Low-heat-expansion high-intensity alumina-silicon-aluminum (AlN-Si-Al) mixed composite material and preparation method thereof

A technology of low thermal expansion and composite materials, which is applied in the field of AlN-Si-Al hybrid composite materials and their preparation, hybrid composite materials and their preparation, and can solve the problems of metal aluminum non-wetting, difficulty, and poor powder sintering performance. Achieve the effects of promoting rearrangement, realizing engineering production, and high-strength machining process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The hybrid composite material prepared in this example is 10wt.% AlN-40wt.% Si-Al, that is, the content of AlN is 10wt.%, the content of Si is 40wt.% Si, and the content of Al is 50wt.%. Its preparation method adopts following technical scheme:

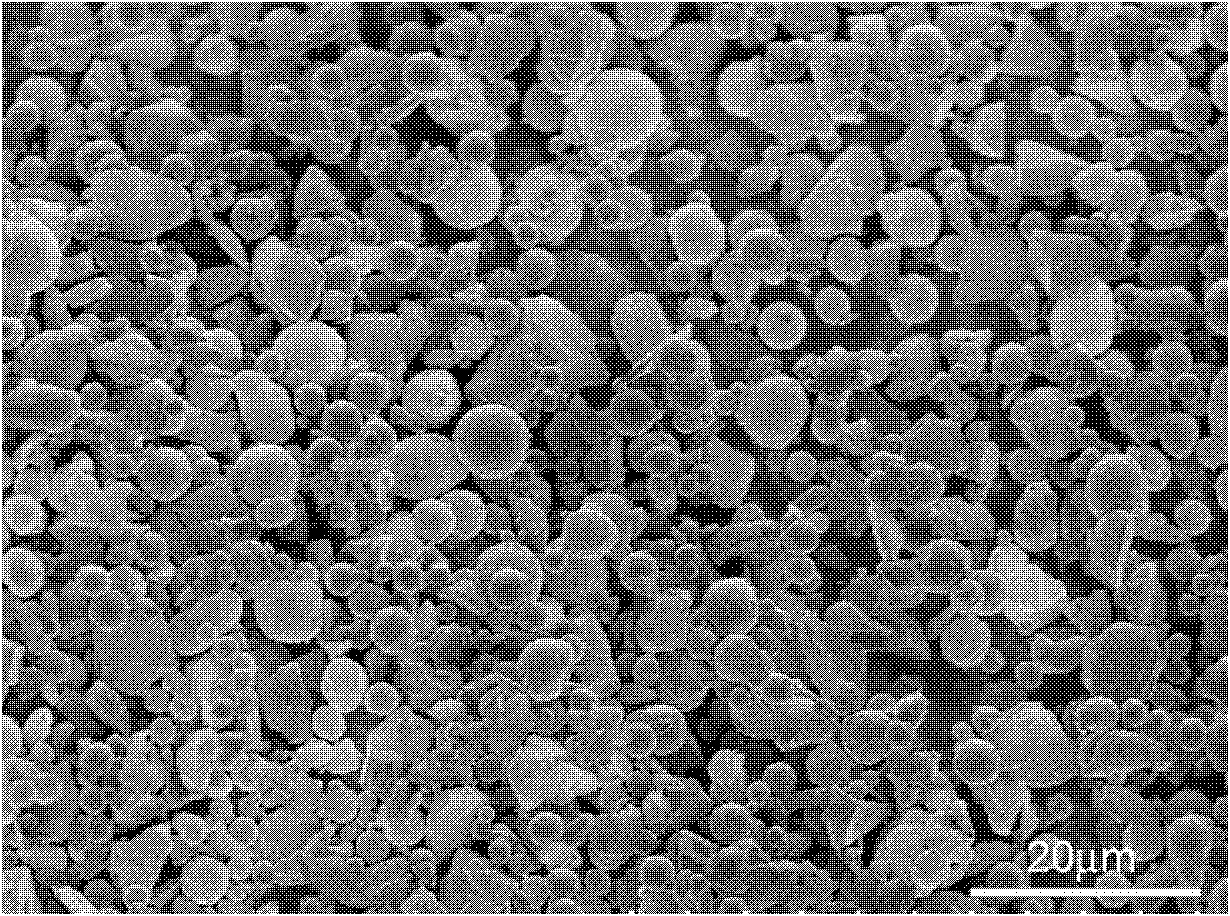

[0040] The pure Al powder, AlN powder and Si powder are uniformly mixed in a conical mixing tank according to the mass ratio of the three powders of 5:1:4 to form AlN-Si-Al mixed powder. For the particle dispersion characteristics of the mixed powder, see figure 1 Shown, so that the mass fraction of AlN is 10wt.%, the mass fraction of Si is 40wt.%, adopts φ 5mm stainless steel ball as the powder mixing medium, the ball material ratio is 1: 1, and the powder mixing time is 14 hours; The average particle size of pure Al powder, AlN powder and Si powder (d0.5, that is, more than 50wt.% of the powder particle size is smaller than this size) is 8.5 μm, 9 μm, and 15 μm respectively; the size of the mixed powder is φ90mm×260mm Cold i...

Embodiment 2

[0043] The hybrid composite material prepared in this example is 25wt.% AlN-45wt.% Si-Al, that is, the content of AlN is 25wt.%, the content of Si is 45wt.% Si, and the content of Al is 30wt.%. Its preparation method adopts following technical scheme:

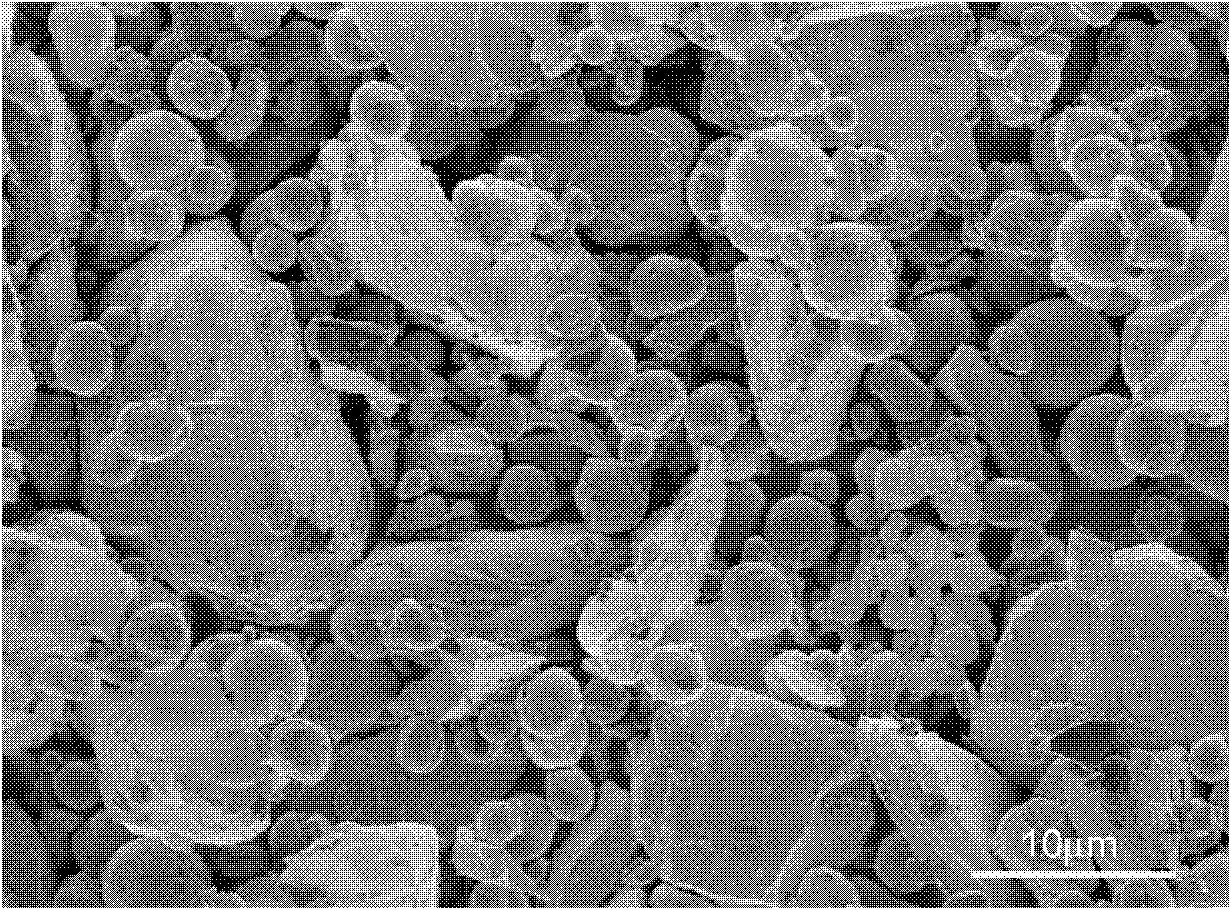

[0044] Pure Al powder, AlN powder and Si powder were uniformly mixed in a conical mixing tank according to the mass ratio of the three powders of 1.2:1:1.8 to form AlN-Si-Al mixed powder (for the particle dispersion characteristics of the mixed powder, see figure 2 Shown), so that the massfraction of AlN is 25wt.%, the massfraction of Si is 45wt.%, adopts φ5mm stainless steel ball as the powder mixing medium, the ball material ratio is 1: 1, and the powder mixing time is 20 hours; The average particle sizes of pure Al powder, AlN powder and Si powder are 3 μm, 4.5 μm and 9 μm respectively; the mixed powder is put into a rubber sheath with a size of φ84mm×260mm and cold isostatically pressed to form at a pressure of 200MPa. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com