Method and cooling system for improving comprehensive mechanical property of normalized steel plate

A technology of comprehensive mechanics and cooling system, which is applied in the field of improving the comprehensive mechanical properties of normalized steel plates, methods and cooling systems, can solve the problem of not considering the influence of heating on the performance of steel plates, easy bonding of oxide scales on the surface of steel plates, and poor cooling of steel plates. Uniformity and other issues, to achieve the effect of improving comprehensive mechanical properties, increasing yield strength, and stabilizing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking the steel grade Q370qE as an example, the method of improving the comprehensive mechanical properties of the normalized steel plate is described in detail. The specification of the steel grade Q370qE: thickness 60mm×width 2500mm×length 12000mm.

[0041] The first step: use the empirical formula to calculate the Ac3 temperature point of the steel plate, Andrews formula:

[0042] Ac3=910-203C 1 / 2 -15.2Ni+44.7Si+104V+31.5Mo+13.1W,

[0043] Applicable to C≤0.6wt%, Mn≤4.9wt%, Cr≤5wt%, Ni≤5wt%, Mo≤5.4wt%, (wt% mass percentage), determined according to the calculated value of Ac3 to obtain the steel type Q370qE heating The target temperature is 880±10°C.

[0044] Step 2: The thickness of the steel plate calculates the heating time required for the steel plate to reach the target temperature of normalizing heating. The formula is 1.3~1.6min / mm×steel plate thickness, and the heating time is the running time of the heating zone;

[0045]Comprehensively considering the t...

Embodiment 2

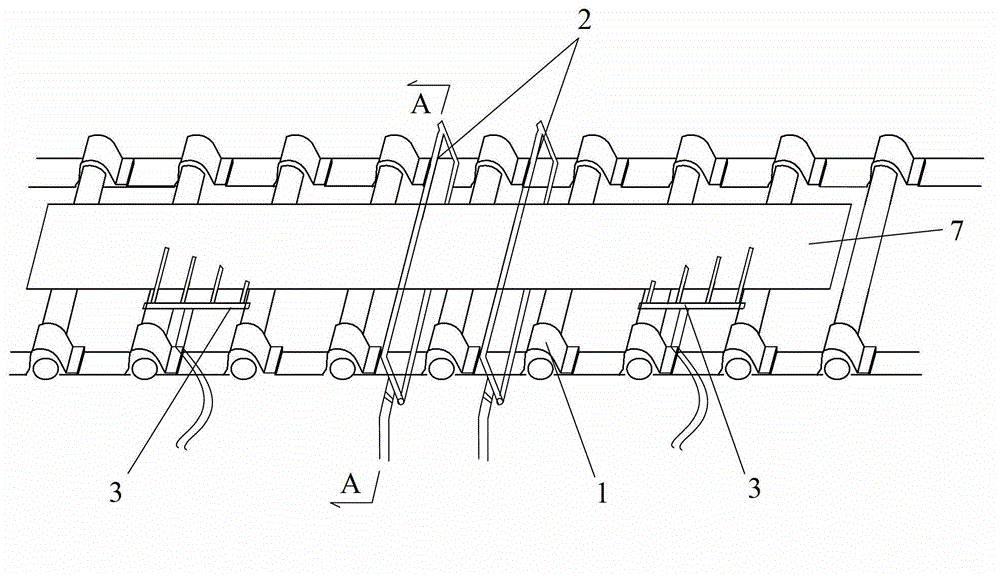

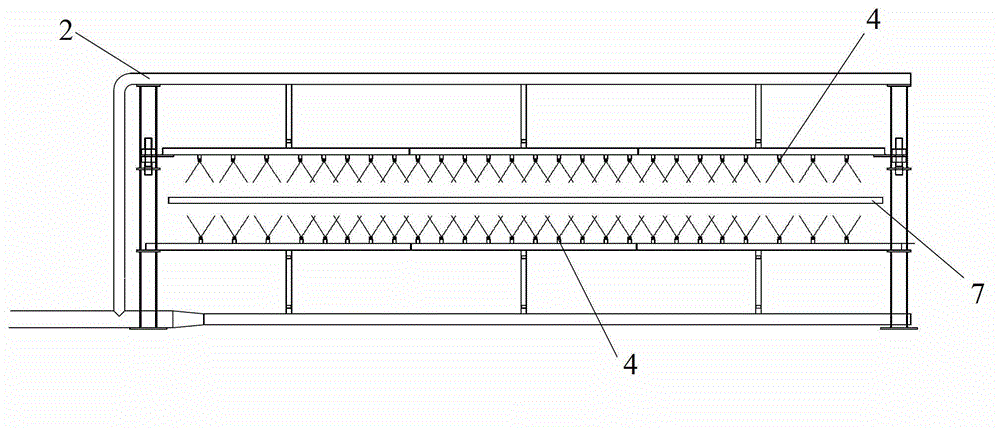

[0063] Such as Figure 1~6 As shown, a cooling system for improving the comprehensive mechanical properties of normalized steel plates includes a roller table 1, and a water mist cooling device 2 is arranged on the upper and lower sides of the roller table 1, and the sides of the roller table 1 located before and after the water mist cooling device 2 are equipped with The compressed gas purging device 3 with air outlet toward the inner side of the roller table 1, the water mist cooling device 2 includes multiple groups of nozzles 4 arranged above and below the roller table 1, and each group of nozzles 4 is arranged axially along the roller table 1, and from the roller From the edge of the track 1 to the center of the roller track 1, the distance between the nozzles 4 decreases gradually. The steel plate 7 running on the roller table 1 is the steel plate to be cooled through normalizing treatment in the normalizing furnace.

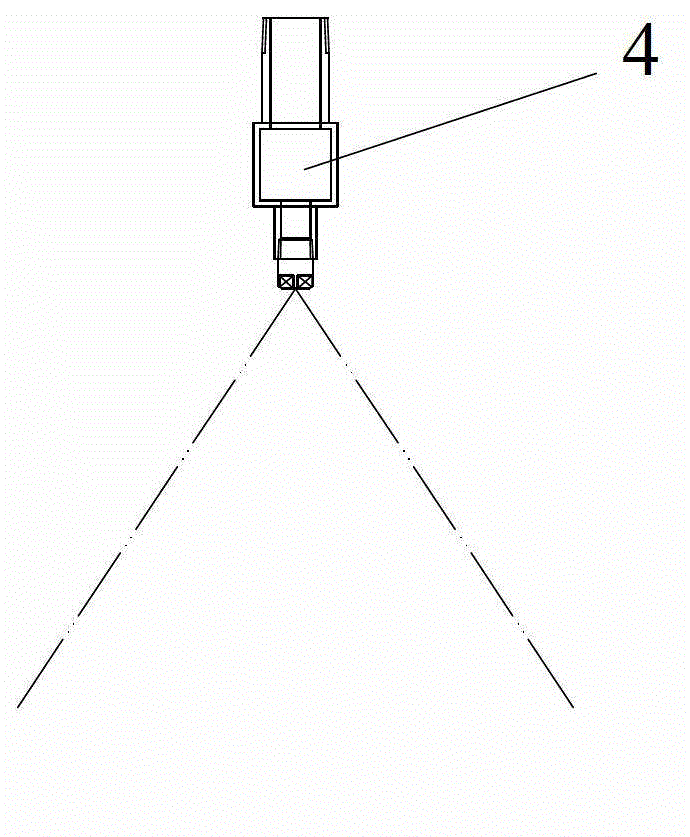

[0064] Such as Figure 4 , The nozzle 4 used in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com