Austenitic stainless steel medium plate for liquid hydrogen container and preparation method of austenitic stainless steel medium plate

An austenitic stainless steel, thick plate technology, applied in non-pressure vessels, gas/liquid distribution and storage, manufacturing tools, etc., can solve the problems of difficult storage and transportation, high cost, easy volatility, etc., and achieve low ferrite content , the effect of stable tissue properties, good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

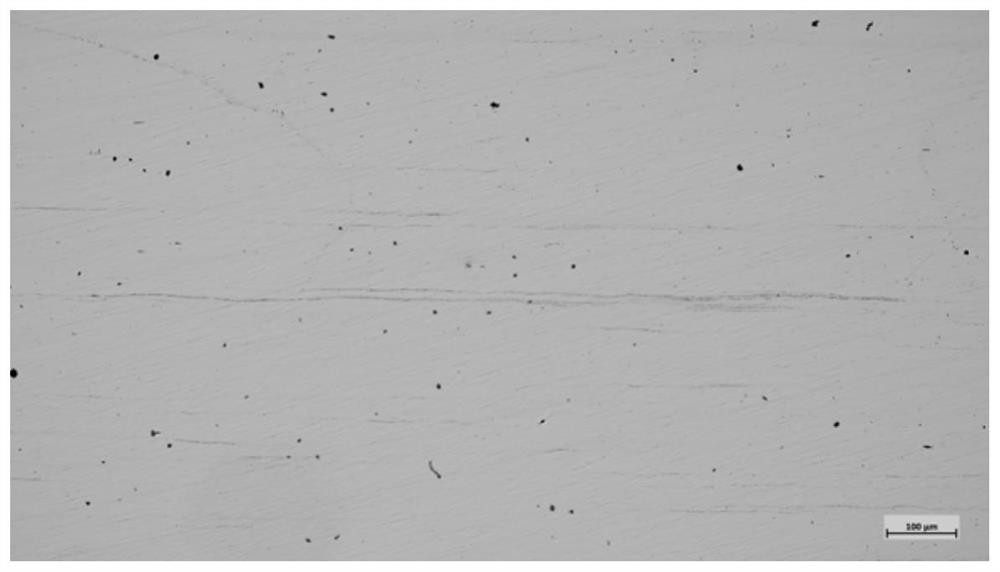

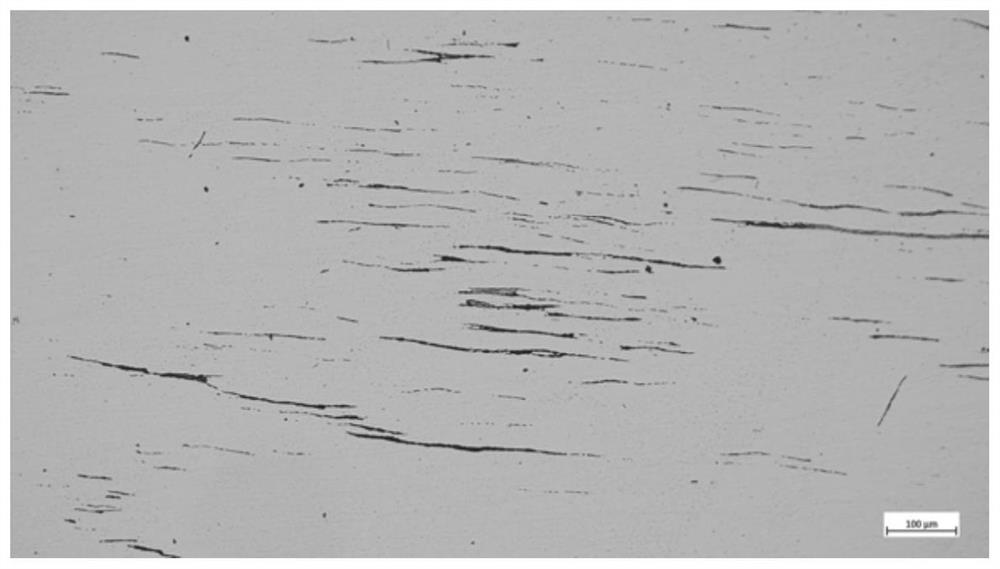

Examples

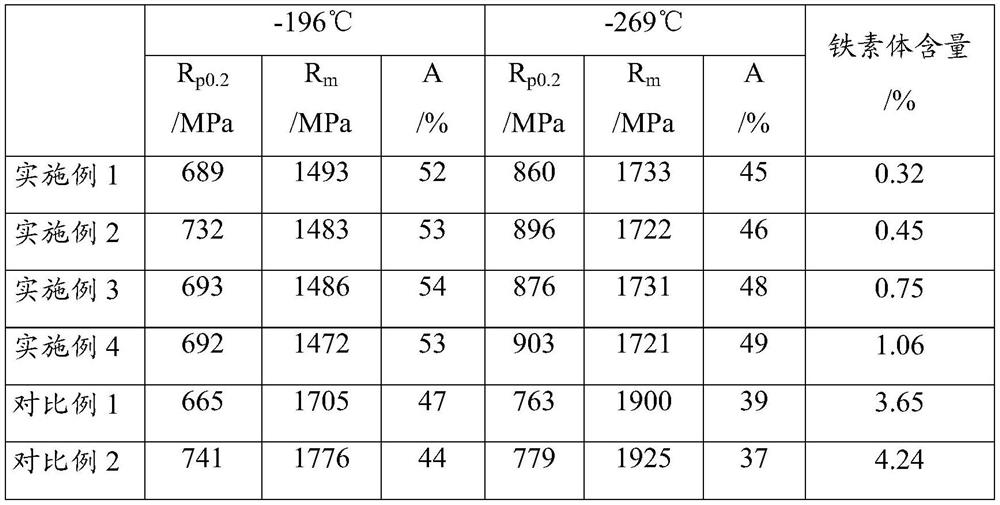

Embodiment 1

[0069] Table 1 shows the elemental composition of the austenitic stainless steel sheet of this example.

[0070] The preparation process of the austenitic stainless steel plate of the present embodiment is as follows:

[0071](1) Control the heating temperature of the continuous casting billet to 1250°C, control the total heating time according to 9h, cool it to 280°C naturally, and then use the 20# grinding wheel after grinding with the 16# grinding wheel, and the grinding rate is 1.5%. The ground slab is heated to 1260℃, and the heating time is controlled by 270min.

[0072] (2) Roll the continuous casting slab to a width of 2000mm with a pass deformation rate of 15% on the blooming mill, and then continue to roll it to a thickness of 42mm. The temperature of the rough rolling process is above 1100°C throughout the process. The finishing rolling unit starts rolling at a temperature of 1030 ℃, and the finishing rolling process does not use cooling water, and the thickness of...

Embodiment 2

[0076] Table 1 shows the elemental composition of the austenitic stainless steel sheet of this example.

[0077] The preparation process of the austenitic stainless steel plate of the present embodiment is as follows:

[0078] (1) Control the heating temperature of the continuous casting billet to 1260°C, control the total heating time according to 10h, and cool it to 260°C naturally. After grinding with a 16# grinding wheel, use a 20# grinding wheel for grinding, and the grinding rate is 2.0%. The ground slab was heated to 1265℃, and the heating time was controlled by 240min.

[0079] (2) On the blooming mill, the continuous casting slab is rolled to a width of 2200mm with a pass deformation rate of 15%, and then continues to be rolled to a thickness of 46mm. The temperature of the rough rolling process is above 1090℃. The finishing rolling unit starts rolling at a temperature of 1020 ℃, and cooling water is not used in the whole finishing rolling process, and the thickness ...

Embodiment 3

[0084] Table 1 shows the elemental composition of the austenitic stainless steel sheet of this example.

[0085] The preparation process of the austenitic stainless steel plate of the present embodiment is as follows:

[0086] (1) Control the heating temperature of the continuous casting billet to 1245°C, control the total heating time according to 10.5h, and cool it to 290°C naturally. The ground slab was heated to 1255℃, and the heating time was controlled by 245min.

[0087] (2) Roll the continuous casting slab to a width of 1800mm with a pass deformation rate of 15% on the blooming mill, and then continue to roll it to a thickness of 35mm. The temperature of the rough rolling process is above 1080°C. The finishing rolling unit starts rolling at a temperature of 1015°C. Cooling water is not used throughout the finishing rolling process, and the thickness of the rolled product is 9mm.

[0088] (3) The hot-rolled sheet is solution-treated in a normalizing furnace, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com