Titanium dioxide film hydrogen sensor and preparation method thereof

A titanium dioxide and sensor technology, applied in the field of hydrogen sensors, can solve the problems of small resistance change of hydrogen sensors, low detection limit of hydrogen, hidden safety hazards, etc., and achieve the effects of excellent detection sensitivity and stability, reducing leakage current and increasing density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

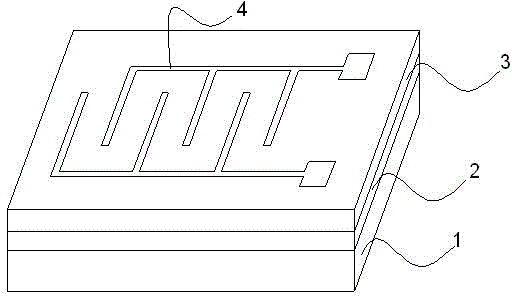

[0020] The present invention provides a kind of preparation method of titanium dioxide thin film hydrogen sensor on the other hand, it comprises the following steps:

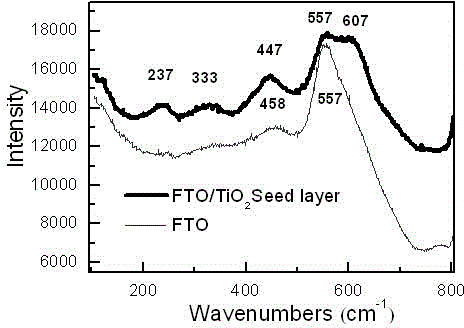

[0021] A. Provide FTO conductive glass layer 1, and pre-deposit a layer of [002]-oriented TiO on the surface of FTO conductive glass layer 1 by magnetron sputtering method 2 seed layer 2;

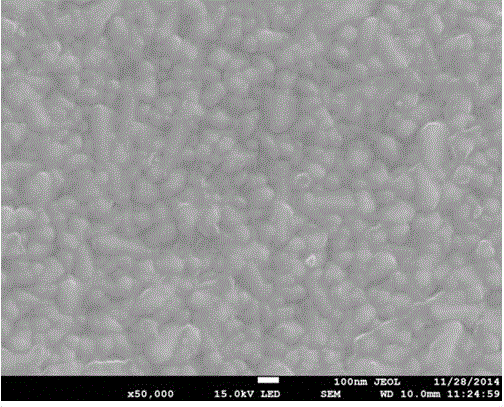

[0022] B. Using the hydrothermal method, in the TiO 2 TiO grows on the surface of seed layer 2 2 Nano-array film layer 3;

[0023] C. On TiO 2 Interdigital electrodes 4 are arranged on the surface of the nano-array film layer 3 .

[0024] Preferably, said step B also includes, for TiO 2 The nano-array film layer 3 is annealed in an inert atmosphere. Further preferably, the annealing temperature is 380-420° C., and the annealing time is 20-30 min. Specifically, Ar gas is used as the inert atmosphere. By annealing, TiO can be optimized 2 The interface performance of the nano-array film layer 3 reduces the interface sta...

Embodiment 1

[0038] Clean the FTO conductive glass layer 1: put the FTO conductive glass layer 1 into acetone, absolute ethanol, and deionized water successively for 20 minutes, and dry it for later use;

[0039] Install Ti 2 o 3 Target and substrate: Ti 2 o 3 The target is installed at the cathode target position of the magnetron sputtering system, and the distance between the target and the substrate is adjusted to 60mm. The FTO conductive glass layer 1 is placed at the substrate position and water-cooled;

[0040] Clean Ti2 o 3 Target material: vacuum to 10 -4 In the Pa order of magnitude, 50sccm argon and 1sccm oxygen are introduced into the magnetron sputtering chamber, the deposition pressure of the chamber is controlled to be 1Pa, and the radio frequency Ti is adjusted. 2 o 3 The power of the target is 120W, and the target is glow-cleaned for 10 minutes;

[0041] Sputtering deposition and annealing: After cleaning, adjust the RF Ti 2 o 3 The power of the target is 120W, and...

Embodiment 2

[0047] Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is: through hydrothermal synthesis of TiO 2 After the nanoarray film layer 3, the TiO 2 The nano-array thin film layer 3 was annealed at 400° C. for 20 min under the protection of Ar atmosphere.

[0048] TiO at 25±5°C 2 Gas sensor for detection. The gas sensitivity test results show that the response time and recovery time of the sensor are both short. In the range of hydrogen concentration of 1-1000ppm, the response time of the sensor is about 10s, and the average recovery time of the sensor is 134s in the range of hydrogen concentration of 1-80ppm. , the hydrogen concentration is 100-1000ppm, and the sensor recovery time is faster, 36-66s. TiO 2 It exhibits very good gas-sensing characteristics at low concentrations. When the hydrogen concentration is 1ppm, the resistance value can drop by 4%. After the resistance value drops to the minimum, it can quickly stabilize at this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com