Novel Mg-Y-Nd-(La+Ce)-Zr biodegradable magnesium alloy and manufacturing method thereof

A magnesium alloy and a new technology are applied in the field of biomedical rare earth magnesium alloys, new Mg-Y-Nd--Zr biodegradable magnesium alloys and their preparation, which can solve the problems of less research on the degradability of rare earth magnesium alloys, etc. Achieve the effects of excellent mechanical properties and corrosion resistance, stable performance and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

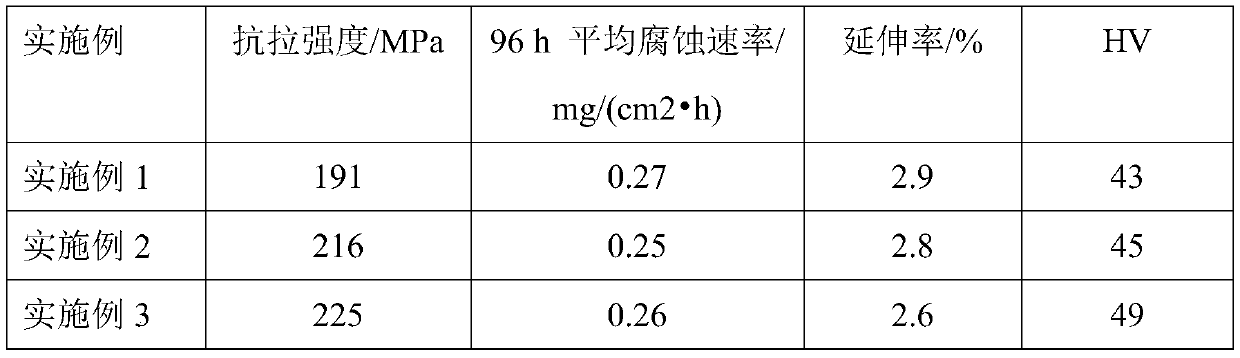

Examples

Embodiment 1

[0028] Its production process is as follows:

[0029] Batching - melting and casting - annealing - extrusion - finished product.

[0030] The specific process is: use a vacuum medium frequency induction furnace for melting, and distribute the ingredients according to the ingredients shown in Table 1. In the resistance furnace, preheat the crucible and mold to above 150°C, cool to 70°C-80°C, coat the ZnO coating, and then heat the crucible To 700°C, put in magnesium ingots and sprinkle covering agent, heat up to 850°C after the magnesium ingots melt, add master alloys Mg-20%Y, Mg-20%Nd and Mg-12%La-8%Ce , remove slag after stirring, then sprinkle into covering agent, keep warm for 20 minutes, heat up to 850℃~950℃, add Mg-30%Zr alloy, stir, remove slag, sprinkle solvent again, keep warm for 30 minutes and lower the temperature to 860°C, add refining agent for refining, let stand for 30 minutes, cool down to about 840°C, pour the melt into a steel mold with a preheating temperat...

Embodiment 2

[0032] Its production process is as follows:

[0033] Batching - melting and casting - annealing - extrusion - finished product.

[0034] The specific process is: use a vacuum medium frequency induction furnace for melting, and distribute the ingredients according to the ingredients shown in Table 1. In the resistance furnace, preheat the crucible and mold to above 150°C, cool to 70°C-80°C, coat the ZnO coating, and then heat the crucible To 700°C, put in magnesium ingots and sprinkle covering agent, heat up to 850°C after the magnesium ingots melt, add master alloys Mg-20%Y, Mg-20%Nd and Mg-12%La-8%Ce , remove slag after stirring, then sprinkle into covering agent, keep warm for 20 minutes, heat up to 850℃~950℃, add Mg-30%Zr alloy, stir, remove slag, sprinkle solvent again, keep warm for 30 minutes and lower the temperature to 860°C, add refining agent for refining, let stand for 30 minutes, cool down to about 840°C, pour the melt into a steel mold with a preheating temperat...

Embodiment 3

[0036] Its production process is as follows:

[0037] Batching - melting and casting - annealing - extrusion - finished product.

[0038] The specific process is: use a vacuum medium frequency induction furnace for melting, and distribute the ingredients according to the ingredients shown in Table 1. In the resistance furnace, preheat the crucible and mold to above 150°C, cool to 70°C-80°C, coat the ZnO coating, and then heat the crucible To 700°C, put in magnesium ingots and sprinkle covering agent, heat up to 850°C after the magnesium ingots melt, add master alloys Mg-20%Y, Mg-20%Nd and Mg-12%La-8%Ce , remove slag after stirring, then sprinkle into covering agent, keep warm for 20 minutes, heat up to 850℃~950℃, add Mg-30%Zr alloy, stir, remove slag, sprinkle solvent again, keep warm for 30 minutes and lower the temperature to 860°C, add refining agent for refining and let it stand for 30 minutes, cool down to about 840°C, pour the melt into a steel mold with a preheating te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com