Thick-specification hot-rolled dual-phase steel plate and manufacturing method thereof

A thick-gauge, steel plate technology is applied in the field of low-cost, thick-gauge, and uniform hot-rolled dual-phase steel plates and in the field of manufacturing. Realize the effect of industrialized mass production, low alloy cost, and reduced dependence on alloying elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

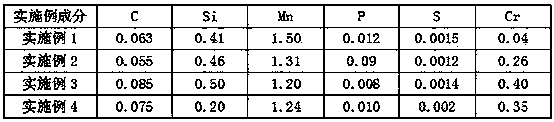

[0027] The following are specific examples of the present invention, which are used to explain the present invention, but not to limit the scope of the present invention.

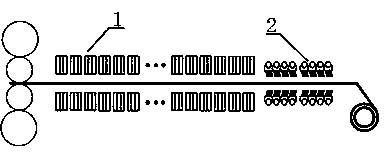

[0028] The low-cost hot-rolled dual-phase steel plate with thick gauge and uniform structure based on the post-mounted ultra-fast cooling technology of the present invention is smelted and cast into slabs according to the set composition. 0.50%Si, 1.20~1.50%Mn, Cr≤0.40%, P≤0.012%, S≤0.002%, the balance is Fe and unavoidable impurities.

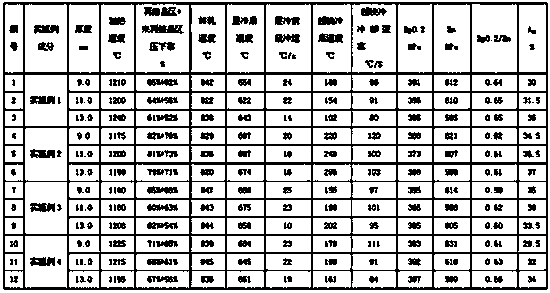

[0029] Table 1 is the measured chemical composition of specific examples of the present invention (by weight percentage, the balance is Fe and unavoidable impurities).

[0030] Table 1 Chemical composition of specific embodiments of the present invention (Wt.%)

[0031]

[0032] Example process: put the billet of the composition shown in Examples 1 to 4 in a heating furnace and heat it to 1160~1240 ° C, and adopt rolling including austenite recrystallization zone (reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com