Method for smithing GH4169 alloy plate shaped forgeable piece in air at an approximately equal temperature

A GH4169, isothermal forging technology, applied in the field of warm forging, can solve the problems of difficulty in obtaining consolidated powder blanks, many technical problems and great difficulties, and achieve the effects of excellent structure and performance, reducing forging costs and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] To implement the near-isothermal forging method of the GH4169 alloy disc forging in the air of the present invention, it is necessary to provide a forging furnace, a rolling mill, a forging press with a forging die and a ring heating furnace, and cast or forged GH4169 alloy original bars.

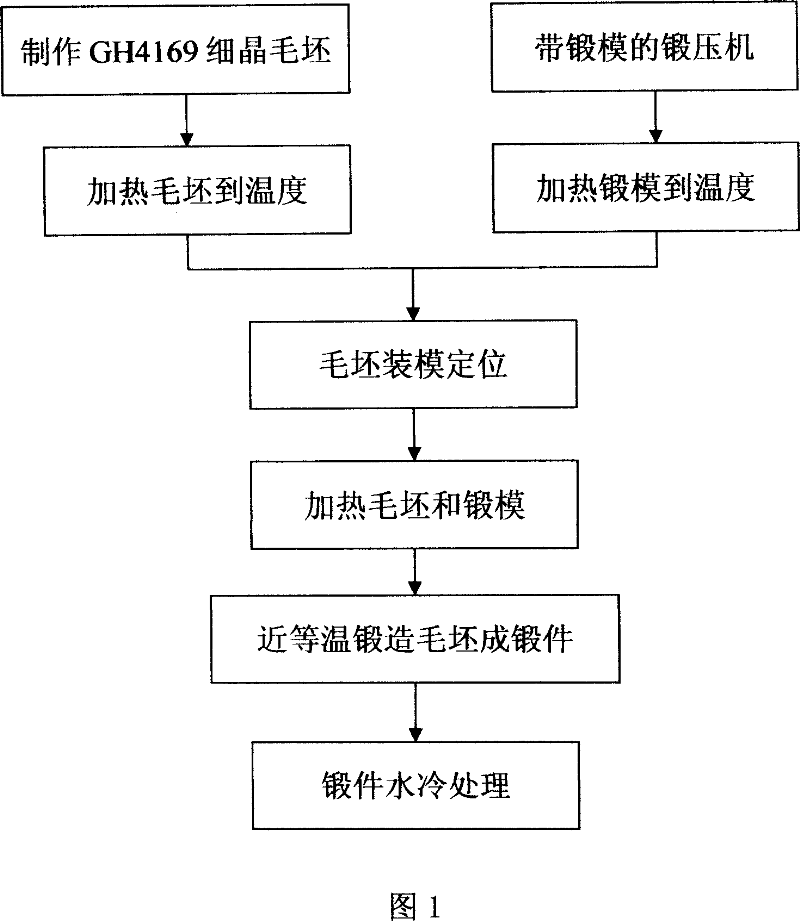

[0029] Figure 1 shows the process flow of nearly isothermal forging of GH4169 alloy disc forging in air.

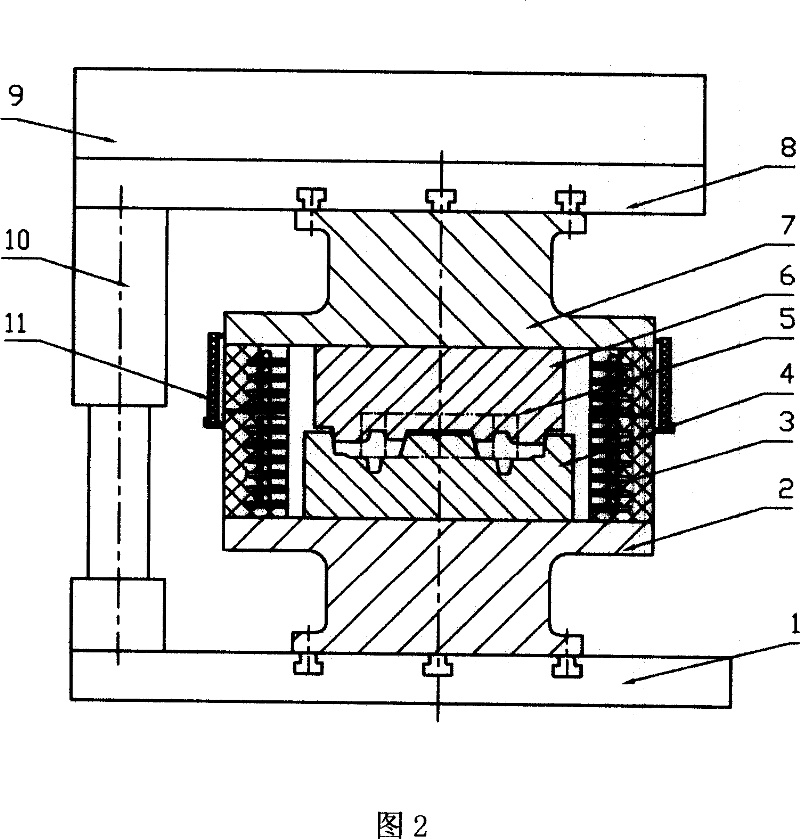

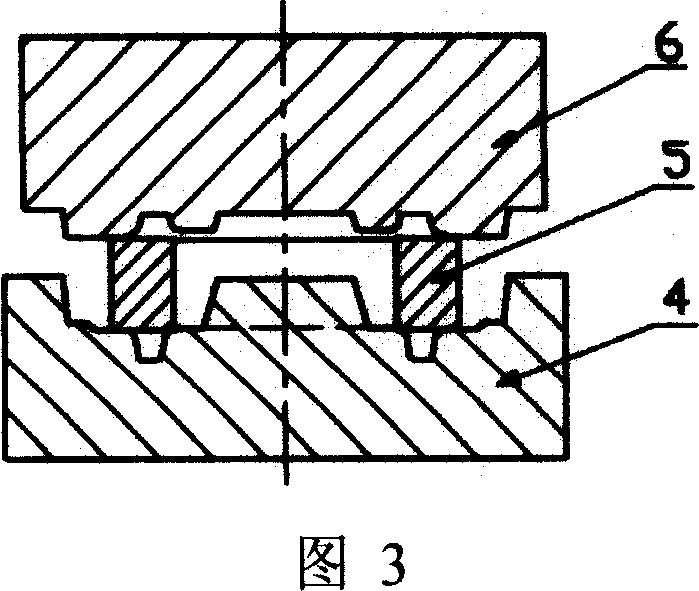

[0030] Fig. 2 shows the assembling situation of the forging press 9, the upper forging die 6, the lower forging die 4 and the annular heating furnace 3 for implementing the near isothermal forging method of the present invention, on the workbench 1 of the forging press 9 The lower anvil 2 and the lower forging die 4 are fixedly installed, the worktable 1 is connected with the slider 8 through the guide column 10, the slider 8 can slide up and down on the guide column 10, and the upper anvil 7 is fixedly installed under the slider 8 in turn and upper forging die 6; an annular hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com