Method for eliminating cracks in additive manufacturing metal material

A metal material and additive manufacturing technology, which is applied in the field of crack elimination in additive manufacturing metal materials, can solve problems such as changing alloy composition, affecting alloy performance, and inability to process printed parts, so as to achieve tensile strength and elongation. The effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for eliminating cracks in additive manufacturing metal materials, and samples A and B are processed;

[0046] Put the samples A and B into the heat treatment furnace, and after vacuuming the furnace body, pass high-purity argon gas to suppress the oxidation of the samples. The samples are heated up to 1285°C with the furnace, and the heating rate is 10°C / min, rising to the target temperature After holding for 5 minutes, then cooling to 1200°C at a rate of 2°C / min, that is, the pressure of hot isostatic pressing at this time is 0 MPa, and finally cooling to room temperature with the furnace, and taking out the sample;

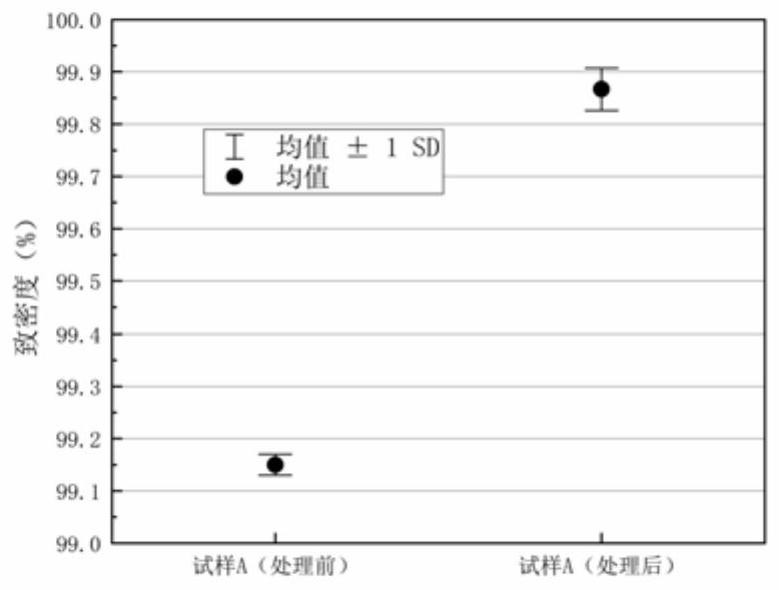

[0047] The density value of the sample A (after treatment) was tested by the Archimedes density test method, and its density was increased to 99.86% at this time. figure 2 The density of sample A before and after treatment was compared.

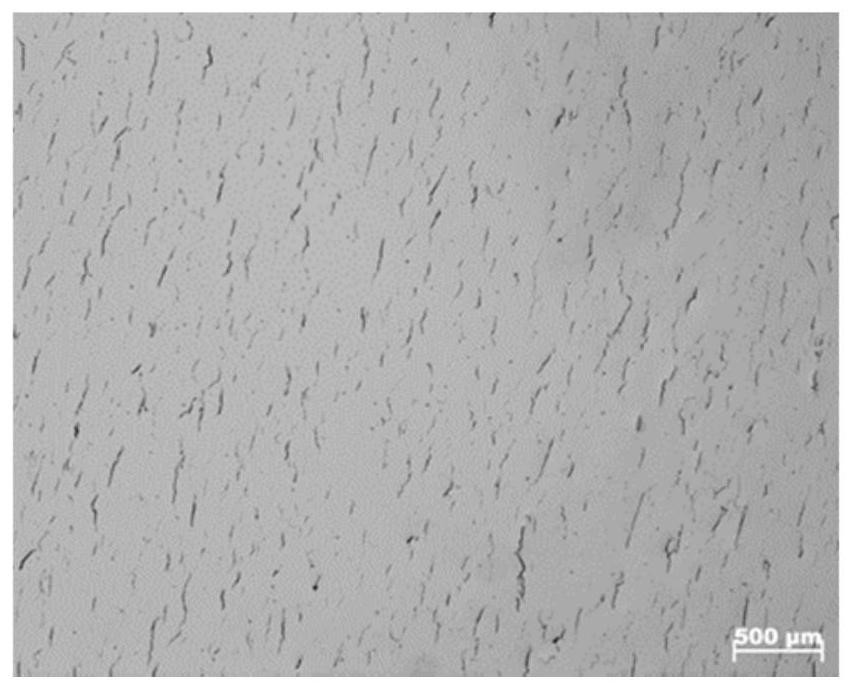

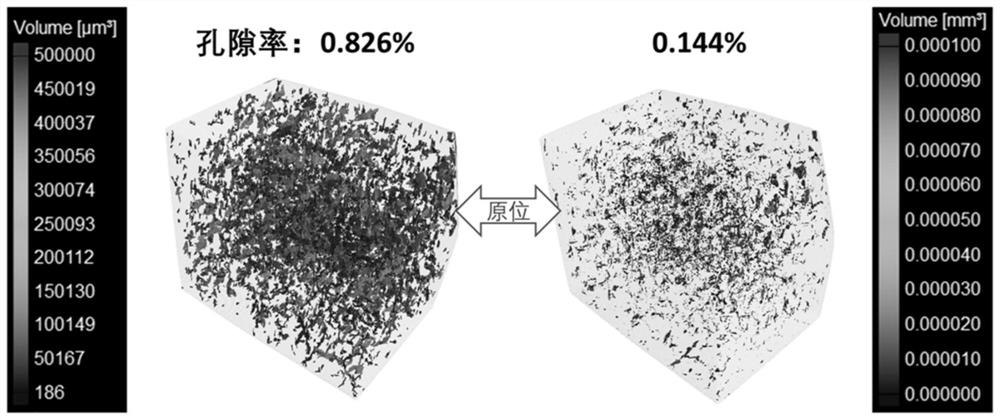

[0048] The internal defect space of sample B (after treatment) was analyzed by x-C...

Embodiment 2

[0051] This embodiment provides a method for eliminating cracks in additive manufacturing metal materials, and samples C and D are processed;

[0052] Put the samples C and D into the heat treatment furnace. After vacuuming the furnace body, pass high-purity argon gas to suppress the oxidation of the samples. The samples are heated up to 1285°C with the furnace, and the heating rate is 10°C / min, and they are kept at the target temperature. After 5 minutes, the furnace body was pressurized by air pressure, the isostatic pressure was 7MPa, and the pressurization rate was 2.5MPa / min. Then keep the pressure constant and cool to 1200°C at a rate of 2°C / min, then cool to room temperature with the furnace, release the pressure, and take out the sample;

[0053] The density value of sample C (after treatment) was tested by the Archimedes density test method, and its density was increased to 99.99% at this time. Figure 4 The density of sample C before and after treatment was compared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com