Preparation method of titanium-chromium alloy sputtering target material for magnetic recording

A technology for sputtering target material and magnetic recording, which is applied in sputtering plating, metal material coating process, ion implantation plating, etc. The composition is uniform, the grain size is small, and the effect of ensuring product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

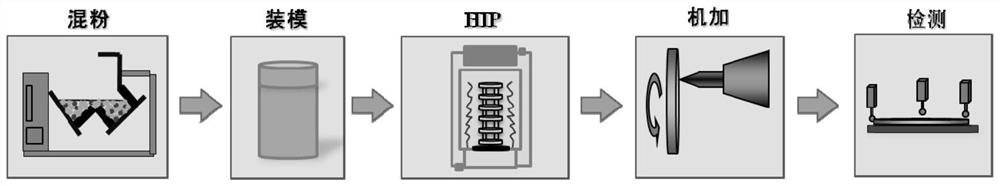

[0034] This embodiment provides a method for preparing a titanium-chromium alloy sputtering target for magnetic recording, the preparation method comprising:

[0035] Chromium powder and titanium powder are mixed in a V-type powder mixer under an argon atmosphere, the content of titanium powder in the mixed powder is 95at%, the rotating speed of the V-type powder mixer is 5rpm, and the mixing time is 32h, the pressure of the protective gas was 0.02MPa, and the mixed powder was obtained; the mixed powder was put into a stainless steel sheath, and degassed at 300°C for 8h, and the vacuum degree in the mold after the degassing was 3.0×10 -3 Pa, after degassing, perform hot isostatic pressing at 600° C. and 90 MPa for 6 hours to obtain the titanium-chromium alloy sputtering target. The titanium-chromium alloy sputtering target is machined, detected, cleaned and packaged to obtain a product.

Embodiment 2

[0037]Chromium powder and titanium powder are mixed in V-type powder mixer under argon atmosphere, the content of titanium powder in the mixed powder is 13at%, the rotating speed of described V-type powder mixer is 15rpm, and the time of described mixing is 18h, the pressure of the protective gas was 0.06MPa, and the mixed powder was obtained; the mixed powder was put into a stainless steel sheath, and degassed at 600°C for 4h, and the vacuum degree in the mold after the degassing was 1.0×10 -3 Pa, after degassing, perform hot isostatic pressing at 1200° C. and 170 MPa for 3 hours to obtain the titanium-chromium alloy sputtering target. The titanium-chromium alloy sputtering target is machined, detected, cleaned and packaged to obtain a product.

Embodiment 3

[0039] Chromium powder and titanium powder are mixed in V-type powder mixer under argon atmosphere, the content of titanium powder in the mixed powder is 50at%, the rotating speed of described V-type powder mixer is 8rpm, and the time of described mixing is 24h, the pressure of the protective gas was 0.05MPa, and mixed powder was obtained; the mixed powder was put into a stainless steel sheath, and degassed at 500°C for 5h, and the vacuum degree in the mold after the degassing was 2.0×10 -3 Pa, after degassing, perform hot isostatic pressing at 1000° C. and 100 MPa for 5 hours to obtain the titanium-chromium alloy sputtering target. The titanium-chromium alloy sputtering target is machined, detected, cleaned and packaged to obtain a product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com