Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, to achieve the effects of slowing down hysteresis, improving efficiency and improving crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

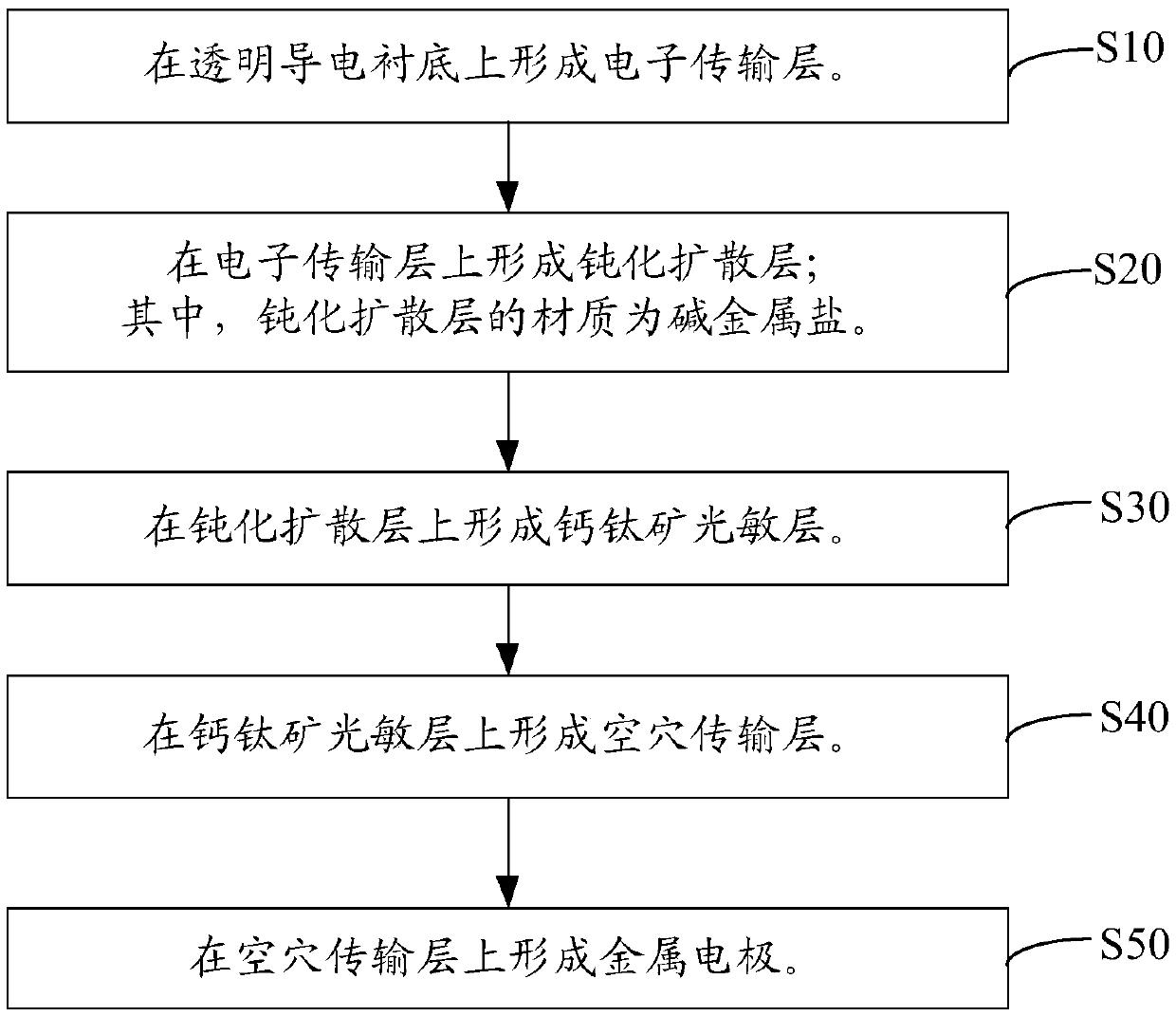

[0059] See image 3 , the preparation method of the perovskite solar cell of one embodiment of the present invention comprises the following steps:

[0060] S10, forming an electron transport layer on the transparent conductive substrate.

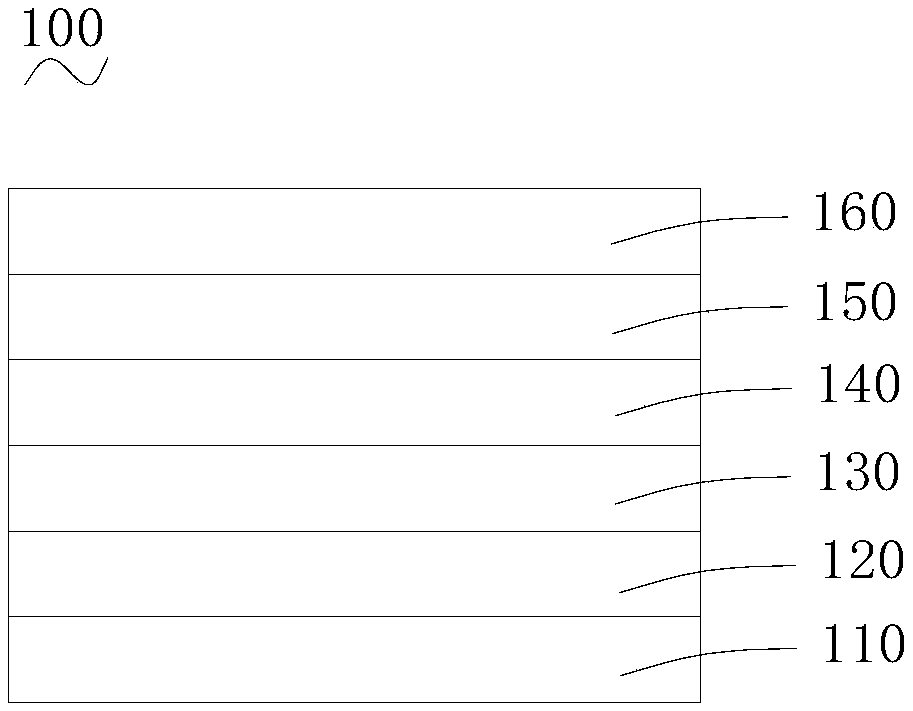

[0061] Please also see Figure 4 , the electron transport layer 120 is formed on the transparent conductive substrate 110 . The transparent conductive substrate 110 can be prepared by physical vapor deposition, evaporation or sputtering. The electron transport layer 120 can be prepared by spin coating, vacuum sputtering or electron beam evaporation.

[0062] S20, forming a passivation diffusion layer on the electron transport layer; wherein, the material of the passivation diffusion layer is alkali metal salt.

[0063] Please also see Figure 4 , a passivation diffusion layer 130 is formed on the electron transport layer 120 .

[0064] Preferably, the operation of forming a passivation diffusion layer on the electron transport layer i...

Embodiment 1

[0092] 1. Spin-coat 0.1M tin oxide quantum dot solution on a transparent conductive substrate, the spin-coating conditions are: 3000rpm, 1000m / s 2 , 30s, and then annealed at 100° C. for 10 minutes, then raised to 200° C. and annealed for 30 minutes to obtain a tin oxide electron transport layer.

[0093] 2. Spin-coat 30mg / ml KCL aqueous solution on the tin oxide electron transport layer, the spin-coating conditions are: 5000rpm, 2500m / s 2 , 30s, and then annealed at 120° C. for 15 minutes to obtain an alkali metal salt passivation diffusion layer.

[0094] 3. Spin-coat the 1.5M perovskite solution on the passivation diffusion layer, the spin-coating conditions are: 3000rpm, 1500m / s 2 , 7s, get a relatively uniform perovskite liquid film (wet film) after spin coating, then immediately put it into the air pumping device, pump air for about 30s, remove most of the solvent, and get a relatively dry and completely crystallized perovskite thin film, and then make the perovskite t...

Embodiment 2

[0098] The difference between Example 2 and Example 1 is that the annealing method of the perovskite film in step 3 is not directly contacted with the heating plate for heating, but a conventional heating method, that is, the perovskite film faces upward and the transparent conductive substrate faces downward Contact heating plate for heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com