Nanocrystalline high-chromium cast-iron composite nucleating agent for engineering machinery as well as preparation method and application method thereof

A composite inoculant and high-chromium cast iron technology, which is applied in the field of cast iron alloys, can solve the problems that the comprehensive mechanical properties of high-chromium cast iron alloys cannot be effectively improved, and the grain and microstructure refinement effect of the cast iron alloy matrix is not ideal. The effects of matrix grain refinement, increased interface energy, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The weight ratio by element composition is Fe:Ti:B=0.37~0.47:3.35~0.45:0.14~0.22, take the required pure Fe, pure Ti block and B powder, and weigh the pure Fe, pure Ti block and B powder in a vacuum electric arc furnace to smelt into a button-shaped alloy ingot to obtain a Fe-Ti-B master alloy. The refining process is well known.

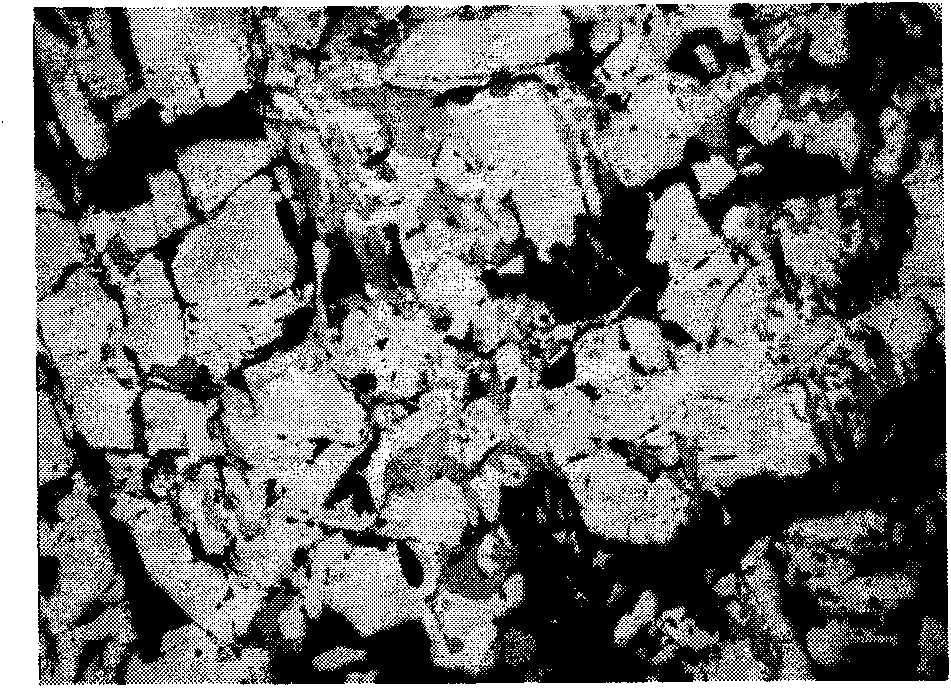

[0047] figure 1 The metallographic diagram of the Fe-Ti-B master alloy obtained for the present embodiment, figure 1 It can be seen that the grain size of the Fe-Ti-B master alloy is 50-100 μm.

Embodiment 2

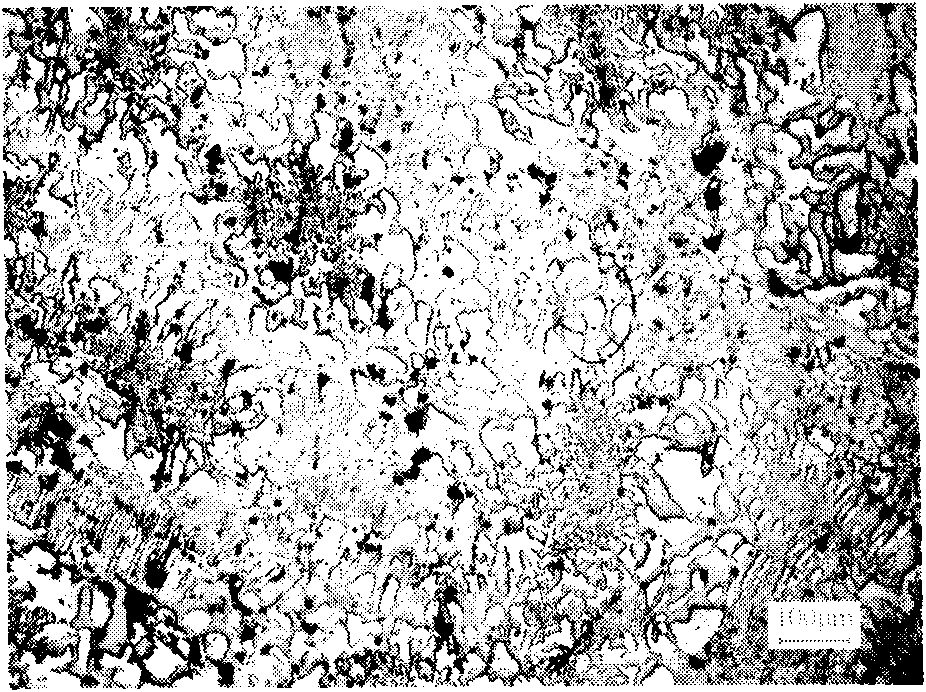

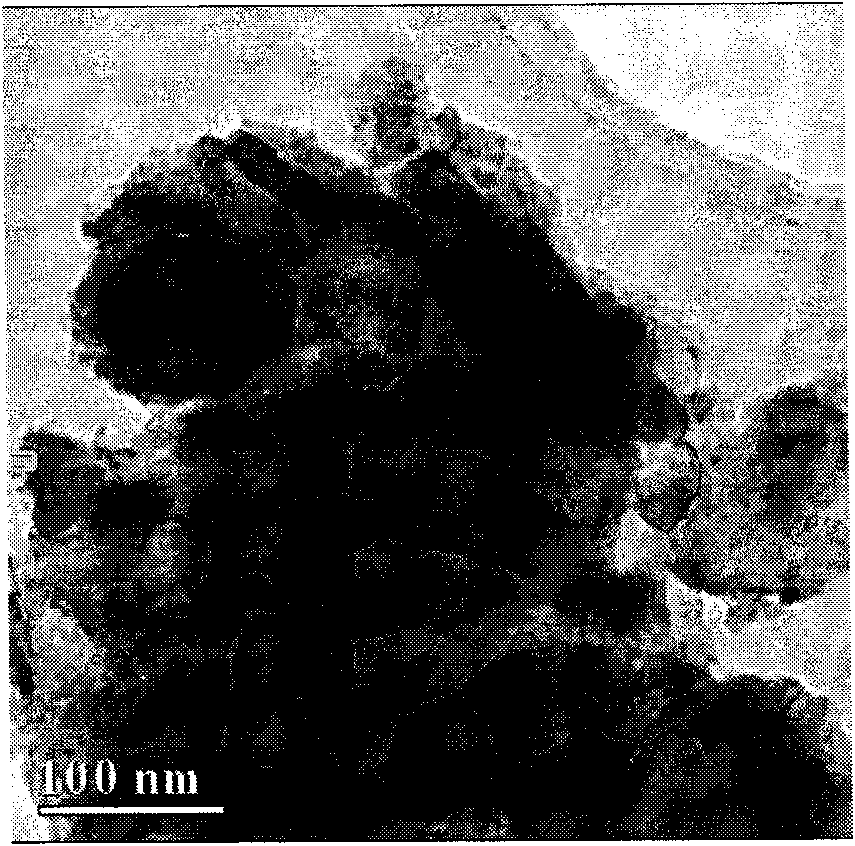

[0050] Weigh 1000 grams of Fe-Ce-Si-Ca master alloy and 100 grams of Fe-Ti-B master alloy, break them into small pieces, put them in the water-cooled copper crucible of the vacuum quenching furnace, adjust the electrode position, make it with The distance between the alloy particles in the crucible is 0.75mm, close the furnace door, the inlet and outlet and the air release valve, and vacuumize until the vacuum degree is higher than 3.8×10 -3After Pa, wash the furnace with argon gas, then fill it with argon gas until the pressure is 0.04Pa, adjust the arc current to gradually increase to 500A after arcing, melt the above alloy, and when the above alloy is completely melted into a liquid state, tilt the crucible to make the alloy The liquid is led to the high-speed rotating water-cooled molybdenum wheel through the flow channel. The surface temperature of the molybdenum wheel is 10°C. After the molten liquid alloy contacts the molybdenum wheel, it solidifies rapidly. The edge spe...

Embodiment 3

[0052] Take by weighing 1200 grams of Fe-Ce-Si-Ca master alloy and 80 grams of Fe-Ti-B master alloy, they are broken into fritters, put into the water-cooled copper crucible of vacuum quenching furnace, and fritters are placed on the bottom, relatively Put the big piece on top, adjust the position of the electrode so that the distance between it and the alloy particles in the crucible is 1.0 mm, close the furnace door, the inlet and outlet, and the air release valve, and evacuate until the vacuum degree is higher than 3.8×10 -3 After Pa, wash the furnace with argon, then fill it with argon until the pressure is 0.045Pa, adjust the arc current to gradually increase to 550A after arcing, melt the above alloy, and when the above alloy is completely melted into a liquid state, tilt the crucible to make the alloy The liquid is led to the high-speed rotating water-cooled molybdenum wheel through the flow channel. The surface temperature of the molybdenum wheel is 12.5°C. After the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com