Fe-Cr base composite ceramic material and preparation method thereof

A composite ceramic, fe-cr technology, applied in the field of ceramic materials, can solve the problems of high brittleness, low toughness, and difficult cold working, etc., and achieve the effect of good machinability, simple process flow, and low expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

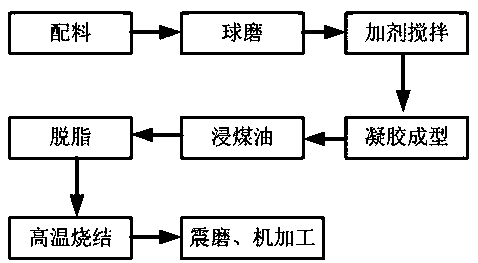

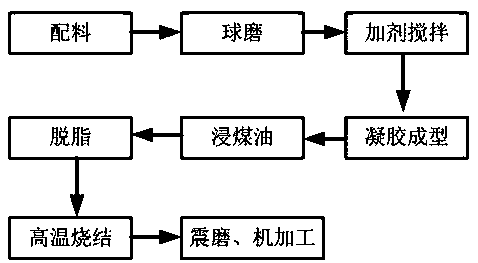

Method used

Image

Examples

Embodiment 1

[0017] According to the mass percentage, weigh 45% Fe powder, 35% Cr 2 o 3 Powder, 20% Al 2 o 3 powder, in which Fe powder has a purity of 99.9%, a particle size of 60nm, and Cr 2 o 3 The purity of the powder is 99.9%, the particle size is 50nm, Al 2 o 3 The purity of the powder is 95.0%, and the particle size is 50nm.

[0018] Fe powder, Cr 2 o 3 Powder and Al 2 o 3 Put the powder into a ball mill tank lined with polyurethane, add agate balls with a particle size of 20mm according to the ball-to-material ratio of 2, add Fe powder, Cr 2 o 3 Powder and Al 2 o 3 Deionized water with 0.8% of the total powder mass, the loading capacity of the ball milling tank is 75%, the ball milling speed is controlled to be 30 rpm, and ball milling is carried out for 30 hours; the slurry after ball milling is transferred to the stirring container, and the mass of the ball milling slurry is 10% methyl cellulose, set the stirring speed to 15 rev / min, while stirring, add suspending a...

Embodiment 2

[0020] According to the mass percentage, weigh 47% Fe powder, 38% Cr 2 o 3 Powder, 15% Al 2 o 3 powder, the purity of Fe powder is 99.9%, the particle size is 100nm, Cr 2 o 3 The purity of the powder is 99.9%, the particle size is 200nm, Al 2 o 3 The purity of the powder was 95.0%, and the particle size was 200 nm.

[0021] Fe powder, Cr 2 o 3 Powder and Al 2 o 3 Put the powder into a ball mill tank lined with polyurethane, add agate balls with a particle size of 22mm according to the ball-to-material ratio of 2, add Fe powder, Cr 2 o 3 Powder and Al 2 o 3 Deionized water with 0.8% of the total powder mass, the loading capacity of the ball milling tank is 75%, the ball milling speed is controlled to be 32 rpm, and the ball milling is carried out for 32 hours; the slurry after the ball milling is transferred to the stirring container, and the quality of the ball milling slurry 12% methyl cellulose, set the stirring speed to 18 rev / min, while stirring, add suspendi...

Embodiment 3

[0023] According to the mass percentage, weigh 50% Fe powder, 40% Cr 2 o 3 Powder, 10% Al 2 o 3 powder, in which Fe powder has a purity of 99.9%, a particle size of 150nm, and Cr 2 o 3 The purity of the powder is 99.9%, the particle size is 400nm, Al 2 o 3 The purity of the powder was 95.0%, and the particle size was 400 nm.

[0024] Fe powder, Cr 2 o 3 Powder and Al 2 o 3 Put the powder into a ball mill tank lined with polyurethane, add agate balls with a particle size of 25mm according to the ball-to-material ratio of 2, add Fe powder, Cr 2 o 3 Powder and Al 2 o 3 Deionized water with 0.8% of the total powder mass, the loading capacity of the ball milling tank is 75%, the ball milling speed is controlled to be 35 rpm, and the ball milling is carried out for 35 hours; the slurry after the ball milling is transferred to the stirring container, and the quality of the ball milling slurry 15% methyl cellulose, set the stirring speed to 20 rpm, while stirring, add su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com