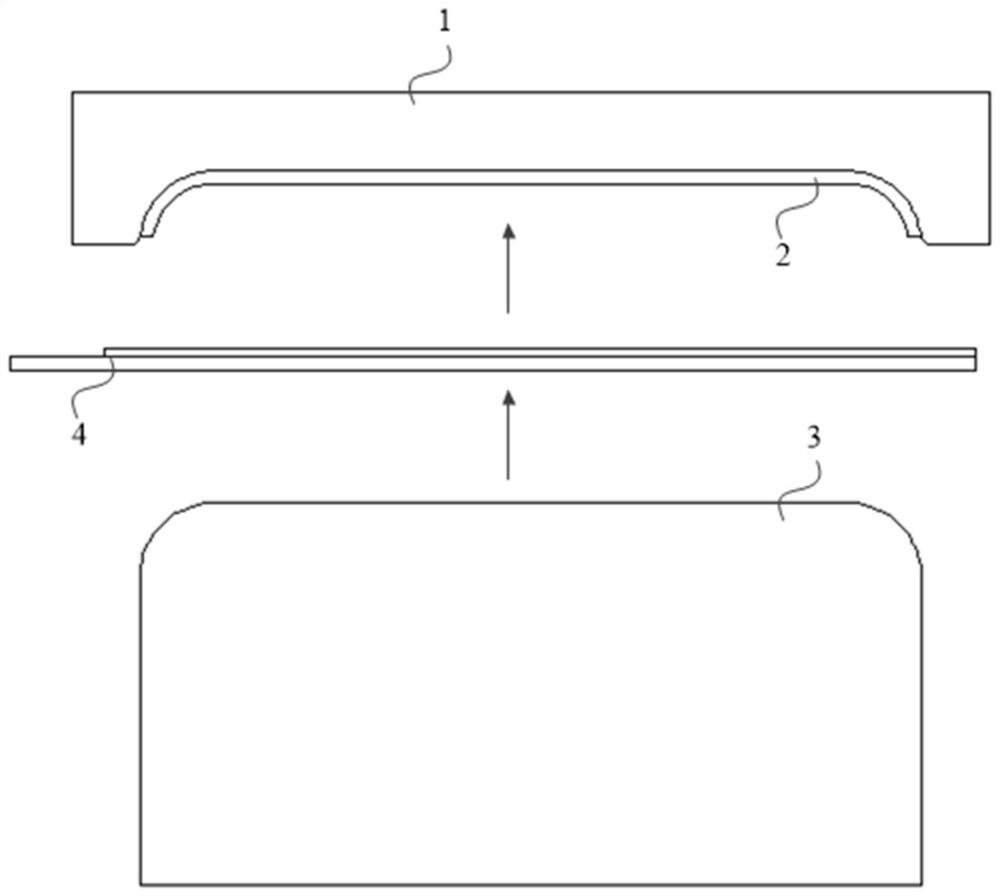

[0068] In the field of display technology, curved screen display panels are more and more widely used. figure 1 It is a schematic diagram of an AMOLED screen body and a glass cover in the bonding stage in the related art, as shown in figure 1 As shown, a suction cup 1 is used to fix the curved glass cover 2 , and then a silicone pad 3 is used to press the flat AMOLED screen 4 and the glass cover 2 to realize the bending of the edge of the AMOLED screen 4 . However, in the bonding process of the current curved screen display panel, since the glass cover is a curved surface, after pressing the flat AMOLED screen and the glass cover, due to the uneven force on the AMOLED screen as a whole, it is easy to appear on the curved surface. Fit bubbles, and because of insufficient bonding pressure, it is easy to make the optical glue and the glass cover insufficiently bonded, resulting in poor bonding, especially when the AMOLED screen is bonded to the large curvature glass cover or mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com